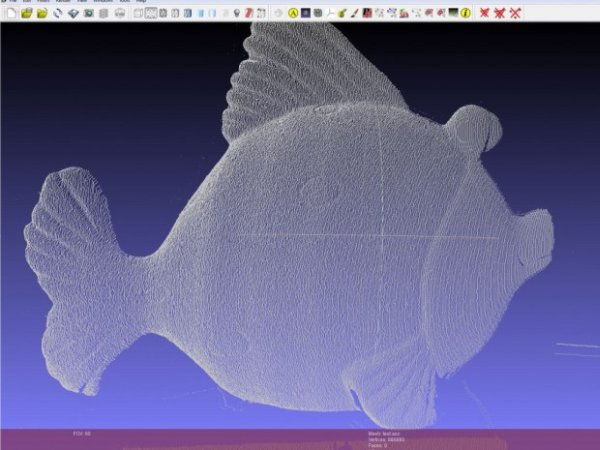

Maker Alessandro Grossi sent us this great DIY build for a 3D scanner built using a laser, a DSLR, and an Arduino controller. Allesandro is a Mechanical Engineer, holding a Ph.D. in product design. His day job involves helping designers and manufacturing firms develop and optimize products by means of FEM analisys and Computational fluid dynamics. This is just what he does for fun. You can read the project and more on his own site, metaingegneria.com.

Here’s Alessadro’s project description:

A line laser is a laser equipped with a cylindrical lens, in this case I used a red laser, but other colors can be used, like green or blue. The lens opens the beam shaping it into a plane. The one I used in this experiment is characterized by a nominal power of 100mW (not up to standard in Italy, I think the max allowed power is 5mW) but the beam does not remain focused in a single ray, it is extended in a plane, so the intensity quickly drops below dangerous levels.

The principle behind this scanner is the typical of a line scanner. A laser beam intercepts the object to be measured and a camera, positioned at a known angle and distance shoots a series of images. With some trigonometry considerations and optic laws it is relatively easy to reconstruct the Zeta dimension, the measurement of the distance between the object and the camera.

Commercial systems based on this principle, named line scanner or profilometers, are used in industries and are typically characterized by a high frame rate (even 200 or more frames per second) and a strength suitable for industrial uses. An industrial profilometer price ranges from a few thousand Euros to several tens of thousands of Euros. The cost of the components for the system I propose here does not exceed 100/150 €, if you already have an SLR.

Step #1: Holder arm for laser and DSLR

- Using hot glue, welding or the method you prefer, connect the camera and the laser ball head at an arm whose length is about 40/50 cm. When the three parts are connected (laser head, arm and camera) locate the assembly center of gravity (approximately). In that position drill an hole for the stepper motor shaft. It would be geometrically easier to use a panoramic head, which grants the ability to turn the system around the lens nodal point, but that would require a more rigid system, certainly not achievable with a simple piece of chipboard, and a shaft simply forced in an hole.

- Pay attention to obtain the parallelism between the hole axis, the vertical axis of the image captured by the camera and the laser plane! I suggest you make the hole that houses the motor shaft using a drill press, or, if you have access to a lathe, you could realize a collar to ensures the orthogonality between the motor axis and the arm. Moreover, the laser plane will be, in turn, perpendicular to the plane of the arm and the camera must be perfectly horizontal and leveled. Assembling everything you should get something that looks like the system I show in the picture. I’m waiting for pictures of your own solutions! mail me at [email protected]

Step #2: Rotation and camera synchronization

- The second step is to put everything in rotation and to synchronize the camera. The fastest and easiest way I’ve found to achieve this synchronization is to use an Arduino to mimic the infrared remote control and to control the stepper motor. -the infrared led is connected to pin 13 (and ground) -the 3 inputs of the driver (pul, dir, enable) are connected to pins 10,11 and 12

- the Arduino code I used is:/*

Stepper Motor Control +camera control

*/

int pinIRLED = 13; // infrared led

int pul = 10;

int dir = 11;

int enbl = 12;

int passi = 4; // numero passi su 12800

int intervallo = 3; // intervallo tra i passi

void setup() {

pinMode(pinIRLED, OUTPUT);

pinMode(pul, OUTPUT);

pinMode(dir, OUTPUT);

pinMode(enbl, OUTPUT);

digitalWrite(enbl, HIGH);

}

void pulseON(int pulseTime) {

unsigned long endPulse = micros() + pulseTime; // create the microseconds to pulse for

while( micros() < endPulse) {

digitalWrite(pinIRLED, HIGH); // turn IR on

delayMicroseconds(13); // half the clock cycle for 38Khz (26.32×10-6s) – e.g. the ‘on’ part of our wave

digitalWrite(pinIRLED, LOW); // turn IR off

delayMicroseconds(13); // delay for the other half of the cycle to generate wave/ oscillation

}

}

void pulseOFF(unsigned long startDelay) {

unsigned long endDelay = micros() + startDelay; // create the microseconds to delay for

while(micros() < endDelay);

}

void takePicture() {

for (int i=0; i < 2; i++) {

pulseON(2000); // pulse for 2000 uS (Microseconds)

pulseOFF(27850); // turn pulse off for 27850 us

pulseON(390); // and so on

pulseOFF(1580);

pulseON(410);

pulseOFF(3580);

pulseON(400);

pulseOFF(63200);

} // loop the signal twice.

}

void loop() {

// ciclo per dare gli step al driver dello stepper

for (int ii=0; ii<passi; ii++){

digitalWrite(pul, HIGH);

delay (intervallo);

digitalWrite(pul, LOW);

delay (intervallo);

}

delay(1600); // questo intervallo è necessario per garantire che il braccio abbia terminato le oscillazioni prima di riprendere l’immagine

takePicture(); // take the picture

delay(200);

} - Now the assembly is ready and it should work more or less like this: Watch video here.

For more detail: DIY 3D Laser Scanner Using Arduino