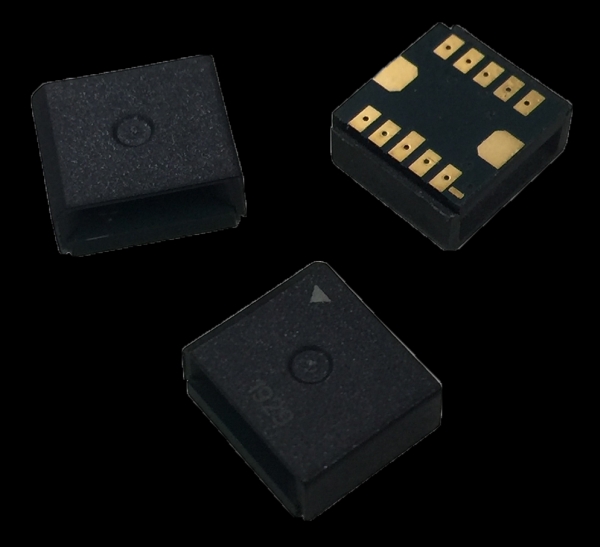

Posifa Technologies announced the new PAV3000 series of economical, high-performance air velocity sensors with digital I2C output and a surface-mount footprint for thermal management and filter monitoring in even the most space-constrained locations. Unlike thermistor-based solutions, the PAV3000 has a MEMS sensor core that is minimally affected by ambient temperature changes and which provides instant real-time feedback on proper air flow at critical locations.

Air velocity data perfectly complement temperature information to provide the best insight into thermal efficiency. Because the PAV3000 helps identify areas that require unusually high air flow to maintain stable temperatures, layouts for rack enclosures with air cooling – such as those found in data centers – can be modified to reduce cooling demands for increased energy savings. In applications such as HVAC systems, air velocity measurements can be used to determine when filters need to be replaced. This ensures hardware is adequately protected during heavy use, and it allows customers with light usage requirements to benefit from extended change intervals.

Key Specifications And Benefits:

- Digital I2C output

- Compact, robust surface-mount package

- Solid-state sensing core

- No moving parts

- Eliminates the need for a surface cavity or fragile membrane

- Resistant to clogging and pressure shock

- Feature Posifa’s third-generation thermal flow die

- Measure air velocity at 7 m/s (PAV3005V) and 15 m/s (PAV3015V)

- Extremely fast response times of 125 ms typical

- Excellent repeatability of 1 % FS

- High accuracy of 5 % FS

- Supply voltage from 5 VDC to 5.5 VDC

- Supply current of 20 mA

- Operating temperature range of -25 °C to +85 °C temperature range

PAV3000 series devices feature Posifa’s third-generation thermal flow die, which uses a pair of thermopiles to detect changes in temperature gradient caused by mass flow. The result is excellent repeatability of 1% FS and an accuracy of 5% FS. The solid-state thermal isolation structure on the sensor die eliminates the need for a surface cavity or the fragile membrane used in competing technologies, making the sensor resistant to clogging and pressure shock.