Description

What unique about this motor design is that the stator is printed on a 4-layer PCB board. The six stator poles are spiral traces wounded in a star configuration. Although these coils produce less torque compared to an iron core stator, the motor is still suitable for high-speed applications.

The current prototype has a 3d printed rotor with a 16mm diameter.

Details

My PCB-Motor is made from a 6-pole stator printed on a 4-layer PCB and a 4-pole 3d printed rotor. Its has an outer diameter of 16mm and is rated at 1 watt.

I had this idea when I was trying to design a small compact drone. The PCB motor is much cheaper than other micro brushless motors and also easier to assemble. My goal is to make the rotor part of the BOM and mounted just like any other component on a PCB.

VIDEO

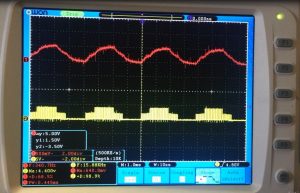

My plan for speed controlling the PCB Motor was to implement a sensorless back-emf speed controller, which works just like every other brushless ESC. It measures the time it takes to detect the zero-crossing point from the under-driven phase, and adjust the commutation waveforms according. However, during testing the back-emf generated in the windings of the PCB motor was a little weak.

Plan-B is to use a hall sensor to implement the closed loop speed controller. This will be a little more pricey but will also include positional sensing.

New Rotor

Carl Bugeja • 03/05/2018 at 00:33 • 1 comment

This is my new 3D printed rotor prototype with a snap-hook shaft and press-fit circular magnets!

Read more: PCB Motor – A smaller and cheaper brushless motor.