Modern battery operated portable devices use smart battery packs. Every new development of an electronic medical device must follow strict design flow defined by world-wide or local regulatory

directives. The development process of any such device using smart battery pack requires specific operating conditions to meet the testing criteria. When smart battery pack is one of the main power sources the host system should be tested with several battery states. The testing is necessary during development, validation and later in production testing.

Testing process

During development cycle test specifications and pass criteria must be provided base on the product specification. Production test also could be treated as a simplified qualification test, because it has to follow several standard regulations. Efficient production cycle for every product has time constraints on each station. The target of production test is deliver quality products, but it could not go through all engineering details and should be finished within limited time.

Battery cell

There are several problems when using real battery cells for such tasks:

- limited charge and discharge rates,

- limited battery cell charge cycles,

- charge maintenance,

Every battery cell has maximum charge and discharge rates, which must not be exceeded to avoid risks of battery damage, overheating and fire. Charge and discharge rates then limit shortest possible times to set the battery cell to defined state within charge and discharge cycle. As it could have limited usability for development, long testing times are not acceptable for production process and should be avoided.

Next problem with cycling real battery cells is limited number of charge/discharge cycles. Good lithium cell could have about 1000 charge cycles, which is too low for serious production.

And finally, every battery cell needs some maintenance when not in use to keep it in shape and within expected specifications.

Battery fuel gauge

The battery cell usefulness is hampered by the fact that it cannot communicate with the hosting system. Battery gauge is used for capacity monitoring and reporting. The device monitors a charge and discharge activity of the battery cell and provides available time-to-empty information across a wide range of operating conditions. It communicates to the system over a HDQ one-wire or I2C serial interface. Internal registers are updated with battery cell activity and they have no possibility to set user-predefined values. This makes standard fuel gauge devices useless in testing systems.

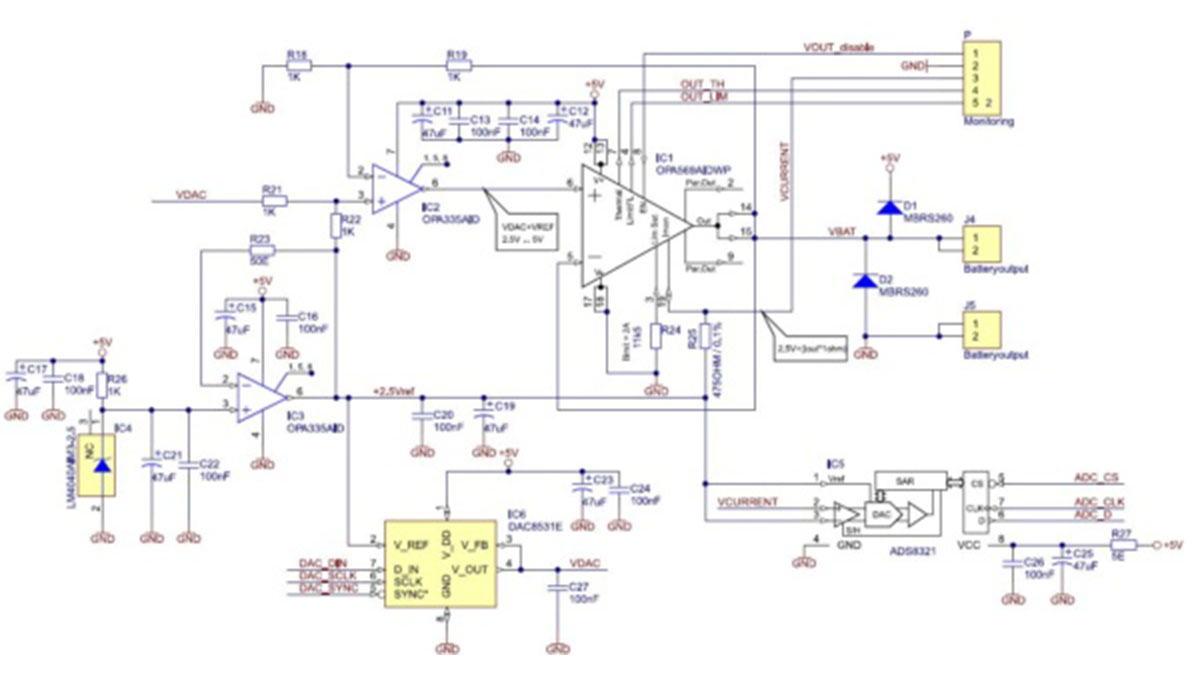

Read more: Low cost single cell L-Ion battery pack simulator