The goal of this project is to develop a low-cost bioprinter to make bioprinting more accessible to research institutions. Currently, low-end bioprinters cost approximately $10,000 while high-end bioprinters cost approximately $170,000. In contrast, our printer can be built for approximately $375.

Supplies:

Parts:

- Ramps 1.4: https://www.amazon.com/HiLetgo-Control-Printer-Su…

- Arduino mega 2560: https://www.amazon.com/Elegoo-EL-CB-003-ATmega2560…

- Stepper motor drivers: https://www.amazon.com/BIQU-Compatible-Stepper-Ste…

- Additional stepper motor (optional) https://www.amazon.com/Stepper-Motor-Bipolar-64oz-…

- Maker beam 2 in X 1 in

- Maker beam attachment hardware

- M3 screws assorted sizes

- M3 nuts x2

- 8 mm threaded rod

- 8 mm nut

- 608 bearing

- Binder clip

- Filament

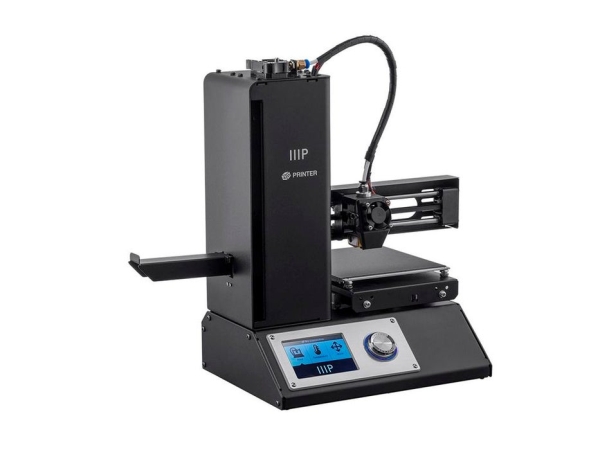

- Monoprice V2 https://www.monoprice.com/product?p_id=15365&gcli…

- Zip ties

- M3 heat set nuts 2mm width

Tools:

- Drill bits of various sizes

- Hand Drill

- Drill press

- Hacksaw

- Soldering iron + solder

- Wire stripper

- Needle nose pliers

- Hex keys various sizes

Lab supplies:

- Petri dishes ~70mm diameter

- 60 ml syringe with Luer-lock tip

- 10 ml syringe with Luer-lock tip

- Luer-lock fittings

- Tubing for fittings

- T Connector for tubing

- Centrifuge

- Centrifuge tubes 60ml

- Scale

- Weigh boats

- Autoclave

- Beakers

- Graduated cylinder

- 0.1M CaCl2 solution

- Agarose

- Alginate

- Methylcellulose

- Sucrose

Software:

- Fusion 360 or Solidworks

- Arduino IDE

- Repetier Host

- Ultimaker Cura 4

Step 1: Selecting a 3D Printer

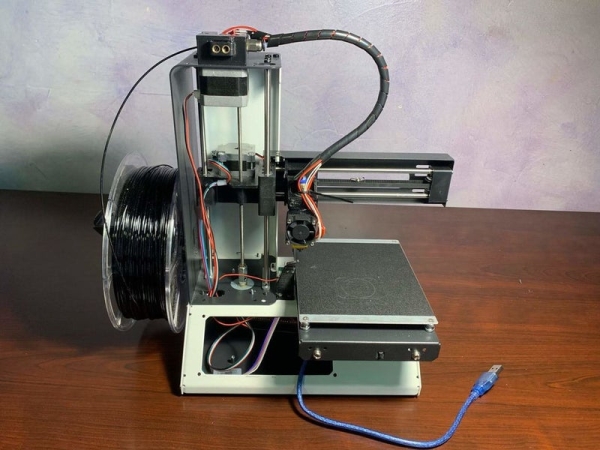

We chose the Monoprice MP Select Mini 3D Printer V2 as the starting 3D printer. This printer was selected because of its low cost and high availability. Additionally, a highly accurate 3D model of the printer was already available which made design easier. This instructable will be tailored for this specific printer but a similar process can be used to convert other common FDM printers and CNC machines.

High accuracy model: https://www.thingiverse.com/thing:2681912

Step 2: 3D Printing

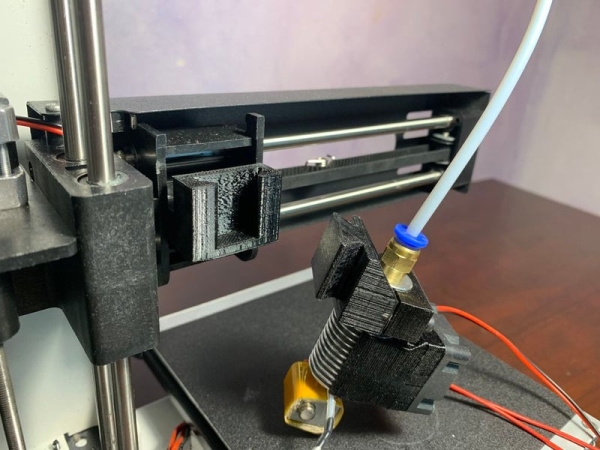

Before disassembly of the Monoprice printer, several parts need to be 3D printed for the modification of the 3D printer. There are versions of the paste extruders, one that requires epoxy and one that doesn’t. The one that requires epoxy is more compact but more difficult to assemble.

Step 3: Prepare Printer for Modification

The front tower panel, bottom cover and the control panel should be removed. Once the bottom has been removed, disconnect all electronics from the control board and remove the control board.

Step 4: Interchangeable Mount

Body 1 and Body 14 each require two heat set nuts. Body 1 is mounted to the printer frame by the two M3 bolts hidden under the belt. The bolts can be revealed by removing the belt tensioner and pulling the belt to one side.

Read more: Low Cost Bioprinter