Working with conductive fabric is fun and it’s ideal for wearables, soft circuitry, e-textiles and other projects that take advantage of it’s properties. Learning the basics will help you make design and material choices tailored to your application.

This Instructable is jam-packed with insights from using it over the years as well as favorite resources for further development. You will learn techniques, such as how to cut and attach conductive fabric and how to build the following:

- momentary switch

- linear touch sensor using resistive material

- basic LED circuit with switch

- capacitive touch piano using Arduino and CapSense

I intend this to be something you bookmark, favorite or download for later as a go-to reference. Keep in mind that to stay safe from electrical shock, this information is intended to be used with low-voltage DC projects. Please comment below to add your own insights and to ask any questions!

Contents

2) Woven, Stretch or Non-Woven?

5) Attaching Conductive Fabric : Sewing

6) Attaching Conductive Fabric : Hot Melt Adhesives

7) Attaching Conductive Fabric : Glue

8) Attaching Conductive Fabric : Double-sided Tape

10) Making Electrical Connections

11) How to Insulate Conductive Fabric

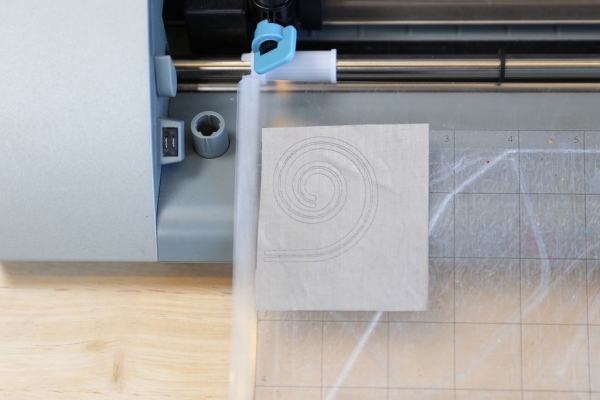

12) Traces

13) Resistors

14) Switches

15) Sensors and Variable Resistors

16) Capacitive Touch

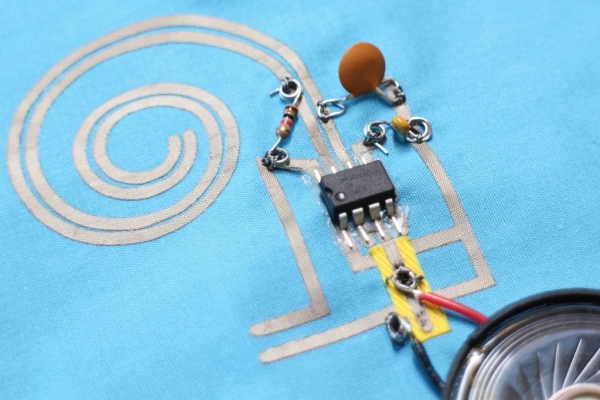

18) CapSense + Arduino Musical Circuit

19) Resources

Step 1: Why Conductive Fabric?

Unique Properties

Conductive fabric offers the softness and malleability of fabric, while also having electrical properties. It’s mainly used in projects where a soft, flexible and sometimes washable circuit is needed. It’s also great for creating low profile switches in projects where manufactured and hard conductive materials are not appropriate.

Fabric can be cut, sewn, stretched, crumpled and manipulated in other ways that hard metals, carbon and plastics can not. Knowing how it behaves can lead to unexpected creative applications and end up solving specific design problems. Not all applications need to be wearable. For example, take a look at Adrian Freed’s Tablo Fabric Drape Sensing Controller that uses the fabric’s ability to stretch and have tension as a tactile musical interface.

One of my favorite projects is the Massage Me Jacket, a video game controller that gives the wearer a massage as the gamer back + front + kicks their way through Street Fighter II. Hard switches would definitely not be suitable for this design!

IM Blanky is a beautiful example of intricate cuts and hand-built soft sensors on a large scale. It has 104 soft tilt sensors and uses traditional embroidery techniques. The creator describes it’s function as such: “By draping it over an object the blanket reproduces digitally and in real time that which it covers.” Super cool.

Biggest Downfalls

Having listed some of the great things about cond. fabric, it’s only fair to list some negatives.

I would say the biggest con is that conductive fabric comes uninsulated, so when building circuits, it’s susceptible to noise and interference from outside sources, as well as noise generated by the circuit itself. It also gives a lot of opportunity for short circuits.

Another challenge, which is related, is that cond. fabric erodes over time. To make fabric conductive you coat or impregnate it with metal. Sometimes this metal and fiber bond isn’t the strongest, so it wears down and wears off through use. Depending on what metal is used it will also oxidize since it is not properly insulated. There are ways to insulate, this is gone over in the “how to insulate” step.

A good challenge would be to design a project that highlights these negatives, thus turning them into positives to you can work with.

A Bridge Between Demographics

Conductive fabric can be an excellent way to introduce electronics to a wider group of people, such as knitters, weavers, textile artists, fashion designers and a younger age group. It has helped close the gap between fashion and engineering fields, making a new breed of fashion technologists. Designers are finding they want to learn more about programming and electronics and engineers are getting interested in how fabric behaves and best techniques for building with it.

Leah Buechley, the inventor of the LilyPad Arduino, has been a pioneer for teaching girls and women electronics and programming, teaching workshops and writing books that use materials such as conductive fabric. Check out some of her projects and I recommend reading one of her papers on electronics and education.

Step 2: Woven, Stretch or Nonwoven?

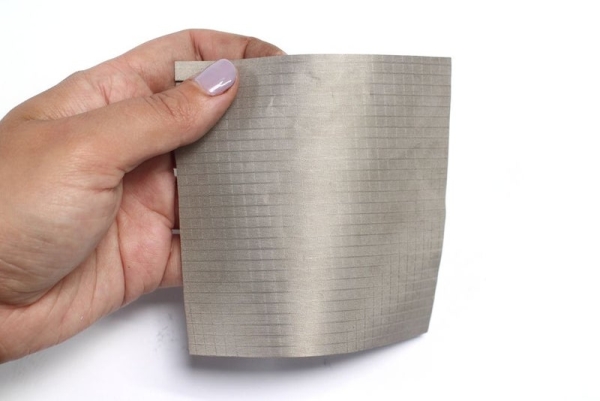

Like other fabrics found in the store, conductive fabric comes in different weights as a woven, knit or nonwoven textile.

Knitted fabrics provide stretch and can drape beautifully. A woven or non-woven will not have any stretch to it, unless it is woven with an elastic fiber, such as Lycra, but this is not commonly found in conductive fabrics.

Different fabric weights are usually described by how many ounces per square yard it weighs. However, this isn’t usually found when shopping for conductive fabric. You can get a sense of weight if the manufacturer lists a fabric as light, medium or heavy weight. However, these terms can mean different weights per square yard depending on whether it’s knit, woven or if the manufacturer knows their stuff. Long story short, ask for swatches or minimum cuts so you can feel and see it for yourself.

When deciding on whether to use a woven, knit or nonwoven conductive fabric, think of what material the conductive fabric will be attached to and what it will be used for. How does it need to drape and move? Will it take a beating and need to be able to take abrasions over time?

Below I’ve listed some pros and cons of the three choices.

Stretch

Knitted fabric that stretches is perfect when you need traces or switches that need to stretch with the substrate it’s attached to. There are light to medium weight fabrics that can be readily found. Some are made using yarns that are blended with natural fibers and coated, which make them soft and very elastic.

Others are knit with thin wire, which makes for a chunkier and less stretchy material. These don’t spring back at all, but can be formed into sculptural shapes. It all depends on what is needed for your project.

Pros

– Perfect if the conductive fabric is being attached to a knit, or a material that needs to expand and contract.

– Knitted stretch fabric can be cut in thin straight ribbons which can be softly bent around curves, which a woven will not be able to do.

– The resistance to current changes once you stretch the fabric, which means that it can be used as a stretch sensor. However, the value reading will be jumpy and unreliable. It will not be the same solid range with each uniform stretch.

Cons

– The change in resistance as it moves is also a con and can be troublesome. This can mess with sensor readings, preventing proper current to get to your LED, motor, etc. Don’t use it if your circuit requires fine tuned current and resistor values. You may still find it useful only as traces that data flows through, or switches and capacitive touch pads.

Woven

There are many choices when it comes to woven conductive fabric. Screen mesh, twills, taffeta and more are available for purchase. Ask for swatches and samples from online resources to see which ones are right for your project.

Pros

– More choices of weight, fiber content and electrical properties available.

– Relatively stable in it’s conductivity and electrical properties.

– Resistance is relatively low in many woven conductive textiles, which is good when using them for power and data lines.

Cons

– Does not stretch or conform as well as knit.

Nonwoven

Nonwoven fabric is a material made from fibers that are bonded together by chemical, mechanical, heat or solvent treatment. Most are laminated with a protective coating, which may need to be removed in order to make contact with the fiber. These can be robust and have an industrial feel.

Pros

– Low resistance can be found in non-woven conductive fabric.

– High resistance nonwovens can be found. The thicker, squishier ones make for great force sensing resistors.

– Some are more breathable than tightly woven fabric.

– Bonding methods can add strength, stability and durability not found in wovens and knits.

Cons

– More difficult to find and not readily available in small quantities.

– Can be stiff and thick, which doesn’t make them optimal for integration into clothing and other items where you want to maintain a soft drape.

Read more: How to Work With Conductive Fabric