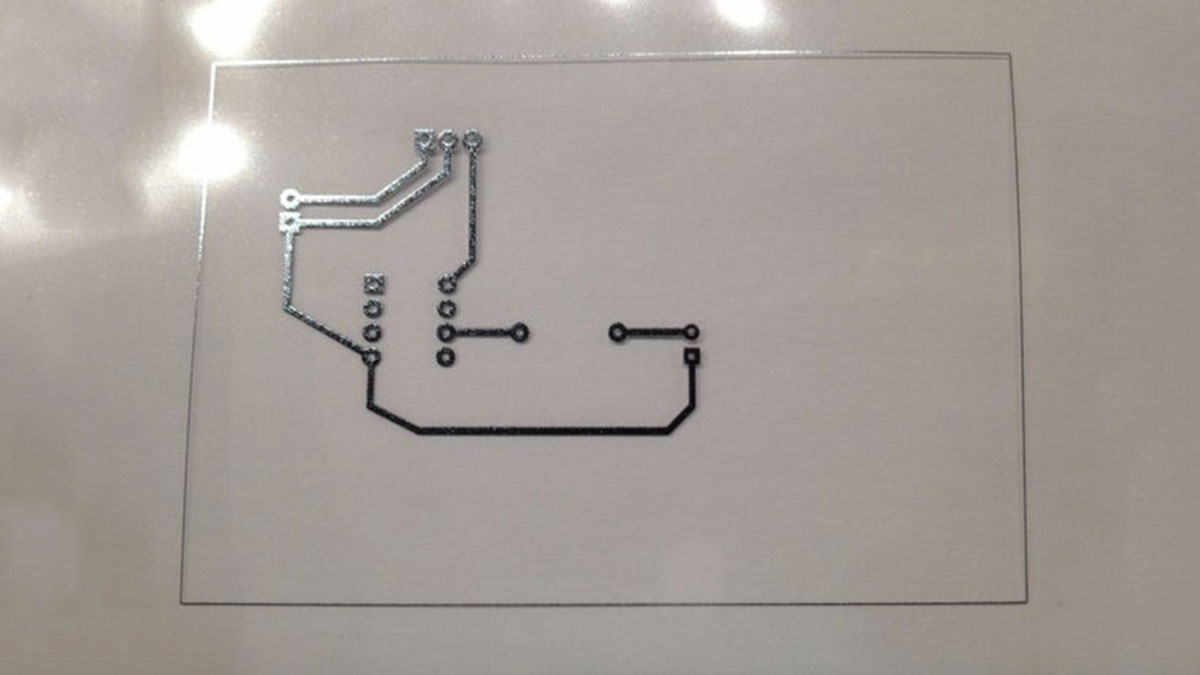

This tutorial will teach you how to modify your average inkjet printer to be able to print electrically conductive circuits. This technology is fairly new but can provide a faster and safer prototyping option for DIY printed circuit boards. This project also acts as an introduction to the larger field of printed electronics.

Step 1: Parts

Needed

- Inkjet Printer ( Brother MFC-J450DW)

- Silver Nanoparticle Ink

- Refillable Ink Cartridges

- Refill Syringes

- Printer Paper

- Quick Drying Transparencies

Optional

- Electrical Tape

- Copper Tape

- Circuit Components

- LED

- 330 Ω Resistor

- ATtiny85

- Dremel

- Power Drill

- Hacksaw

Step 2: What Are Printed Electronics?

Printed electronics can refer to a wide range of techniques that are used to print electrical devices onto a substrate. A substrate is just the technical term for any substance that the printing process takes place on such as paper, glass, cover slips, etc. The techniques for printing electronics are still largely being developed. Some of the main techniques include screen printing[1], rotogravure[2], and inkjet.

Why use printers at all for electronics? Currently there are two main ways of prototyping a circuit, breadboards and printed circuit boards (PCB). They both have their own pros and cons. A breadboard allows for a cheap way to easily connect wires and different components. However the standard layout of a breadboard means that you must conform your parts to fit what you are given.[3] A PCB can be designed to suit the exact needs of the project you are working on. The manufacturing costs of the PCB are its downfall for hobbyists however. It can take weeks to have your order made and shipped to you or the use of potent chemicals if you wish to etch it yourself.[4] The ability to print electronics on demand combines the best qualities of a breadboard and PCB. They are cheap to print, easy to add parts to, and can be revised very quickly. Printing electronics is becoming to the electronics industry what 3D printing has become to the mechanical industry.

Step 3: How Do Inkjet Printers Work?

This project will focus on the inkjet printing method for it is the cheapest and easiest method for hobbyists to get started with. Inkjet printers work mainly by one of two ways. The first being a “Thermal Bubble” where a current is first sent through tiny resistors in the print head. These resistors give off heat and vaporize some of the nearby ink. This vaporization of the ink creates a gas bubble which, as it expands, pushes ink out of the nozzle in the form of tiny droplets. When the bubble eventually pops, a vacuum is created in its absence which refills the nozzle with ink.[5]

The second method is known as a “Piezoelectric” printer. Piezoelectricity is a material property where if a mechanical stress is applied, an electric potential is created. The opposite is also true, if a piezoelectric material is exposed to a change in electric potential energy, then its volume will change.[6] Piezoelectric printers utilize this property by having piezoelectric crystals in the print head’s ink reservoir. When a voltage is applied to these crystals they deform and expel tiny ink droplets out of the nozzle. [5]

Read more: Print Conductive Circuits With an Inkjet Printer