Daniel Eichhorn @ blog.squix.org, shares his experience with some popular PCBA services and documents his finding on his blog. He writes:

Until recently I believed that having PCBs assembled by a professional service is either too costly for small batches or not possible at all. That was until I realized that some PCB manufacturers offer an additional assembly service (PCBA) and that their minimum order quantity (MOQ) is often very low. But which service should you use for future prototypes and market tests?

So I decided to pick a handful of PCBA services and order the same small board from them. Placing the same order with different services should allow me to compare quality, speed and costs between the different services.

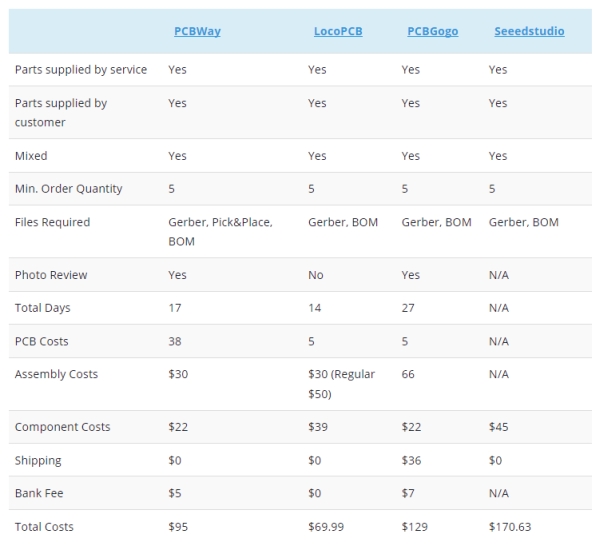

In this post, I’m going to compare four assembly services for printed circuit boards. I got quotes from four services but placed orders with only three of them. One service (Seeedstudio) was simply too expensive for my little experiment.

All four services have a combined PCB/PCBA service. The services first manufacture the printed circuit boards and then they use the boards in a second stage to solder the components. Before you place the order you have to define the job with a couple of form fields. The required documents vary slightly from service to service but basically, you have to deliver Gerber files for the PCB stage and a detailed bill of material (BOM) in CSV or Excel format.

Two services also required a file which describes how to position the components with a pick-and-place machine, sometimes referred to as centroid files. CAD tools often can export this information. Eagle CAD, for instance, can do this with a few simple steps.

In the following paragraphs, I will describe the four services. At the end of this post, I will compare them side by side.

PCBWay

PCBWay offers a rich set of services: regular PCB manufacturing, SMD stencils, flexible PCBs, advanced PCBs as well ass PCB assembly.

For the initial price quote, you have to provide 4 numbers: quantity of boards for assembly, number of unique parts on one board, number of surface-mounted parts and number of through-hole parts.

You can then choose from three options how the components will be sourced: either PCBWay sources the parts for you or you send the parts to them. Or you provide some of them and PCBWay sources the rest.

For the initial quote, you also need to provide the size of the PCB and a couple of other aspects for PCB manufacturing. To get the final quote you need to have the Gerber files, a bill of materials (BOM) and a CSV file containing coordinates for the pick-and-place machine. The BOM is in Excel format. It’s best to download their Excel template and to provide the required information.

It took only a couple of hours until I got a reply from a PCBWay sales rep. The email contained an updated Excel file with costs per part. The sales rep asked me to check the BOM to make sure that they will source the correct components.

Since everything seemed to be as planned I paid. PCBWay has a wide range of payment options: PayPal, Credit Cards, Western Union and even Bank Transfer.

Production Phase

What I really liked about the PCBWay platform was the possibility to closely track the progress of the PCB order. The assembly doesn’t quite provide this level of information. I would assume that the IT system for PCB production is a lot more mature and integrated than the one for assembly. For my small quantity they probably even soldered by hand.

Read more: PCBA SERVICE REVIEW – COMPARING PCBWAY VS LOCOPCB VS PCBGOGO VS SEEEDSTUDIO