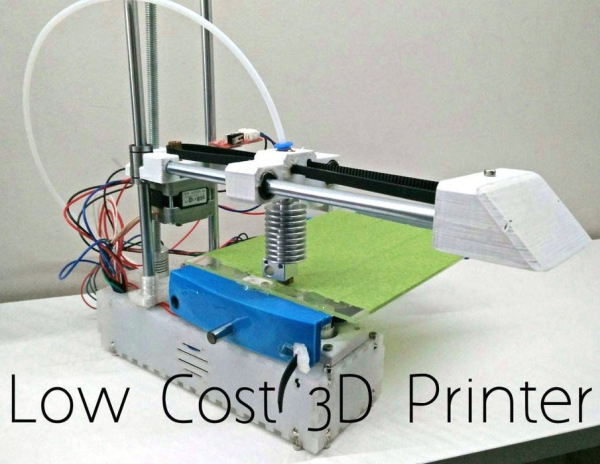

Hello everyone! In this instructable I will show you how to make a low cost 3d printer that I designed! It should cost around $150 US dollars or $175 Canadian dollars, if you buy from the links provided in this project (parts are from Aliexpress). You can also buy locally but it will cost more (about $300- $400 instead of $150).

The print bed size is 5.5″x6″x6″.

Update: Version 3.0 will be posted on Feb 8 2016 at 3:00 (PT)

You WILL need to have at least some knowledge in 3d printing to complete this project.

***Please vote for this Instructable in the CNC challenge (upper right corner) ! I’m 13 and I designed and built this myself so please, if you like this instructable favourite, vote and comment. It encouages me to keep doing what I do.***

Step 1: Parts and Tools

Parts:

GT2 pulley x2: http://tinyurl.com/qc4m6ez

GT2 Belt (about 2m): http://tinyurl.com/nr6wn25

USB type b to type b extender x1: http://tinyurl.com/ohcmybf

DC power socket x1: http://tinyurl.com/nwe8lv5

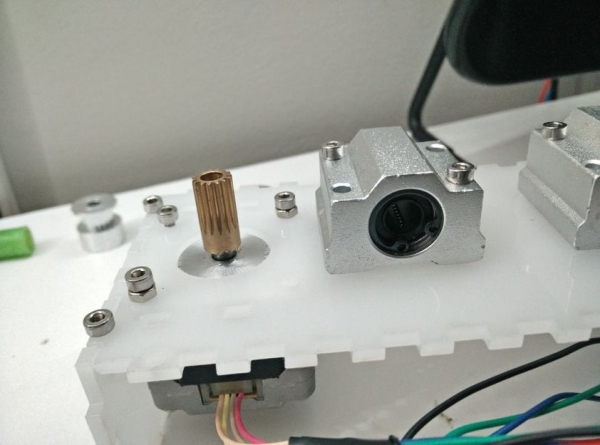

LM8UU Linear Bearing x4: http://tinyurl.com/n98ehwv

Acrylic x2 8″x12″ (You can also buy it from a local plastics shop and it is about the same price as aliexpress): http://tinyurl.com/k4bzjge

30mm Fan x2: http://tinyurl.com/nqxgg8d

3d printer wiring pack: http://tinyurl.com/o8mont4

Direct Drive gear x1: http://tinyurl.com/on5sr2p

608 bearings x1 lot of 5: http://tinyurl.com/kqo2lpg

M3 8mm screws x1 lot of 50: http://tinyurl.com/kz48fcp

5mm to 8mm coupler x1: http://tinyurl.com/pmwtn8r

SC8UU linear bearing x2: http://tinyurl.com/pp9jquw

1m PTFE tube (bowden tube) x1: http://tinyurl.com/lowr6uq

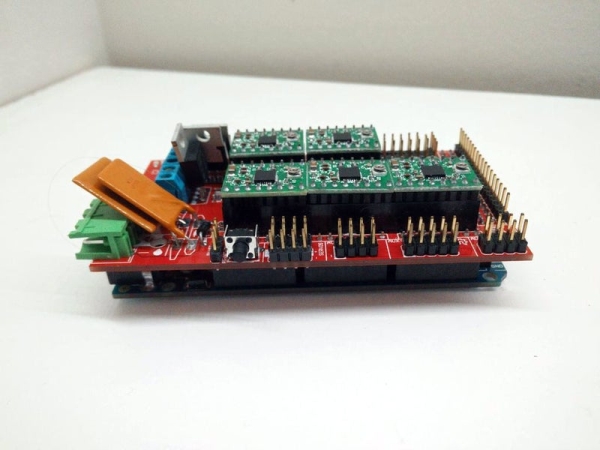

Arduino Mega and RAMPS board kit x1: http://tinyurl.com/lzozwlw

Endstops x3: http://tinyurl.com/q47m5cq

Nema 17 motors x4: http://tinyurl.com/njwgj4l

All Metal hotend: http://tinyurl.com/l5b9xm2 you can also use a ceramic one instead.

Smooth Rods: 1272T38 Mcmaster Carr part #

Threaded Rod: Home depot 5/16 inch threaded rod and a nut that screws onto the rod

Tools:

Laser Cutter

3D Printer and filament or buy the parts from 3dhubs.com

Files

Soldering Iron and Solder

Computer with Arduino IDE, Pronterface, Slicer software

Step 2: Laser Cut and 3D Print Parts

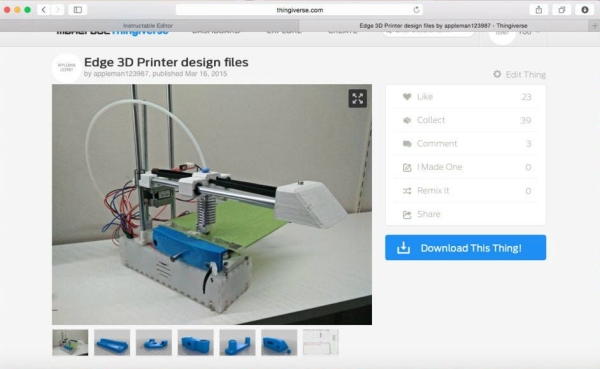

Go to this thingiverse link to download the files: http://www.thingiverse.com/thing:725640

Extruder: http://www.thingiverse.com/thing:215010

Step 3: Mount Motors to Acrylic Parts

Using the m3 10mm screws mount the nema 17 stepper motor to the main acrylic piece. This is the piece that has the most mounting holes. Do this for both the both the x and z motors.

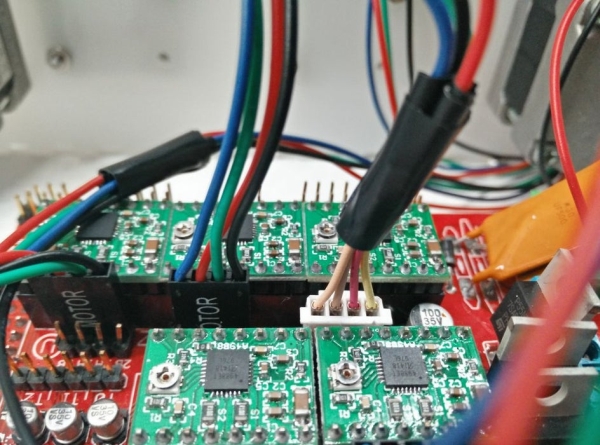

Step 4: Wire Motors to the RAMPS Board

Plug the motor cable into the connector board. On the board, there are headers that you connect the cable to. Don’t worry about polarity: this won’t affect the motor, it will just spin in reverse which you can invert in the firmware.

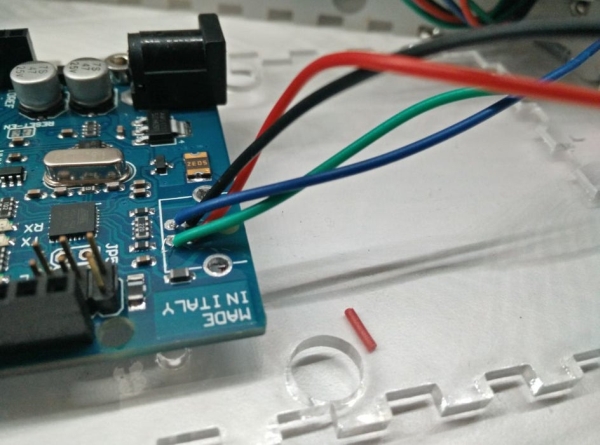

Step 5: Extend Arduino’s USB Connector

Extend arduino’s USB connector by desoldering the type b connector and just adding wires to each of the pins bringing the wires to the connector. It sounds complicated, but it is really simple.

Read more: Edge 3D Printer 1.0 – an Affordable Open Source 3D Printer!