The objective of this project is to create a version of Arduino Mega 2560 board that has lower component count and smaller board size.

Personally to be used for robotics projects that require ATmega2560’s 256 KB flash and digital/analog pins, where the size, weight, and USB port location of the original design is not ideal.

References:

- Mr. Nick Gammon’s How to make an Arduino-compatible minimal board

- TSJWang’s DIY Arduino Mega 2560 or 1280

Electronics/PCB knowledge provided by:

Step 1: Prototype

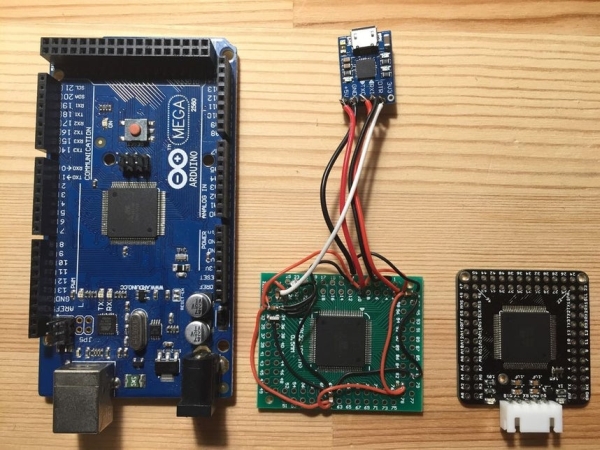

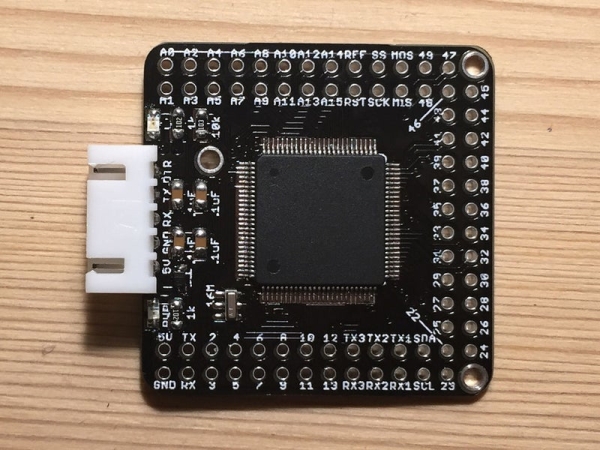

A prototype board was made as proof of concept, the components, placements, and connections are:

- ATmega2560 chip from an Arduino Mega2560 clone (functional chip and bootloader) removed with a hot-air gun, soldered on to a TQFP100 breakout PCB.

- Connect all VCC/AVCC (chip pins 10, 31, 61, 80, 100) together and GND (chip pins 11, 32, 62, 81, 99) together.

- 0.1uF bypass capacitor x 3, connected in parallel to 3 of the VCC/AVCC and GND pairs (chip pins {31,32}, {61,62}, {99,100}).

- 10k pull-up resistor x 1 connected between RESET (chip pin 30) and VCC/AVCC.

- LED x 1 and 1k current limiting resistor x 1 connected between D/13 (chip pin 26) and GND, this is same as the Arduino Mega “L” LED, to be us as indicator to test prototype.

- 16MHz ceramic resonator connected between chip pins 33 and 34, with resonator’s ground pin connected to chip’s GND.

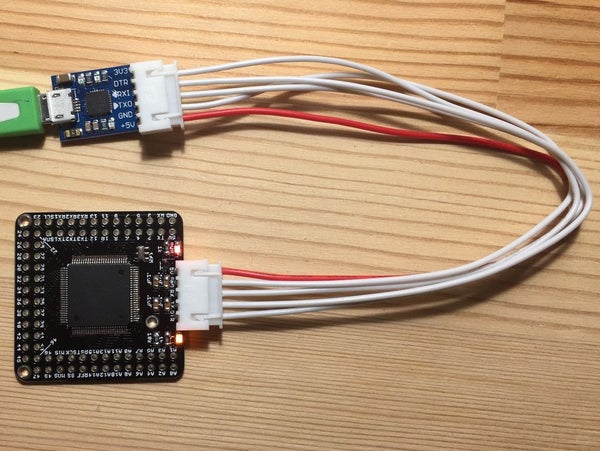

- CP2102 USB to UART TTL Module (one that has a DTR pin), with the connections:

- 0.1uF capacitor x 1 between module’s DTR pin and RESET (chip pin 30).

- Module’s RX to D1/TX (chip pin 3).

- Module’s TX to D0/RX (chip pin 2).

- Module’s 5V to chip’s VCC/AVCC.

- Module’s GND to chip’s GND.

After the driver for CP2102 was installed, a few sample Arduino sketches such as “Blink” and “Fade” were uploaded to make sure the chip was still functioning before designing the board in Eagle PCB.

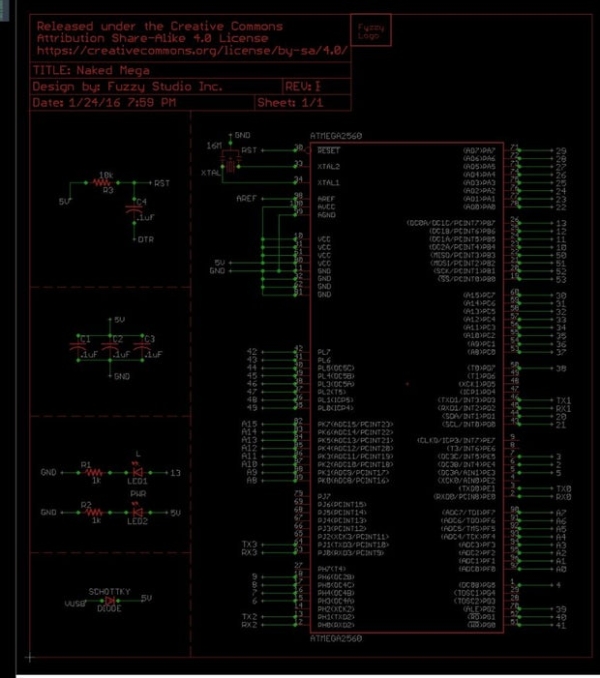

Step 2: EAGLE PCB: Revision I

Additional components compared to the prototype board:

- LED x 1 and 1k current limiting resistor x 1 between chip’s AVCC/VCC and GND as power indicator.

- Schottky diode between CP2102 module 5V input pin and onboard 5V pin, to prevent reverse-current going to computer’s USB port when CP2102 module and an external 5V DC power source are connected at the same time.

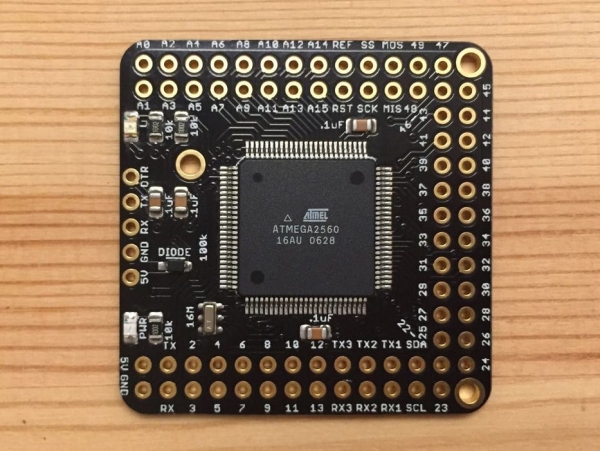

Specifications/features of the board layout:

- Total component count on board is 12.

- Board dimension is 38.1mm x 38.1mm.

- Connector pins to match CP2102 module.

- All digital pins and analog pins arranged in sequential order.

- Mounting holes.

- 4-layer PCB (failed attempt to route the traces in 2-layer).

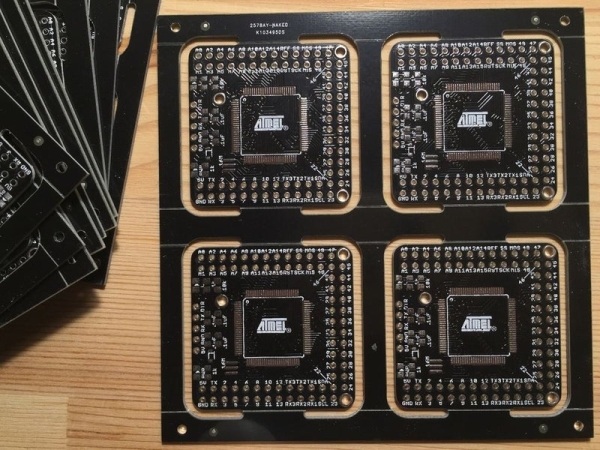

Step 3: PCB Production: Revision I

PCB’s were made by a manufacture found on China’s www.taobao.com; the cost for 4-layer PCB was 300RMB (45USD) excluding shipping for 10 pieces of 10cm x 10cm board (total of 48 “Naked Mega” produced, with panelizing and extras boards giving by the manufacture), production time was 6 days.

The leaded HASL process was selected for surface finish, this finish is not very flat, thus silkscreen (text and logo…etc.) wasn’t pretty; next revision will probably try Electroless Nickel Immersion Gold (ENIG) as the surface finish, cost would be 400RMB (60USD) for the same order.

Step 4: Solder Components: Revision I

Step 5: Upload Bootloader

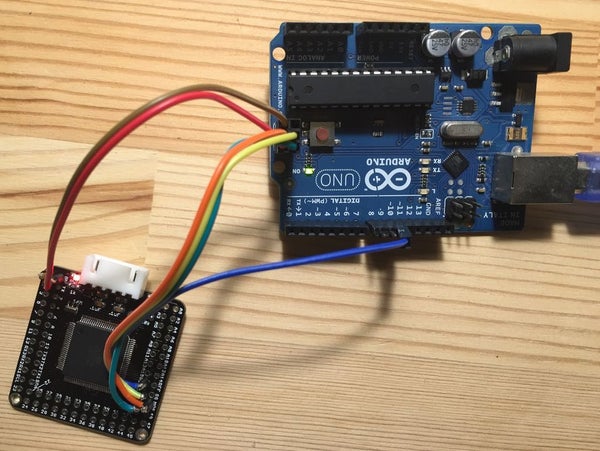

Used an Arduino Uno to upload bootloader onto the ATmega2560 chip, connections:

- Arduino UNO SS (D10) -> Naked Mega Reset/RST pin.

- Arduino UNO MOSI (D11) -> Naked Mega MOSI (D51).

- Arduino UNO MISO (D12) -> Naked Mega MISO (D50).

- Arduino UNO SCK (D13) -> Naked Mega SCK (D52).

- Arduino UNO VCC/5V -> Naked Mega 5V.

- Arduino UNO GND -> Naked Mega GND.

Downloaded Mr. Nick Gammon’s Atmega_Board_Programmer, and upload bootlaoder to chip using Serial Monitor of Arduino IDE according to instructions.

Step 6: Upload Sketch

If the driver for CP2102 was installed, when connected the Naked Mega can be programmed like an original Arduino Mega 2560.

Read more: DIY Bare Minimum Arduino Mega 2560