Summary of CT sensors – Interfacing with an Arduino

The article details how to connect a CT (Current Transformer) sensor like the YHDC SCT-013-000 to an Arduino by converting the sensor's current output into a suitable voltage signal for the Arduino's analog input. It explains calculating the burden resistor to convert current to voltage, adding a DC bias voltage for the Arduino's single-ended ADC input, and provides examples for different hardware, including emonTx and emonPi. The guide also discusses resistor value selection, power considerations, and includes an Arduino sketch for measuring RMS current.

Parts used in the CT Sensor to Arduino Interface Project:

- YHDC SCT-013-000 CT Sensor

- Burden resistor (e.g., 33 Ω ±1%)

- Voltage divider resistors R1 & R2 (e.g., 10 kΩ or 470 kΩ)

- Capacitor C1 (10 μF)

- Arduino board (5 V or 3.3 V)

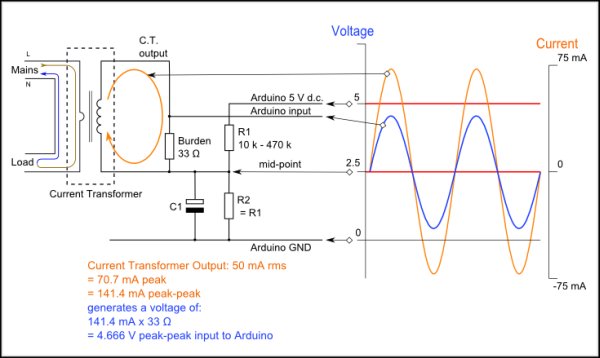

To connect a CT sensor to an Arduino, you need to adjust the CT sensor’s output signal to match the Arduino’s analog input requirements: a positive voltage ranging from 0V to the ADC reference voltage.

Note:

This page shows an example of an Arduino board running at 5 V and an EmonTx running at 3.3 V. Make sure to use the correct supply and bias voltages in your calculations that correspond to your setup.

This can be done by using the following circuit, which consists of two main parts:

- The CT sensor and burden resistor

- The biasing voltage divider (R1 & R2)

Calculating a suitable burden resistor size

In the situation of a CT sensor such as the YHDC SCT-013-000 which produces current, a burden resistor is needed to change the current signal into a voltage signal. If the CT provides a voltage output, you can skip this step and forgo the burden resistor as it is already integrated into the CT.

1) Choose the current range you want to measure

The YHDC SCT-013-000 CT has a current range of 0 to 100 A so for this example let’s choose 100 A as our maximum current.

2) Convert maximum RMS current to peak-current by multiplying by √2.

Primary peak-current = RMS current × √2 = 100 A × 1.414 = 141.4A

3) Divide the peak-current by the number of turns in the CT to give the peak-current in the secondary coil.

The YHDC SCT-013-000 CT has 2000 turns and so the secondary peak current will be:

Secondary peak-current = Primary peak-current / no. of turns = 141.4 A / 2000 = 0.0707A

4) To maximise measurement resolution the voltage over the burden resistor at peak-current should be the Arduino analog reference voltage (AREF) divided by 2

If you’re using an Arduino running at 5V: AREF / 2 will be 5 V / 2 = 2.5 V and so the ideal burden resistance will be

Ideal burden resistance = (AREF/2) / Secondary peak-current = 2.5 V / 0.0707 A = 35.4 Ω

35 Ω is a rare resistor value, so we can choose between 39 Ω or 33 Ω. Choose the lower value right away to avoid the maximum load current causing the voltage to go above AREF. We recommend selecting a 33 Ω resistor with a tolerance of ±1%. Utilizing a combination of two resistors in series may occasionally result in a burden value that is closer to the ideal. The precision lessens the more the value strays from the perfect. In this situation, the peak current will result in an analog output of 4.7V (equal to 3822 when converted using a 12bit ADC).

Below are the same calculations from earlier presented in a more concise manner.

Burden Resistor (ohms) = (AREF * CT TURNS) / (2√2 * max primary current)

Burden resistor sizing for OpenEnergyMonitor energy monitoring hardware.

emonTx V3 (see guide)

The emonTx V3 uses a 3.3V regulator, so it’s VCC and therefore AREF, will always be 3.3V regardless of battery voltage. The standard emonTx V3 uses 22Ω burden resistors for CT 1, 2 and 3, and a 120Ω resistor for CT4, the high sensitivity channel. See the emonTx V3 technical wiki at: https://wiki.openenergymonitor.org/index.php?title=EmonTx_V3#Burden_Resistor_Calculations.

emonPi (see guide)

The EmonPi has two CT channels both with 22Ω burden resistors.

emonTx V2

If you’re using a battery powered emonTx V2, AREF will start at 3.3 V and slowly decrease as the battery voltage drops to 2.7 V. The ideal burden resistance for the minimum voltage would therefore be:

Ideal burden resistance = (AREF/2) / Secondary peak-current = 1.35V / 0.0707A = 19.1 Ω

19 Ω is not a common value. We have a choice of 18 or 22 Ω. We recommend using an 18 Ω ±1% burden.

Tool for calculating burden resistor size, CT turns and max Irms (thanks to Tyler Adkisson for building and sharing this).

(Note: this tool does not take into account maximum CT power output. Saturation and distortion will occur if the maximum output is exceeded. Nor does it take into account component tolerances, so the burden resistor value should be decreased by a few (~5) percent allow some “headroom.” There is more info about component tolerances at: ACAC Component tolerances.)

Adding a DC Bias

If you connect a single wire on the CT to the ground and measure the voltage on the other wire in relation to the ground, you will observe fluctuations in voltage transitioning from positive to negative in relation to the ground. However, the Arduino analog inputs require a positive voltage. Connecting the CT lead to a source at half the supply voltage rather than ground will cause the CT output voltage to fluctuate above and below 2.5 V while remaining positive.

R1 & R2 resistors in the circuit diagram serve as a voltage divider to provide a 2.5 V input (with 1.65 V allocated for the emonTx). Capacitor C1, having a reactance of just a few hundred ohms, permits the alternating current to flow around the resistor by providing a path with low impedance. A capacitance of 10 μF is suitable.

Choosing a suitable value for resistors R1 & R2

Increased resistance leads to decreased standby power usage.

Mains powered monitors are equipped with 10 kΩ resistors. The emonTx utilizes 470 kΩ resistors to ensure low power usage, as it is designed to operate on batteries for an extended period of time.

Arduino Sketch

To use the above circuit to measure RMS current, with an assumed fixed RMS voltage (e.g. 240V) to indicate approximate apparent power, use this Arduino sketch: Arduino sketch – current only

CT Sensors

In this Chapter:

For more detail: CT sensors – Interfacing with an Arduino