Welcome to our new blog series based on our experience with PCB manufacture and assembly, courtesy of our engineers. Over the years, we’ve seen our fair share of blunders and subsequent losses over the course of the hardware development process. With a bit of understanding, forward-thinking and patience many of these problems can easily be avoided. This series aims to tackle the understanding part with a look at some real-life examples we’ve encountered.

Today we are going to share with you a real case study involving a Seeed Fusion PCBA customer’s design. At the time of placing the order, the customer requested the default HASL surface finish, but listed in their Bill of Materials was a 0.4mm BGA. It’s a small BGA with only four balls in the array, but the combination of 0.4mm pitch BGA and HASL surface finish should ring alarm bells, and here’s why:

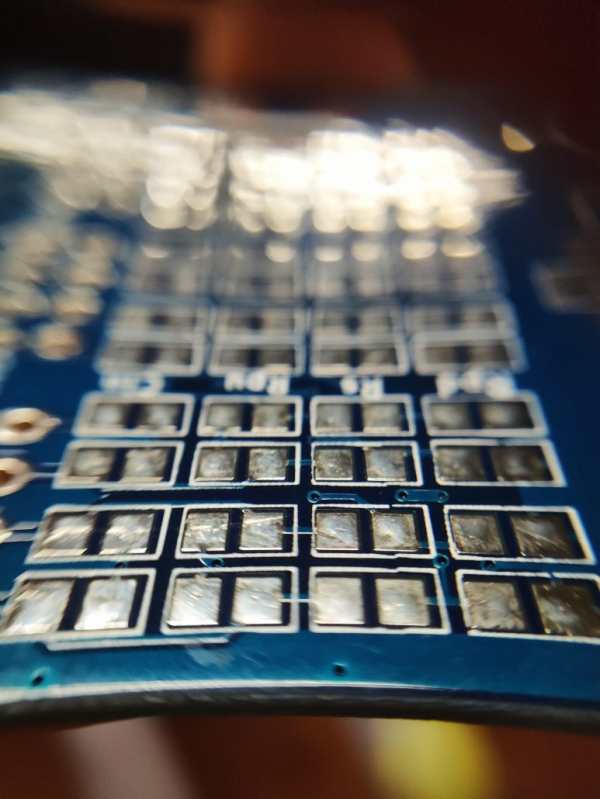

The HASL surface finish is essentially a coating of solder that protects the copper pads from oxidation. As its name suggests, the Hot Air Solder Level technique has the boards dipped in a bath of molten solder and then uses a hot air blade to remove as much of the excess solder as possible. But as anyone who has soldered a joint before knows, solder behaves very much like water in its molten state, in that it tends to form droplets and welcomingly coalesces with other liquified solder droplets. It is the high surface tension that results in an uneven surface and rounded edges, a meniscus, instead of covering the surface evenly.

Compare these images of HASL finish on the left and ENIG on the right:

For larger pads and leads, the uneven surface, or poor coplanarity in technical terms, barely has any effect on the solderability of the pads, but as component leads and pads get smaller and closer together, it becomes increasingly more serious and can have a major impact on yield.

Despite this, the customer insisted on proceeding with the HASL finish and after an initial test run of 10 pieces, the BGA joints exhibited poor strength, reliability and showed signs of insufficient wetting, if at all on some pads. Analysis of the pads showed that 30% of the pads (that’s at least one pad per BGA) were of a different size or shape, resulting in poor gasketing during solder paste application which subsequently caused differences in solder ball size.

Furthermore, the quality of the HASL process and the make-up of the solder alloy affect planarity, so there are no set limits as to what size pads HASL can manage. But as a general precaution, fine pitch components with a pitch less than 0.5mm and 0.5mm pitch BGAs should not be using HASL. To be safe, you may want to consider raising the limit to even 0.8mm pitch pads BGAs if you are not familiar with the quality of the HASL process.

At Seeed, our go-to solution to this problem is to switch to the ENIG surface finish, Electroless Nickel Immersion Gold. This technique uses a chemical process to first plate the copper surfaces in nickel and then with a thin layer of pure gold on top. While it is more expensive than HASL (it’s really gold), the nature of the plating process allows it to offer superior surface planarity.

Read more: CHOOSING A SURFACE FINISH FOR FINE-PITCH COMPONENTS