Summary of Automatic Arduino Pet Feeder – 3D Printed (With Stepper Motor)

This project describes an automatic 3D printed pet feeder controlled by an Arduino UNO. The user sets two feeding times via a 4x4 keypad; at these times, a NEMA17 stepper motor activates to dispense food. The system includes an RTC DS3231 for accurate timing, an LCD display for time and feeding status, and a step-down module to regulate power. The feeder parts are 3D printed and assembled using M3 bolts and nuts.

Parts used in the Automatic 3D Printed Pet Feeder:

- NEMA17 Stepper Motor (42HB34F08AB)

- Stepper Motor Driver A4988

- Arduino UNO

- 4x4 Arduino Keypad

- RTC DS3231 Real Time Clock Module

- 16x2 LCD Display

- LM2596S DC/DC Step Down Module (12V to 5V)

- 12V Power Supply

- 3D Printed Parts

- M3 Bolts and Nuts

- Connecting Wires

Hi guys,

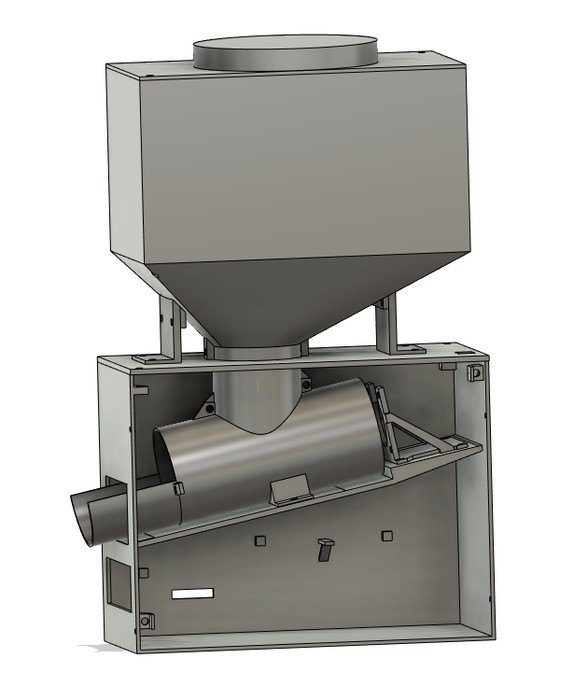

I made an automatic 3D Printed Pet Feeder (or just dispenser, but I use it to feed my dog). I 3D modelled all that project. U can print it by yourself. All parts are down there.

Basically how it works, is u type in two Feeding Times, for example 8:30 and 17:30, then when time is right stepper motor enables and feeds your little pet.

Electric Components:

- Stepper Motor NEMA17 – 42HB34F08AB

- Stepper Motor Driver A4988

- Arduino UNO

- Arduino Keypad 4×4

- RTC DS3231 Clock

- LCD Display 16×2

- Step Down Module (I used LM2596S DC/DC) 12V to 5V

- 12V Power Supply

- a lot of wires

Step 1: Printing All Parts

Printing all the parts took me about 5 days. To assemble everything together I used 3mm bolts (m3) and 3mm nuts.

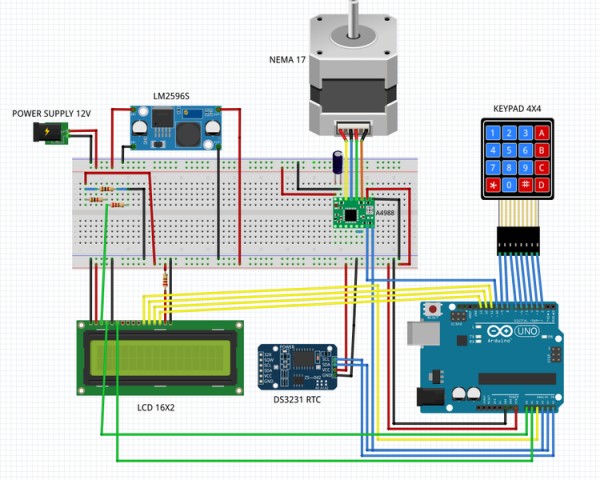

Step 2: Electronics

Wire everything like in the circuit. If your LCD screen is too dark or too bright try different values of resistors or play with the voltage regulator.

Step 3: Arduino Code

Arduino Code includes additional libraries: DS3231 RTC, Arduino Keypad 4×4

When you press ‘A’ – Program asks for first feed time and waits untill you type in HH:MM:SS

When you press ‘B’ – Program asks for second feed time and waits untill you type in HH:MM:SS

When you press ‘C’ – Stepper Motor runs for one cycle (one feed)

When you press ‘D’ – LCD displays current Date

LCD displays normally current Time and hour and minutes of first and second feed time.

All functions are described in code:

#include <DS3231.h>

#include <LiquidCrystal.h>

#include <Keypad.h>

const byte ROWS = 4;

const byte COLS = 4;

const int stepPin = 10;

const int dirPin = A3;

char keys[ROWS][COLS] = {

{'1','2','3','A'},

{'4','5','6','B'},

{'7','8','9','C'},

{'*','0','#','D'}

};

byte rowPins[ROWS] = { 2, 3, 4, 5 };

byte colPins[COLS] = { 6, 7, 8, 9 };

Keypad keypad = Keypad( makeKeymap(keys), rowPins, colPins, ROWS, COLS );

DS3231 rtc(A4, A5);

LiquidCrystal lcd(A0, A1, A2, 11, 12, 13); // (rs, enable, d4, d5, d6, d7)

int feed_time = 2000; //define how fast stepper motor works

int feed_length = 600; //define how much steps should your motor do (mine does 200 for full spin)

String feed1;

String feed2;

char key[8];

int j = 0;

char button;

void setup() {

rtc.begin();

lcd.begin(16,2);

Serial.begin(9600);

pinMode(A0, OUTPUT);

pinMode(A1, OUTPUT);

pinMode(A2, OUTPUT);

pinMode(stepPin,OUTPUT);

pinMode(dirPin,OUTPUT);

}

void loop() {

lcd.setCursor(0,0);

lcd.print("Time: ");

lcd.print(rtc.getTimeStr());

lcd.setCursor(0,1);

//lcd.print("Date: "); //Date to display

//lcd.print(rtc.getDateStr());

lcd.print("1)");

lcd.print(feed1);

lcd.setCursor(7,1);

lcd.print(" 2)");

lcd.print(feed2);

lcd.setCursor(15,1);

lcd.print(" ");

button = keypad.getKey();

if(button == 'A'){

lcd.clear();

lcd.setCursor(0,0);

lcd.print("HH:MM:SS 1st");

delay(500);

j = 0;

lcd.setCursor(j,1);

key[0] = keypad.waitForKey();

lcd.print(key[0]);j++;

lcd.setCursor(j,1);

key[1] = keypad.waitForKey();

lcd.print(key[1]);j++;

lcd.setCursor(j,1);

key[2] = ':';

lcd.print(key[2]);j++;

lcd.setCursor(j,1);

key[3] = keypad.waitForKey();

lcd.print(key[3]);j++;

lcd.setCursor(j,1);

key[4] = keypad.waitForKey();

lcd.print(key[4]);j++;

lcd.setCursor(j,1);

key[5] = ':';

lcd.print(key[5]);j++;

lcd.setCursor(j,1);

key[6] = keypad.waitForKey();

lcd.print(key[6]);j++;

lcd.setCursor(j,1);

key[7] = keypad.waitForKey();

lcd.print(key[7]);

key[8] = '\0';

feed1 = String(key);

delay(1000);

lcd.clear();

}

if(button == 'B'){

lcd.clear();

lcd.setCursor(0,0);

lcd.print("HH:MM:SS 2nd");

delay(500);

j = 0;

lcd.setCursor(j,1);

key[0] = keypad.waitForKey();

lcd.print(key[0]);j++;

lcd.setCursor(j,1);

key[1] = keypad.waitForKey();

lcd.print(key[1]);j++;

lcd.setCursor(j,1);

key[2] = ':';

lcd.print(key[2]);j++;

lcd.setCursor(j,1);

key[3] = keypad.waitForKey();

lcd.print(key[3]);j++;

lcd.setCursor(j,1);

key[4] = keypad.waitForKey();

lcd.print(key[4]);j++;

lcd.setCursor(j,1);

key[5] = ':';

lcd.print(key[5]);j++;

lcd.setCursor(j,1);

key[6] = keypad.waitForKey();

lcd.print(key[6]);j++;

lcd.setCursor(j,1);

key[7] = keypad.waitForKey();

lcd.print(key[7]);

key[8] = '\0';

feed2 = String(key);

delay(1000);

lcd.clear();

}

if(button == 'D'){

lcd.clear();

lcd.setCursor(0,0);

lcd.print("Time: ");

lcd.print(rtc.getTimeStr());

lcd.setCursor(0,1);

lcd.print("Date: "); //Date to display

lcd.print(rtc.getDateStr());

delay(5000);

lcd.clear();

}

if(button == 'C'){

digitalWrite(dirPin,HIGH); // Enables the motor to move in a particular direction

for(int x = 0; x < feed_length; x++) { // Makes 200 pulses for making one full cycle rotation

digitalWrite(stepPin,HIGH);

delayMicroseconds(feed_time);

digitalWrite(stepPin,LOW);

delayMicroseconds(feed_time);

}

delay(1000);

}

if (feed1==rtc.getTimeStr())

{

digitalWrite(dirPin,HIGH); // Enables the motor to move in a particular direction

for(int x = 0; x < feed_length; x++) { // Makes 200 pulses for making one full cycle rotation

digitalWrite(stepPin,HIGH);

delayMicroseconds(feed_time);

digitalWrite(stepPin,LOW);

delayMicroseconds(feed_time);

}

delay(1000);

}

if (feed2==rtc.getTimeStr())

{

digitalWrite(dirPin,HIGH); // Enables the motor to move in a particular direction

for(int x = 0; x < feed_length; x++) { // Makes 200 pulses for making one full cycle rotation

digitalWrite(stepPin,HIGH);

delayMicroseconds(feed_time);

digitalWrite(stepPin,LOW);

delayMicroseconds(feed_time);

}

delay(1000);

}

} Source: Automatic Arduino Pet Feeder – 3D Printed (With Stepper Motor)