Summary of WIRE CUTTING MACHINE

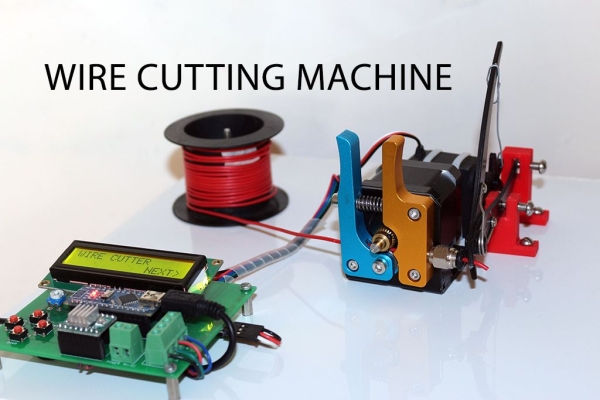

The article describes an Automatic Wire Cutting Machine controlled by an Arduino Nano. The machine allows users to input wire length and quantity via push buttons, displaying real-time data on a 16x2 LCD. The Arduino processes these inputs to control a stepper motor for wire feeding and a servo motor for cutting the wire. The project involves assembling components on an acrylic base, designing a custom PCB, and programming the Arduino. The machine operates with a 12V power supply for the stepper motor and USB power for the Arduino and servo, enabling precise wire cutting for specified lengths and quantities.

Parts used in the Automatic Wire Cutting Machine:

- Arduino Nano

- Stepper Motor

- Stepper Motor Driver (A4988)

- 16 x 2 LCD Display

- Servo Motor

- Cutter

- PCB Terminal

- Push Buttons

- 3mm Thick White Acrylic Sheet (for base)

- Female Header Pins (for mounting components on PCB)

Hello friends

I have made a Automatic wire cutting machine using Arduino nano controller board.

Basically there are 3 process level of this machine like

1) first process is Input

Input like wire length and wire quantity provided by pressing push button also the real time data can read on 16 X 2 LCD

2) Processing

all the inputs were processed by arduino nano and give command to stepper motor to feed required length of wire and instruct to servo to make cut of required quantity.

3) Output

Stepper motor, servo motor & cutter are the final output component

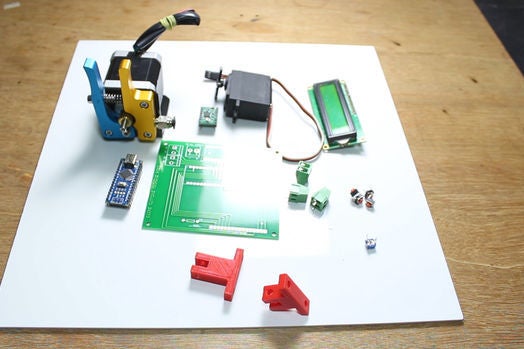

Step 1: Material Required

Followings are the material required

Arduino nano :- http://amzn.to/2Dcp2bK

Stepper motor :- http://amzn.to/2Dg6wycstepper

Motor driver :- http://amzn.to/2Dg6wycstepper

16 x 2 LCD :- http://amzn.to/2Db9LYA

Servo motor :- http://amzn.to/2r5oejj

Cutter :- http://amzn.to/2D9X6oZ

PCB terminal :- http://amzn.to/2r8uCq7

Push buttons :- http://amzn.to/2D9XbsN

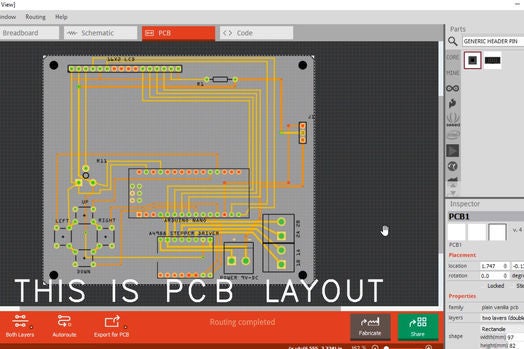

Step 2: PCB Design

I have prepare PCB layout in fritzing software then Designe a PCB and export its gerber file

This gerber file uploaded to Jlcpcb.com to order the PCB as soon as you recived PCB you need to solder some female header pins to mount arduino nano, LCD display & A4988 driver also solder the PCB terminal to connect power supply to the PCB and to connect stepper motor to PCB here I attached the editable PLC layout file so if you can do any modification required.

https://drive.google.com/file/d/1iC4AMHDUVlfjNlICE…

Step 3: Procedure

So as soon as all the components are available you can start assembly the machine.

For the base of the machine I used 3MM thick white acrylic sheet

I drill some hole on sheet to mount PCB, Stepper motor with extruder set, cutter & servo motor for better idea please watch video it will give a idea how to mount those components on sheet all the components are tightly mount on the sheet now we can move to program our arduino

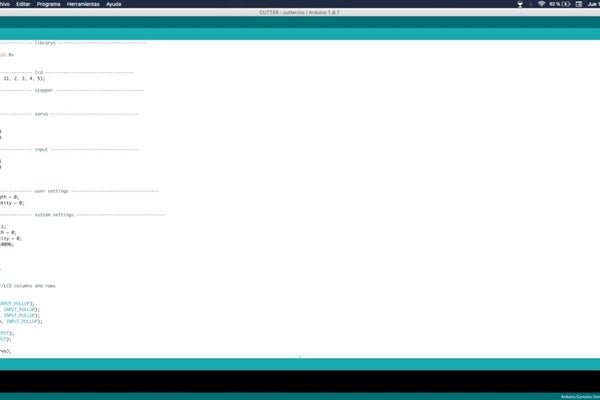

Step 4: Arduino Program

Upload the code to the arduino

Now connect the 12V DC at terminal of PCB this is for stepper motor and connect USB to arduino nano this will feed power to arduino itself and servo motor now machine is ready to perform you need to press those push buttons to navigate between screen and to select desire data hope you will like my this project

Source: WIRE CUTTING MACHINE