One year ago some personal problems forced us to interrupt our hobby work, but fortunately we are back and we found some time to develop new ideas, projects and writings.

At this moment we are starting the first feasibily testing of an innovative 3D printing method that we’ve named Resin Deposition Modelling (RDM). Personally I also hope it will be useful for 3D printing electronics using conductive resins.

As you probably know, actually there are three main 3D printing methods: Fuse Deposition Modelling, Selective Laser Sintering (SLS) and

Stereo Lithography (SLA).

Fuse Deposition Modelling, which is the most widespread at hobby level, is based on melting and depositing thin layers of plastic filament, usually PLA or ABS. Basically the molten plastic is ejected through a hot-end with a nozzle. Second method, Selective Laser Sintering (SLS), consists of melting a metal or a polymer powder using a powerful laser. Finally, Stereo Lithography method uses a light source to cure fine layers of UV sensitive resin. This method has two variants: Laser Stereolithography (SLL) and Digital Light Processing (DLP). The first one uses an ultraviolet laser+galvos to cure the resin and the second a slide projector.

The method that we are presenting today is a hybrid between Laser Stereolithography and the FDM method and we named it Resin Deposition Modelling (RDM). The term perhaps is not the most correct but it is short and differentiates itself from the rest of methods. The correct term could be UV Resin Laser Deposition Modelling, but is too long and Laser Deposition Modelling has been already used.

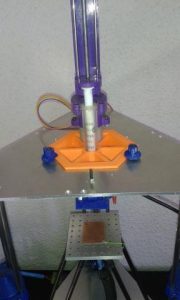

This innovative method consists in depositing material (UV curable resin) by means of a dispenser and a needle and immediately cure it using a 100mw/405nm laser diode beam.

Basically, we developed a toolhead for TwinTeeth that incorporates a rotating turret implementing a new axis – the R axis. This axis guides the laser beam tangentially to the dispensing needle, in such a way, that the beam is always following the path of the needle and hopefully curing the resin, just when it is out of the orifice.

We are using a 0.25mm ID neddle but it could be thinner, so we hope to have better accuracy than the FDM method and being able to print layers of less than 0.1mm, since the resin has a low viscosity index. We are using some DLP resin which Robofactory friends donated us. Thanks very much Andrea for the resin. Robotfactory is a proffesional DLP printer company site in north Italy.

We also would like to thanks Mecaduino’s friends who helps us machining some custom pieces.

At the moment the toolhead is a little slower when printing fillings than the FDM method because it has to move the turret 180 degrees when changing direction, but fortunately this is easy to solve.

Read more: Making PCB Vias using conductive ink