What is the PCB?

As far as Printed circuit board is concerned, it is a board which is used in electronics. It has many pathways or signal traces to support and electrically connect many electronic components with one another. Moreover, this board is designed with fiberglass or any other laminate material.

What are the different types of PCB?

PCBs have different types based on their frequency, substrate and number of layers. Some popular types are here for you. After studying this article you will be able to understand the whole concept of PCB and its major types.

· Single-Sided PCBs

These PCBs contain merely single layer of substrate or base material. However, these are very popular kind of circuit board. A thin coating of metal, such as copper, is applied to the layer, which is a good conductor of electricity. Furthermore, a protective solder mask is put on top of the copper layer, coupled with a silkscreen coat, on these PCBs.

ü Advantages:

- Firstly, single-sided PCBs are used for mass manufacture and are inexpensive.

- Then these PCBs are easy to manufacture.

- Another advantage is that they are suitable for low-density designs.

- If something goes wrong with these PCBs, they are simple to repair.

- This kind of PCB is easier to design than others.

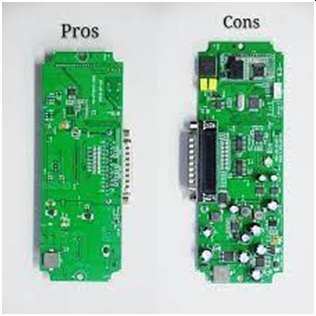

· Double-Sided PCB

Double-sided PCBs have metal conducting layers on both sides of the substrate. This kind PCB uses one of two mounting systems. Moreover, through-hole technology involves placing lead components into pre-drilled holes on the circuit board. Furthermore, it solders them to pads on contrasting edges. Surface mount technology entails placing electrical components directly on the circuit board’s surface.

ü Advantages

- These PCBs have a minimum size, which makes the circuit more compact.

- The next advantage is that they are less expensive.

- More flexible PCBs are these.

- Furthermore, this type has a strong benefit of having increased circuit density.

- Finally, another main advantage is that these are appropriate for unconventional electronic structures.

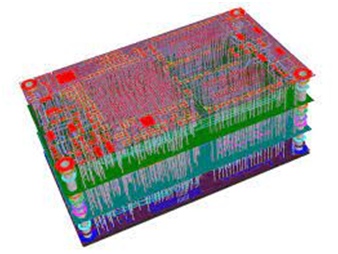

· Multi-layer PCB

PCBs with more than two copper layers, such as 4L, 6L, and 8L, are multi-layer PCBs. The technology utilized in double-sided PCBs has expanded with these PCBs. In multi-layer PCB, several layers of the substrate board works to separate the layers. The PCBs are small in size and offer weight and space savings.

ü Advantages:

- Ø Multilayer PCBs are compact.

- Ø These are more robust than others.

- Ø A high level of design flexibility is their major quality to remember.

· Rigid PCB

Rigid PCBs have a base material that is produced from a solid material and cannot be bent. These kinds of PCBs have many unique advantages those are not there in other types of PCBs. Some of their advantages are here.

ü Advantages:

- Cost-effectiveness is the main quality of these PCBs.

- Moreover, these PCBs are easy to diagnose and repair.

- Another remarkable feature of these is their low electronic noise.

- Another advantage is that these have a strong ability to absorb vibrations.

- Compactness is also worth mentioning because of the quality of this type.

- Lastly, another benefit is its lightness.

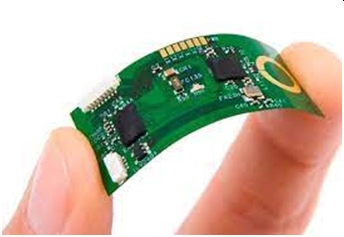

· Flexible PCBs

The flexible base material is used to make flexible PCBs. Single-sided, double-sided, and multilayer PCBs are available. This reduces the amount of complexity in the device assembly. Moreover, these types of PCBs are more flexible than others. Due to this quality these are much popular among the customers. Here are some of these advantages.

ü Advantages:

- Flexible PCBs have a major advantage in that they save space.

- They have eliminated the connectors.

- Thermal management is superior in these conditions when compared to others.

- They provide uniform electrical characteristics for high-speed circuitry.

- It is suitable for uses that need a high signal trace concentration.

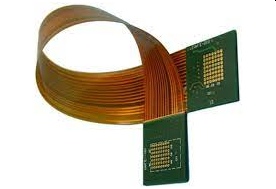

· Rigid-Flex-PCB

Rigid-flex PCB is amalgam circuit boards that syndicate both the rigid and the flexible circuit boards. They’re made up of many layers of flexible circuits that are attached to multiple stiff boards. These PCBs are the most popular due to their characteristics. Some of the advantages are here for you.

- These are used in a variety of medical and military settings due to their size.

- Due to their small weight, these PCBs save about 60% of the weight and space.

- These have 360-degree bendability.

- Because of the 3D capability, space requirements have been reduced.

- These types of PCBs are strongly shock resistant.

- Moreover, rigid flex PCBs have strong reliability.

- Another worth mentioning quality is their low weight.

- In these PCBs connection reliability is much better than others.

· Aluminum backed PCB

This kind of PCB has high-power applications due to their aluminum architecture. Aluminum-backed PCBs are known for their great rigidity and minimal thermal expansion, making them excellent for applications that require a high level of mechanical tolerance. LEDs and power supplies are installed on the PCBs.

· High-Frequency PCB

The need for PCBs is increasing in a variety of industries. Various reputable PCB manufacturers and distributors serve the competitive connecting devices market today. PCBs for industrial and commercial usage should always be purchased from reputable manufacturers and vendors.

Types of PCBs According to Mounting System

- Through-hole PCB

- Surface-mounted PCB

v Through-hole PCB

On this type of PCB, we must drill a hole in the board. This technology is beneficial because it provides greater mechanical support for electrical components and is a very dependable technology for component mounting, but drilling in the PCB increases the cost. This mounting method is simple to implement on single-layer PCBs, but creating holes on double-layered and multi-layer PCBs is more difficult.

v Surface-mounted PCB

Components on this sort of PCB are modest in size because they have very short leads or none at all for placement on the board. SMD components are directly installed on the board’s surface in this technique, which eliminates the need to drill holes in the board.

Summary

DO you want one-stop solution for pcb fabrication, Victory PCB is the first choice of hundreds of customers around the world.