Block Diagram

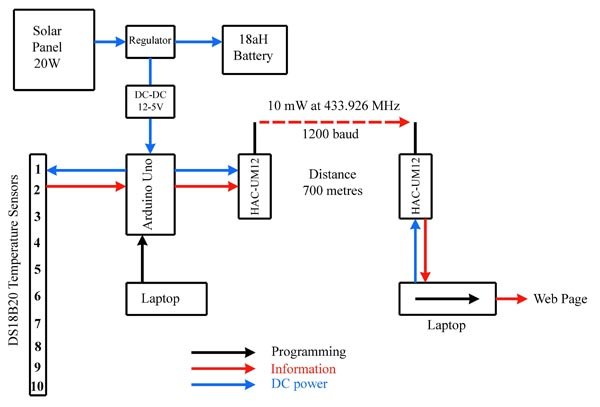

This diagram shows the basic components required for collecting temperature readings from seawater and transmitting the data to a base station where it can be collated into a database for analysis. To the left is a schematic of 10 temperature sensors, spaced 1 metre apart and immersed in seawater to a depth of 10 metres. This is connected to an Ardiuno Uno microprocessor which has been programmed to collect the readings and pass them on to a radio transmitter. The Arduino board requires a 5V supply which is provided by a DC-DC converter. This is supplied by a sealed lead acid 12V battery and solar panel with regulator. The Arduino Uno board is programmed via a usb cable connected to a laptop, and of course is disconnected when the program is uploaded into the microprocessor. The Arduino Uno board passes the temperature data to a small radio transmitter which is received by a receiver about 700 metres away. This passes the data into a laptop via a serial/usb dongle. Software reads the incoming data and massages it in various ways and dumps it into a database. Some preliminary analysis is carried out and results sent to a web page.

The ‘wet end’ of the system at sea is automated to read the 10 temperature sensors 10 times in quick succession, send this data, and then go to sleep for 20 minutes to save power so that the solar panel can keep up with current drain from the backup battery. The battery voltage and number of hours of continuous operation are transmitted at the end of each radio transmission. Fluctuations in battery power are monitored with software at the ‘dry end’, the receiving station on land. This acts as an early warning that the solar panel may not be keeping up with power consumption so that action can be taken to avert interuptions in data flow.

During any one 24 hour period some 7,200 temperature readings are collected from 10 depths. The total data flow is quite modest: each transmission is 13.6 kb, or 0.98 mb per day. The two radios are factory programmed at 1200 baud to facilitate the most reliable passage of data to the receiver. Even so, occasional transmission errors occur. In such cases, examination of the characters received suggests the receiver has been swamped by RF from some other source. Automatic detection of such problems is relatively simple and is further discussed below.

The Temperature Sensor

The Temperature Sensor

The heart of the system is a digital temperature sensor made by Maxim Integrated Products. The device is labelled DS18B20 because it was originally made by Dallas Semicondutors. Maxim acquired the Company in 2001 and continued the device name.

The device will report temperatures in the range of -55 to 125°C, and is reputed to be accurate within the range ± 0.5°C, though exactly how this calibration on an absolute scale has been achieved is not clear. I have twice requested technical information from Maxim on this point and was simply re-quoted the statement of accuracy in the manual without further explanation. It would be an interesting experiment for first year university Physics students to test this claim. Thermal calibration usually involves using some fixed points like melting ice and boiling water, but controlling all the environmental variables to within ± 0.5°C and then measuring it is not an easy task. What would one use – perhaps a DS18B20?A more important issue is the possibility of drift of various kinds, or reports from the device which vary during the length of time taken for interrogation, charge up of capacitor, heating of wire carrying current, etc. This is not a trivial matter when you consider that seawater temperatures at 10 metres depth are not likely to change quickly, depending on the exact character of tidal streams at a specific locality. Deciding whether a reported change of 0.5°C is real or not is not so simple.

There is a clear message here, ‘dont believe everything you read in the newspaper’. A digital readout of 17.31°C is impressive, especially if it is only measured once. This is the reason why in the block diagram described above, each sensor is measured 10 times, and these 10 reports are sent to the ‘dry end’ for scrutiny. More of this later.

Each sensor has a unique 64-bit serial code stored in an onboard ROM. These must be identified so they can be used later during interrogation for temperature readings. Paul Stoffregen has written a software library which can be used by the Arduino Uno board for communicating with the DS18B20 sensor. The ten sensors in the array being used here have these addresses:

0x28, 0xD3, 0x0F, 0xE5, 0x03, 0x00, 0x00, 0xC0 0x28, 0x14, 0x07, 0xE5, 0x03, 0x00, 0x00, 0xE4 0x28, 0xCE, 0xF8, 0xE4, 0x03, 0x00, 0x00, 0xA9 0x28, 0x24, 0x10, 0xE5, 0x03, 0x00, 0x00, 0x24 0x28, 0x24, 0x03, 0xE5, 0x03, 0x00, 0x00, 0x16 0x28, 0x30, 0x10, 0xE5, 0x03, 0x00, 0x00, 0xA3 0x28, 0x78, 0xFC, 0xE4, 0x03, 0x00, 0x00, 0x03 0x28, 0xA8, 0x0D, 0xE5, 0x03, 0x00, 0x00, 0x23 0x28, 0x99, 0xDA, 0xE4, 0x03, 0x00, 0x00, 0x79 0x28, 0xA2, 0xE8, 0xE4, 0x03, 0x00, 0x00, 0x6B

Two software libraries are required when writing code for the Arduino Uno board to communicate with the DS18B20 sensors: OneWire and Dallas Temperature. Jim Studt created the original OneWire library in 2007, and this is now maintained by Paul Stoffregen. The latest version 2.1 can be downloaded from here. The second library, Miles Burton’s Dallas Temperature Control library can be downloaded from here. These libraries are open source software.

There are three terminals on the DS18B20 sensor: GND, DQ, and VDD. The device can be powered directly by the DQ Data Line, requiring 3.0V to 5.5V. If this is done, the VDD terminal can be strapped to GND, as shown in this diagram to the left. The thermometer resolution is user-selectable from 9 to 12 bits, and it converts temperature to a 12-bit digital word within 750 ms. When several sensors are being used, they may be mounted on a single rail as shown. A request from the Arduino Uno board to this rail for a temperature reading using one of the serial codes above returns the value from the appropriate individual sensor. This is referred to as the One-Wire Configuration. Strictly speaking two wires are required of course, the DQ and GND wires. This configuration is easy to assemble on two wires, but if waterproofing is required it is not at all simple. Coating two wires with multiple sensors attached with shrink-wrap might be splash proof, but it certainly would not be waterproof, especially if immersed in 10 metres of seawater with a surrounding fluid pressure of 1,000 mbar. This is the difference between a water resistant watch which is splash-proof, and a diving watch which is genuinely waterproof under pressure with ISO-6425 rating.

It would be possible to make a single waterproof cable with multiple sensors on it, but it would be quite complicated. A much simpler design is the so-called Star Configuration, also shown to the left. This involves running separate cables to each sensor and joining them on to the one wire rail at the far end from the longest cable. This is much easier to waterproof, although another problem arises, though relatively easier to solve than with the one-wire configuration. Fortunately, there are numerous manufacturing companies making waterproof versions of the DS18B20 sensor. The sensor is attached to a coax cable with three wires soldered on to the sensor terminals and the sensor and bare wires are then inserted into a stainless steel tube bucket and filled with thermally conducting resin, thus waterproofing the metal parts of the sensor and wires. The special resin assists with transferring thermal enegery from the surrounding environment through the stainless steel to the sensor itself. Unfortunately, marine #316 grade stainless steel is not used by these companies, but the less corrosion resistent #304 grade. In addition, as is well known, stainless steel is a very poor conductor of heat, so we can expect a small time-lag in the sensor respoding to temperature changes in the surrounding seawater. Stainless steel #304A grade has a thermal diffusivity (the measure of thermal inertia) of 4.2 mm2/s compared to copper of 110.8 mm2/s. What the additional time-lag is as a result of using the thermally conducting resin is not known.

Most of the companies manufacturing waterproof DS18B20 sensors make them with various custom lengths of coax attached, but one company, Shenzhen VIIV Technology Co. Ltd. in China, offered to make a one-off cable for me with 10 coax cables cut at lengths of 10m, 9m, 8m, etc and bundle all cables together and coat the outside of the stainless steel buckets with additional resin for enhanced corrosive resistance (see image to the right). The final overall length was 14m and cost US$190 including shipping. The contact person for this order was [email protected].

As mentioned above, this star configuration with multiple wires starting from one point, each leading to a sensor, raises a small problem. Depending on the total length of wire in the system, spectacular false readings of -127.00°C are sometimes generated, or simply 0.00°C. In cases like this the 4.7kΩ resister needs to be reduced to allow more current to flow to the wire which charges a capacitor inside the DS18B20 sensor. Paul Stoffregen suggested lowering the value to 1kΩ, and if this still failed to work to try 470Ω. I wanted to add an additional 10 metres of three wire cable on to the end of the bundled-up 10 coax cables for attachment to a distant box of electronics, so considerable experimenation was required to find the highest resistor that produced consistently reliable temperature reports. The final resistor was a 1% tolerance 480Ω resistor.

There is a total of 30 wires from the bundle of 10 coax cables requiring termination. Each of these was examined for continuity with somewhat surprising results. The DC resistance from the shield of each individual coax to each wire leading to the three terminals of each DS18B20 was found to be the following. NB: the “>” symbol is used when a resistance is off scale on the 2,000 MΩ range. These results suggest that there is a short between the GND wire and the shield in the case of the 3 metre cable. This shield also has a lower than expected resistance with both the VDD and DQ wires for this same cable. Whether this is a problem or not remains to be seen. Finally, coax cables for both the 8 and 9 metre lengths exhibit lower than expected resistance, although still very high.

All the GND wires are soldered on to one single terminal in the termination box, and this was done with the VDD and DQ wires. A 10-metre-long three-wire heavy duty cable was then soldered to the same terminals and led away to the main box carrying the electronics. Although not shown in the image below this termination box is then filled with Sika Marine ISP-919 Silicone sealant. Although not immersed in seawater, this box is exposed to the elements for long periods and this treatment completely waterproofs the box and its contents.

Antifoul Protection of the Cable

Because the monitoring cable was scheduled to be immersed in seawater for up to two years it was necessary to coat the cable with marine antifoul paint to deter organisms from growing on it. Moorning lines in Ngakuta Bay attract both green-lipped and blue mussels (Perna canaliculius and Mytilus galloprovincialis ) as well as numerous other smaller species. The Cable was attached to a 15 metre long 1cm diameter polyester double braid rope which has minimal stretch using nylon self-locking fasteners. A zinc anode was attached to the end of the rope weighing 2.6 kg. This is designed to hold the cable vertical in the water.

David Pook of Westshore Marine Ltd kindly donated four litres of Altex Coating Industrial & Marine antifoul on the cable. The cable was coiled up and immersed in a large can of antifoul each morning and hung up to dry. This treatment was repeated over four successive days to ensure a thick coating on the cable. After the final coat it was left hanging for five days to ensure full hardening.

Solar and Battery Power Supply

Running electronic equipment 24 hours a day and 365 days of the year from a battery with re-charging by solar panel requires careful attention to current use and a conservative estimate of delivery from sunshine.

A useful guide to what one might expect from various sized solar panels in London and Edinburgh can be found here. These are average values with the solar panel mounted at optimum angle to the sun. The average sunshine in London is about 1,500 hours per annum, and for Edinburgh about 1,350 hours per annum. New Zealand values compare favourably to these. There are no estimates for Ngakuta Bay, but values for nearby locations are: Auckland and Wellington are both about 2,050 hours per annum, Nelson 2,400 hours per annum and Blenheim 2,500 hours per annum. A conservative estimate for Ngakuta Bay would be about the same as Wellington.

Previous reports of power consumption of the different components in similar recording systems vary widely. There are some reports of about 25 mA for the Arduino Uno board, but Windows 7 reports the USB root hub properties requiring 100 mA. The DS18B20 sensors are rated at requiring a maximum of 1.5 mA each when operating and 1 mA on standby. The radio transmitter being used is rated at 32 mA when receiving, 42 mA when transmitting, and 5 μA when in sleep mode.

Total power consumption was measured when using a battery delivering 12.2 V, and found to be 64.8 mA during the transmitting part of the cycle, 41.4 mA during the standby period, and 28.0 mA during sleep mode. One cycle consists of the following elements which were timed with a stop watch:

Step 1: collect and transmit temperatures from each of the 10 sensors, taking 1.99 seconds.

Step 2: standby, taking 4.69 seconds.

repeat steps 1 and 2 ten times, then

Step 3: sleep for 20 minutes.

A complete transmitting and standby cyle therefore takes (1.99+4.69)*10 = 1 minute 6.8 seconds, with 20 minutes sleep, totalling 21 minutes 6.8 seconds. Each transmitting cycle is time-stamped, and the average gap between them is 21 minutes 10 seconds, which accords well with the stop watch values. During any one 24 hour period there are approximately 68 full cycles. The total power consumption during a 24 hour period can thus be calculated as follows:

Step 1: 64.8 mA for 1.99 seconds = 0.0358 maH.

Step 2: 41.4 mA for 4.69 seconds = 0.0538 maH

repeat steps 1 plus 2 ten times = 0.8962 maH, followed by

Step 3: 28.0 mA for 20 minutes = 9.3333 maH

which is a total of 10.2296 maH per full cycle

The 68 cycles per 24 hour period would therefore consume 695.6115 maH

The total daily power consumption is therefore apportioned as follows:

Transmitting = 24.3576 maH, 3.5%

Standing by = 36.5872 maH, 5.26%

Sleeping = 634.6667 maH, 91.24%

Total = 695.6115 maH, 100.00%

These are very interesting results. Clearly, the power consumption actually doing anything is trivial compared to the amount of power being used sitting around waiting to do something. What might we expect from the solar panel becomes the next question. We can expect about the same sunshine hours at Ngakuta Bay as the lower New Zealand values of Wellington and Auckland at about 2,050 hours per annum, or about 1.37 times the values for London at 1,500 hours per annum. The average yield in London of a 20 watt solar panel during winter would be about twice the value for 10 watts (0.41*2), say 0.82 aH per day, which should correspond to approximately 1.37 times that value for Ngakuta Bay, or 1.12 aH per day. However, it will be remembered that the London values were with the solar panel mounted at optimum angle to the sun. This will not be possible with the array being used here. The solar panel along with the electronics and cable in the sea will be mounted on a private vessel moored in Ngakuta Bay. The vessel will move about on the mooring line during the day 360°, and the best possible angle for the solar panel will be flat horizontal to catch the greatest sunshine. The angle of the sun at various times of the year at Wellington, which is very close to the Latitude at Ngakuta Bay, is well documented. The best time of the year is the summer soltice on December 22 at 72.2° elevation, followed by the two equinoxes of March 21 and September 23 at 48.7° elevation, and the winter solstice of June 22 at 25.2° elevation. The solar energy falling on a horizontal panel when the sun angle is 25.2° elevation would be approximately 72.5% of that which would fall on a panel at the optimum angle to the sun.

So we can estimate that during the winter solstice at Ngakuta Bay, approximately 1.12 * 0.725 aH would fall on our horizontal 20 watt solar panel, which is about 0.812 aH per day. Our calculated power consumption per day was 0.696 aH per day, so there appears to be about a 17% margin of safety in the solar panel rating for mid-winter. This is not a large margin, but hopefully will be enough.

The main power source is a DiaMec DM1218 12V-18 aH sealed battery, and there is a MP3128 PV Solar Charge Controller between the battery and the solar panel. This controller is rated at 26 volt and 6A maximum rating. This battery and controller and all electronics are inside a special waterproof box with the solar panel mounted on the top (image above right). All external bolts and feedthroughs are covered with silicone sealant to ensure waterproofing. There are two rings on each corner of this box for tying it in a secure location on board the vessel at sea. All engineering is aluminium alloy with marine grade #316 stainless steel bolts and nylox nuts. The engineering costs were $367

The Arduino-Uno Board

After considerable experimentation, this schematic on the right shows the final wiring of the Arduino Uno board to power supply, radio transmitter, and the cable with DS18B20 sensors. The Arduino Uno board has an on-board 12V to 5V converter but it was thought there might be some power savings by having an external switchmode DC-DC power supply based on the #7805 converter.

The two resitors shown near this power supply act as a voltage divider fed into Pin A0 on the Arduino Uno board. This provides digital data as a proxy of the condition of the 12V battery. More of this later. The input feed from the cable with the DS18B20 sensors shows the 480Ω resistor, discussed earlier. The value of this resistor was decreased from the standard 4.7kΩ normally used for the one-wire configuration also discussed earlier, and illustrated to the right.

The VDD wire is latched to earth as power to the sensors is being provided in parasitic mode. We experimented with providing power to the sensors on the VDD wire, but found this to be less reliable than parasitic mode with such long wires in the star configuration. The reason for this is not clear.

The digital data from the DS18B20 sensors comes in on Pin 10, and is sent out to the serial port on the Rx Pin 3 of a DB9 connector, while the Tx Pin 4 is left open. Instructions for sleep and reset are sent out from Pins 3 and 4 on the Arduino Uno board to Pins 8 and 9 on the serial connector. Note that the second set of Rx and Tx pins on the serial connector is unused, Tx Pin 6 is held high through a 4.7k resistor, and Rx Pin 7 is left open.

Given the hostile marine environment that this supposedly waterproof box containing electronics is to be kept in for long periods, it was thought desirable to include a humidity sensor, which could be monitored along with the output of temperature data. If moisture entered the container for any reason, this would be an early warning of such a problem and could be attended to before the problem became serious. A suitable device would be the AHT15 digital humidity sensor, readily available here. There is an Arduino library for this device. There are plenty of spare pins on the Arduino Uno board for input from such a device. This has yet to be implemented.

Keeping an Eye on Battery Power

It is hoped to monitor the 10 temperature sensors continuously for a minimum of two years, and clearly one of the most important factors is continuity of power supply from the battery. Although every effort was made to build in safety margins, a long period of low-level sunshine could prevent the solar panel from charging the battery to an acceptable level. For this reason, battery voltage is transmitted along with temperature data and continuously monitored. The information is automatically uploaded to this web page every day during each monthly cycle. An alarm system has been implemented in the software as an alert that attention is needed out on the water. The rising and setting of the sun are evident in the graph on the left.

For more detail: Technical Details of Logging Seawater Temperature