The Pi is a fine little computer board, though not nearly as good as

the Arduino when it comes to I/O capabilities. The beautifully-engineered

Gertboard is a plug-in add-on that neatly overcomes this deficiency

by giving the Pi access to an ATMega328, but it’s a very complex and

expensive solution. An alternative would be to interface an Arduino

running at 3.3 volts to the Pi, though this is easier said than done.

But, we won’t let that stop us, will we?

of something similar to this project.

It’s called an AlaMode, and it goes for something like $50.

Our version will cost about a third of that to build.

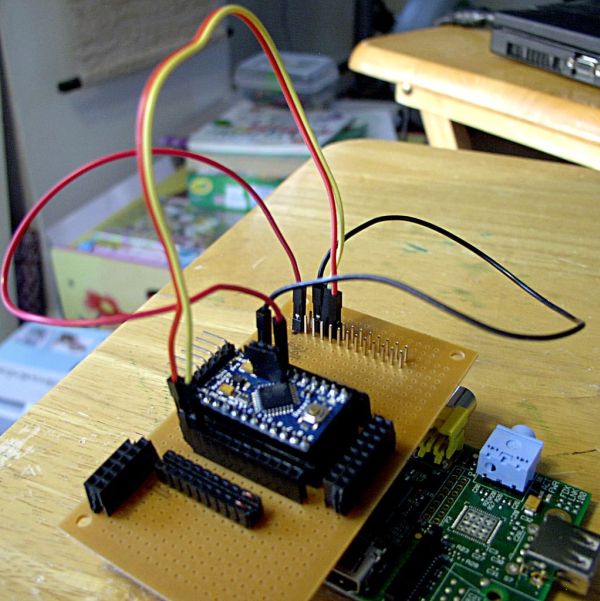

As a first step, we will build an Arduino plug-in board for the Pi.

It is customary to call Pi boards “plates,” but indulge me and permit

me to name this particular board a hoody. Thank you.

We will be using generic stripboard to build our project. Small (3-3/4″

x 2-1/16″) boards can be obtained on eBay for a bit over a dollar apiece.

It is also possible to use something like a Radio Shack 276-168 protoboard

($3.49). The main component, though, is an 3.3-volt Arduino Pro Mini.

This will permit connecting directly to the Raspberry Pi ports and other

3.3-volt devices without having to do level shifting.

directly to the GPIO pins. This is not a good idea. Use buffer chips,

such as the 74HC4050 hex buffer, between the devices and the GPIO.

This protects the Pi from overvoltages, current surges, and your mistakes.

Far better to blow out a fifty-cent buffer chip than a $35 Pi.

This particular project connects directly to the GPIO Rx and Tx pins.

However, we are connecting to a 3.3 volt device, which limits the risk.

Still, a buffer chip would not be a bad thing here.

This is a moderately complex project, and beginners need not apply.

It requires skill at soldering and in the use of hand tools. Experience

with a continuity tester and a steady hand with a knife blade are also

helpful.

Ready? Well, then, let’s get on with it!

Step 1: Parts needed

- Arduino 3.3-volt Pro Mini clone

- 1 – stripboard (protoboard), 3-3/4″ x 2″ or larger

- 1 – 24-pin wire-wrap socket ***

- 1 – 26-pin, stacking header

- 2 – 40 pin female header strip (as for Arduino projects)

- 4 – female-to-male jumper cables / patchcords

- Nokia 5110 display (optional, but recommended)

- Raspberry Pi, model A preferred (lower power drain)

- Video display for the Pi, Atrix lapdock recommended

- Hookup wire

Nothing terribly exotic, folks, and fairly cheap to get, too.

Cost:

- stripboard $1.25

- wire-wrap socket $1.50

- stacking header $2.00

- jumper cables $4.00 (for set of 40)

- female header strips $1.00

- Nokia display $6.00

- Arduino pro mini (or clone of same), 3.3 volt model $7.00

Total is under $25, if you don’t already have any of the components laying

around.

Tools:

- Soldering iron

- wire cutters (Plato 170 or similar)

- sharp knife (or optionally a Dremel-type rotary tool)

- continuity tester (preferred) or a multitester

Notes:

will not fit into the holes. But, you can substitute two 14-pin strips offemale headers.

Some examples of such are the Boarduino and Ardweeny.

Be aware, however, that the ATMega328 chip is not rated to run at 16 MHz powered

at 3.3 volts. So, you would be running it out of spec, or essentiallyoverclocking it.

I’ve done some experimenting with this, and at least some, maybe most ATMega328s

can be programmed and run at 3.3 v. But, of course, your mileage may vary.

Step 2: Building the board [1]: Installing the GPIO header

I used a stripboard to build the Raspberry Pi interface

board/hoody. Stripboard has the advantage of design flexibility —

it does not constrain the component layout to any particular configuration.

It’s also much cheaper than equivalent-sized solderable protoboards.

The chief disadvantage of stripboard is the necessity of extensive cutting

of copper traces on the solder side.

A rough diagram on a sheet of paper helps.

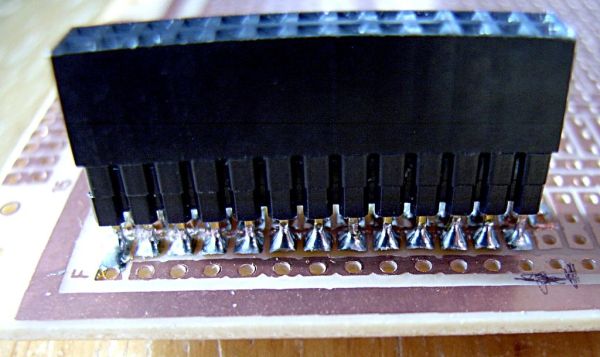

I mounted the 26-pin stacking (long-pin) GPIO header near one edge

of the board, with the female (plug-in) part of the header on the

copper-trace side. The trick is for the header not to mount flush

against the board, but to stand off about 1/4″ high in order to permit

soldering the pins to the copper traces. But, first we need to cut

thirteen rows of traces where the GPIO header will mount, so that adjacent

header pins will not be shorted to each other (see 2nd and 3rd illustrations).

Cutting the traces requires going back and forth with a sharp knife blade

with a fair amount of pressure (caution!), then follow-up checking with

a continuity tester. It’s a fair amount of work, and next time I try

something like this I’ll probably use a Dremel tool with cutting disk,

rather than a knife.

With the thirteen traces cut, carefully mount the GPIO header

approximately 1/4″ in elevation. This will give enough room to maneuver

the tip of the soldering iron between the pins to solder them. A couple

of dabs of poster-mounting putty hold the header in position prior to

soldering. Solder one end pin, then carefully straighten out the header

so it sits perpendicular to the board. Solder the remaining pins, then

use the continuity tester to look for shorts beween pins, both sideways

and across. A good continuity tester with audible indicator is especially

helpful here.

After soldering, the header pins will protrude 1/4″ or a bit more on the perfboard

(non-solder) side. This is convenient, as these will function as posts to attach

patch-cords and jumpers. Each post will be an electrical connection to the

corresponding GPIO pin underneath when the board is mounted on the Pi.

Step 3: Building the board [2]: Installing the Arduino socket

The interface board needs a means of plugging in an Arduino, and

specifically a 3.3-volt mini Arduino Pro. This is where the 24-pin

wire-wrap socket comes in. For some reason, the Arduino Pro module neatly

plugs into a wire-wrap socket, but the pins are too fat for a regular

24-pin socket. Fortunately, wire-wrap sockets are widely-available and

not too expensive. I happened to have a couple laying around from a 2716

EPROM project I was working on several decades back.

Position the socket about an inch down from where the two rows of posts

stick up from the GPIO header on the perfboard side (see pics). Solder

the socket flush onto the board. After soldering, clip the protruding

pins flush on the copper-trace side of the board. Then, cut the rows

of copper traces between the two rows of soldered pins on the socket,

so that adjacent pins do not short together.

From the 40-pin female header strip, clip off two 12-pin strips.

On the perfboard side, position a 12-pin female header strip on each side

of the IC socket. This will provide plug-in points for jumper-wires to

access the Arduino pins. Secure the header strips so they are vertically

positioned relative to the board. Now, turn over the board and solder

each row.

There are no notches, as with male header strip, so the clipped-off

strips will usually come out a bit ragged, but this hardly matters. The

trick is to clip in the middle of a hole, and this will either leave

a metal prong hanging, or the prong will just fall out. It wastes one

hole of the strip each time you clip, but there is no avoiding this.

There is a piece of female header strip left over. Clip off an 8-pin

strip from it. You will have to get the second 40-pin strip in order to

be able to clip the second 8-pin strip because one pin always gets wasted

in the clipping process. These two strips will make up a socket for an

optional Nokia 5110 monochrome display for our project. The two rows will

short together on the solder side, so jumper wires can be electrically

connected to the pins of the Nokia display. Position the strips, then

turn over the board and solder them. Finally, cut rows of copper traces,

so that the Nokia socket is electrically isolated from everything else.

I installed two dual-row “utility” socket strips on the periphery of

the board. The installation and soldering procedure is the same as that

for the Nokia socket. The actual number of pins in these socket rows is

arbitrary, but they are useful for power and ground busses, among other

things. After soldering, cut appropriate rows of copper traces to isolate

these strips electrically from the rest of the board.

Step 4: Wiring it up: Part 1

Now that the interface hoody is built, where do we go from here?

We must still plug in the Arduino Pro and the Nokia display into the

sockets we’ve prepared. Then, we’ll run jumper wires and patch-cords —

from the Arduino to the display, and, in the following step, from the

Arduino to the GPIO posts.

to solder a row of male headers to the 8 solder holes for the power

and date lines. Take note of how the holes are labeled.

Nokia 5110 displays, unfortunately, do not have a standard pinout

configuration. They do all have the same complement of pins, but they

are not necessarily in the same position on the display board’s

connector. Even the labeling of the pins varies, though they still

have the standard functions.

- Arduino Nokia display pin name Nokia display pin number

- (Digital)

- pin 7 – Serial clock out (SCLK) varies

- pin 6 – Serial data out (DIN) (see pin labels on display)

- pin 5 – Data/Command select (D/C)

- pin 4 – LCD chip select (CS)

- pin 3 – LCD reset (RST)

- Vcc –> Nokia Vcc (3.3 v.)

- Ground –> Nokia Ground

- Vcc –> Nokia backlight

If possible, use different colored jumper wires for each function,

say red for Vcc, black for ground, and appropriate colors for the

data lines. This will make it easier to trace the connections and to

double-check your work. Work slowly and meticulously, and be especially

careful not to make any errors with the Vcc and ground connections.

Note that in the illustration the two end pins in each strip of the Nokia socket

have wire jumpers. This is because I used 10-pin strips, and the Nokia display

uses only 8 pins. The jumpered holes are blocked from use.

We’re almost done with the hardware part of the project, so you can stop

and have a cup of coffee.

Step 5: Wiring it up: Part 2

Time to connect up the GPIO header posts with the Arduino pins.

We will use female-to-male jumper patch-cords.

There are only four, count ’em, four connections to make.

Here is where the two rows of female headers alongside the Arduino socket come

in handy.

- Vcc (3.3v) on the Arduino connects to the GPIO Vcc (3.3v) pin: Pin #1.

- Ground on the Arduino connects to the GPIO Ground pin: Pin #6.

- TxD on the Arduino connects to the GPIO RxD pin: Pin #10.

- RxD on the Arduino connects to the GPIO TxD pin: Pin #8.

Note that TxD connects to RxD, and vice-versa. The reason for this is that

signal-out on one device goes to signal-in on the other. It’s a bit confusing

at first, but quite logical when you think about it.

To facilitate tracing and troubleshooting, use a red jumper for Vcc and a

black one for ground, and two other colors for TxD/RxD and RxD/TxD.

Check your work, and be especially careful with Vcc and ground. A mistake

here could be costly.

Whew! All done with the hardware! Now, on to the software.

For more detail: The Raspberry Pi – Arduino Connection