here is growing interest in the commercial production of high-value specialty fruit such as strawberries, blackberries, raspberries, and blueberries. Much of the small fruit grown in North Carolina is currently marketed through pick-your-own establishments or roadside stands. A strong demand for these small fruit items from grocery stores and restaurants has prompted many growers to consider expanding their production to take advantage of these new marketing opportunities.

These commodities, however, are extremely perishable and normally require immediate postharvest cooling before shipping to prevent degradation. Expansion into the commercial small fruit market would usually require a considerable investment in postharvest cooling and handling facilities, and possibly refrigerated transport. The risks associated with a new venture and the considerable cost involved prevent many growers from taking full advantage of this marketing opportunity. Small portable cooling units designed to “plug in” to small, insulated shipping containers have been used by the world’s airlines and ocean freight carriers on a limited basis for more than 30 years. These units typically have been utilized for mainte- nance cooling of precooled, highly perishable produce during transit or during extended stop- overs or delays. This publication gives instruction for building and using a similar, inexpensive cooling system. The Cool and Ship system provides rapid cooling for modest amounts of small fruit and is versatile, portable, reusable, and inexpensive. The system uses an air-conditioning system and com- mon building materials, and may be easily assembled by the user.

Small fruit such as blackberries, strawberries, and blueberries are very perishable and require immediate cooling after harvest to prevent a rapid decline in quality. At warm temperatures, softening and decay can occur in less than four hours. Rapid and thorough cooling is essential to quality maintenance.

The preferred and most commonly used cooling method for small fruit is forced-air cooling. Forced-air cooling uses a refrigerated room equipped with fans that pull large volumes of cold air through palletized packages of produce. The close contact between the moving, cold air and the warm fruit causes a much more rapid decrease in temperature than would occur otherwise. In addition, forced-air cooling removes droplets of water (dew or rain) from the surface of the fruit. Warm, wet fruit is very susceptible to postharvest rots.

Although growers sometimes receive a premium price for cooled produce, the benefits of cooling are often more indirect. They may include better appearance, a much longer shelf life, and the pride that comes from marketing a high-quality product. However, the most important indirect benefit is the marketing advantage cooled produce has over uncooled produce. In a buyer’s market, with other factors being equal, cooled produce always sells better because buyers associate cooling with quality.

| Advantage of the Cool and Ship SystemInexpensive—low initial cost compared to a stationary cooling facility.Reusable—can be disassembled for easy transport.Transportable—no need for a refrigerated truck. Versatile—can be used for a variety of produce. Energy Efficient—takes less energy than a stationary facility. Protects the Produce—prevents condensation or contamination. |

Equipment

Building the Cooling Container

The cooling container shown in the centerfold drawing consists of a top, bottom, and four side panels of 2- inch-thick sheets of extruded polystyrene insulation, commonly referred to as blueboard. This insulation material is manufactured in panels measuring 4 feet by 8 feet, is safe for use as food packaging, and is reasonably durable when handled with care. Sheets of polystyrene beads (whiteboard) may be substituted for blueboard, but they are not nearly as durable.

A sheet of 1/4-inch-thick CDX-grade plywood or chipboard is bonded to the insulation material for added rigidity and protection from damage. Exercise care when selecting the adhesive. A white glue compatible with both the wood and the polystyrene insulation material must be used. Spread the glue evenly in a thin layer on the insulation board with a brush or wide putty knife. Carefully position the plywood on the insulation and firmly press together. As the composite panels are completed, they may be stacked one upon the other on the floor or other flat surface. Adding weight to the top of the stack is beneficial because full contact between the plywood and insulation is essential for a strong bond. Be careful to wipe off any excess glue that squeezes out between the panels. Five full-sized panels are required for each container (four for the sides and one cut into halves for the top and bottom).

Considering the size of the fruit packaging is important when building the cooling container. The inside dimensions of the container shown in the drawing are 40 inches deep by 44 inches wide by 72 inches tall. It will hold 144 half-pint masters, 96 pint masters and 60 quart masters while still providing sufficient void space for proper air circulation. Al- though desirable, it is not necessary that the cooling container be completely full. The pictorial view of the drawing shows an acceptable fill of 84 1 2-pint masters. The top of the cooling container is designed to move vertically, as shown in Figure 1, to accommodate various stack heights. This arrangement allows a tight fit and eliminates air short-circuits over the top of the stack of masters.

Figure 1. Fitting the top in place.

The maximum outside dimensions of the cooling container (as shown in the top views of the centerfold drawing) was limited to 48 inches because of the maximum size of the materials. However, this size is also convenient because it will fit between the wheel wells of a full-size pickup truck. An inlet and outlet plenum or air gap (also shown) of at least 1 1/2 inches must be maintained on either side of the stack of masters for air distribution. Cold air inlet and outlet holes, the size of the air distribution ducts, are cut in the center of opposing sides adjacent to the two plena. The cutouts are saved and used to seal the holes once cooling is completed.

The sides of the cooling container are fastened by pair of loose-pin strap hinges on each corner. Eyebolts are substituted for the hinge pins to facilitate assembly and disassembly. An adhesive-backed foam strip approximately 3/4 inch wide by 3/8 inch thick is used as a gasket to seal all joints between the sides, top, and bottom. The outside plywood surface s painted with two coats of outside gloss enamel for protection. The sides should be numbered at each of he top corners to be certain they fit together properly. The cost of the materials for each container is approximately $150, and the unit takes two persons approximately 1 1/2 hours to construct.

The sides should be numbered at each of the two top corners to be certain they fit together properly.

Refrigeration Unit

Often, even relatively low-capacity commercial refrigeration units are not sold as a complete unit but as components. The selection of compressors, condenser coils, evaporator coils, piping, and other components is customized for each application. The selection process requires technical competence and contributes a significant amount to the overall cost of a system. The addition of forced-air capability to such a facility likewise requires custom engineering in the selection and application of fans and controls.

On the other hand, residential air conditioning components are generally factory matched. As far as possible, major components are preassembled, requiring much less labor at the job site. Residential window units and air-conditioning systems for mobile homes are even more unitized and standardized, thus requiring little or no job-site assembly. However, unless the units are carefully selected, the use of residential air-conditioning systems for produce refrigeration can yield poor results.

Many residential air-conditioning systems are designed to cool air to 65 to 70°F and therefore normally have evaporator coil temperatures of 45 to 50°F, which is too high to provide much useful produce cooling. Fortunately, there are some air-conditioning units available with evaporator coil operating temperatures low enough to provide acceptable produce refrigeration. Among these are modular mobile home air-conditioning units. With proper selection, these units of the 2- to 3-ton range can make an excellent and relatively low-cost source of cooling. (A ton of cooling will displace 12,000 Btu per hour.) In general, those units that use R-22 refrigerant will give satisfactory results. Carefully check the unit’s specifications for refrigerant type and tonnage before making your selection.

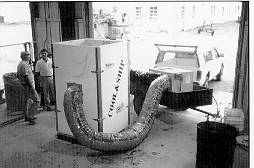

A new, 3-ton mobile home air-conditioning unit may cost up to $2,000. Used equipment may be considerably less expensive. A suitable air-conditioning system should have a fan that is integral to the unit. Such systems are normally supplied with lengths of insulated flexible ducts 10 or 12 inches in diameter. These flexible ducts can be used to connect the air-conditioning unit to the cooling container. Sheet metal flanges and clamps normally supplied with the air-conditioning unit are suitable for connecting the ducts to the container panels. One duct carries cold air to the container and the other carries the warm air back to the unit. This forms a closed air system and is much more energy efficient than allowing the air to escape as it leaves from the container.

Figure 2. Air conditioning unit with cooling container.

A properly selected air-conditioning unit should operate satisfactorily with minor modifications. One such modification is the addition of a bulb-type thermostat mounted so that the bulb is in the air intake stream of the unit. This thermostat acts as a controller that stops the entire system when cooling is completed.

Postharvest cooling should be accomplished as rapidly as possible because the cooling coils also dehumidify the air. Frequently the coils operate at temperatures below the dew point of the air passing through them. When this occurs, humidity in the air is lost as condensation on the coils. The amount of water removed from the air increases with the size of the coils, the velocity of the air, the air’s humidity, and falling coil temperatures. Even if the air is properly cooled, fresh produce exposed to very dry air for extended periods can suffer decline in weight and quality.

When the temperature of the cooling coils falls below freezing, coil icing can occur. The degree to which ice accumulates on the coils is related primarily to the coil temperature, the amount of free water on the fruit, and the duration of cooling. Ice should not be allowed to accumulate on the coils for three reasons. First, ice acts as an insulator and limits the coil’s ability to cool the air. Second, ice blocks the flow of air through the coils. Third, poor heat transfer from iced coils can cause liquid refrigerant to return to the compressor (a condition known as “slugging”) causing compressor failure. There is little chance of coil icing as long as the temperature of the air returning to the air-conditioning unit is above 45°F. To prevent coil icing at lower temperatures, a simple alteration of the power control wiring may be made that causes the compressor to cycle on and off at a predetermined rate yet allows the evaporator coil (cold air) fan to operate continually. A typical relay setting would allow the compressor to operate at a 75 percent duty cycle on 6 minutes and off 2 minutes. Any evaporator coil icing that occurred during the time the compressor is operating is melted by the relative warm air from the cooling container during the compressor off time. A schematic diagram for altering the wiring is shown in Figure 3. Always consult a licensed electrician and follow all electrical codes!

For more detail: PORTABLE FORCED-AIR COOLING UNIT