The design of electronic cards and devices now requires high flexibility and increasingly short delivery times. In a market characterized by a strong innovative drive, with increasingly shorter time-to-market, it is essential for electronic designers to rely on rapid, reliable and cost-effective PCB prototyping and assembly services.

INTRODUCTION

The development of new electronic applications in recent years has received a significant boost, mainly determined by the spread of new technologies such as the Internet of Things (IoT), Industry 4.0 and “smart” devices. As an effect, we have witnessed the proliferation of innovative solutions in all the main electronics sectors: consumer, industrial, automotive, electromedical and mobile. The need for flexibility and adaptability to rapidly evolving requirements has also determined the progressive abandonment of entirely hardware solutions, in favor of “mixed” hardware and software solutions, in which the presence of programmable components is increasingly massive. The hardware designers, the first link in the product development chain, are therefore required to produce a working prototype ina short time, which allows them to continue with the firmware development and final validation of the product. In this article we will present the services, entirely available online, offered by PCBWay, the ideal partner for PCB prototyping, assembly and more.

PROTOTYPING AND PCB PRODUCTION

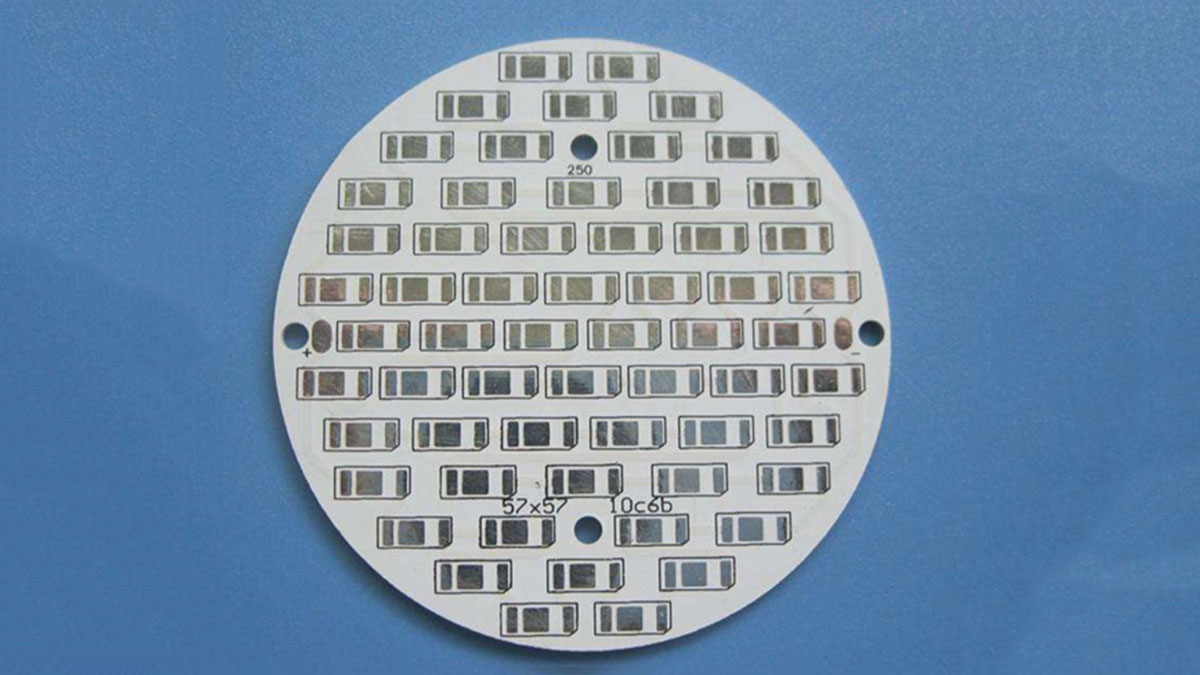

Today the market offers designers a wide range of materials and technologies for the manufacture of PCBs , among which it is necessary to choose based on the requirements of the specific application and the available budget. Traditional solutions are represented by FR-4 cards (fiberglass) and aluminum cards. FR-4, commonly known as vetronite or epoxy glass, is a composite material based on glass fibers arranged orthogonally between two layers in an epoxy resin matrix. Fiberglass is an excellent insulator, robust, light and flame resistant. The aluminum printed circuit boards are particularly suitable for power applications where high heat dissipation is required, such as industrial lighting systems and LED lights for automotive applications. Aluminum has the characteristic of being lighter, sturdier and longer lasting than vetronite. In Figure 1 is shown an example of aluminum printed circuit intended to the sector lighting .

Figure 1: high thermal dissipation aluminum PCB

The most advanced types of PCBs include Rogers boards , aimed at high frequency RF applications, HDI boards for applications with high density of connections (for example smartphones), flexible PCBs and a combination of rigid and flexible PCBs . All the PCB solutions previously listed, and others, are offered by PCBWay at a very competitive price, with

the possibility of obtaining an instant quotation (for circuits up to 14 layers) by accessing the appropriate section of the site Delivery times are very fast: 24 hours for a double-layer PCB and 48 hours for a four-layer PCB.

ASSEMBLING

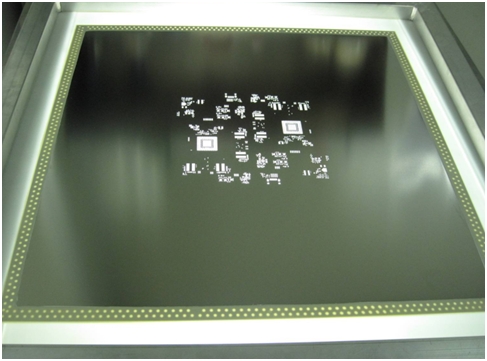

A complete and functional prototype cannot disregard the execution of a correct and accurate assembly phase of the components on the PCB . PCBWay meets designers and electronic companies by providing a professional PCB assembly service starting at $ 30, both for surface mount ( SMT ) and through-hole ( THT ) components or mixed solutions. The SMT assembly technique is performed using screen printing frames and frames (framed and unframed stencils) which present excellent stability over time and high wear resistance. In Figure 2 is shown an example of a stencil PCB, ready to be used during the assembly phase with SMT technology.

Figure 2: an example of a stencil for SMD assembly

The components required for assembly can be supplied by the customer, or directly by PCBWay which can count on a large and replenished warehouse.Through anappropriate section of the site it is possible to obtain an estimate of the assembly costs and shipping costs. To get an instant quote simply insert the number of cards to be assembled and load the Gerber files, the components list (BOM) and the file in centroid (or pick & place) format. The assembly service, able to provide professional and accurate results regardless of the volume required, includes shipping to all countries in the world.

Full ranged PCB DESIGN service

In addition to PCB production and component assembly services, PCBWay is able to offer its customers complete support in all phases of development of an electronic circuit. Taking advantage of the work of professionals and certified third-party companies, PCBWay is able to assist customers in activities such as: definition of the PCB layout starting from the wiring diagram (the main software tools are supported such as Altium Designer, Cadence Orcad, Allegro, Eagle and Kicad), circuit and mechanical design, software and firmware development for embedded systems, 3D printing. A quick and efficient listing of costs related to design services can be obtained online. Services include a service and warranty period of up to 120 days.

OPEN SOURCE COMMUNITY

The PCBWay website hosts a collection of over five hundred printed circuit projects developed by the user community, accompanied by extensive project documentation and accessible in full compliance with the open source philosophy. An extract of the enormous number of projects carried out can be seen in Figure 3 .

Figure 3: the extensive collection of PCB projects developed by the user community

This result is made possible by an important and commendable sponsorship initiative offered by PCBWay to its customers, applicable exclusively to projects without commercial purposes (no profit). By filling out the sponsorship request form online (in which the customer agrees to share his own non-profit project with the user community) students, makers and hobbyists can easily obtain a coupon for the first order on PCBWay completely free.

CONCLUSIONS

PCBWay is the ideal partner for electronic designers, to whom it can offer a complete range of professional services able to cover all phases of the development cycle of an electronic system. All services, starting with the prototyping and printing of PCBs, are easily accessible online , with delivery times among the lowest ever.

How is a PCB made ?

PCB assembly factories of PCBWay