A new study about “Reduction of overheating of 2D materials” published in the Journal of Advanced Materials. The work put behind the study is credited to the researchers at the University of Illinois at Chicago College of Engineering. By joining together two-dimensional materials used in nanoelectronic devices between their three-dimensional silicon bases, they formed an ultrathin layer of Aluminium Oxide which can significantly reduce the risk of component failure due to overheating.

Modern silicon-based electronic components use 2D materials such as graphene. These materials are formed of a single-atom-thick layer of carbon atoms. They are used into the electronics components which allows them to be several orders of magnitude smaller than if they were made with conventional 3D materials. These 2D materials enable many unique functionalities in those 3D nanostructures. But the main drawback of using this kind of material junction is that they prone to overheat and lose their performance.

In the field of nanoelectronics, the poor heat dissipation of 2D materials has been a bottleneck to fully realizing their potential in enabling the manufacture of ever-smaller electronics while maintaining functionality,

-stated Amin Salehi-Khojin, associate professor of mechanical and industrial engineering in UIC’s College of Engineering.

One of the most important reasons that 2D materials can’t efficiently transfer heat to silicon is that the interactions between the 2D materials and silicon in components are rather weak. Bonds between the 2D materials and the silicon substrate are not very strong, so when heat builds up in the 2D material, it creates hot spots causing overheat and device failure.

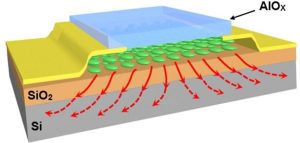

To enhance the connection between the 2D material and the silicon base to improve heat conductance, engineers have experimented with adding an additional ultra-thin layer of material on top of the 2D layer. It creates a “Nano-sandwich” with the silicon base and ultrathin material acting as the “bread”. By adding another ‘encapsulating’ layer on top of the 2D material, they have been able to double the energy transfer between the 2D material and the silicon base.

Read more: Nano-sandwiches in Electronics Significantly Reduce Risk of Overheating