Description

The RTC maintains seconds, minutes, hours, day, date, month, and year information. The date at the end of the month is automatically adjusted for months with fewer than 31 days, including corrections for leap year. The clock operates in either the 24-hour or 12-hour format with an active-low AM/PM indicator. Two programmable time-of-day alarms and a programmable square-wave output are provided. Address and data are transferred serially through an I²C bidirectional bus.

A precision temperature-compensated voltage reference and comparator circuit monitors the status of VCC to detect power failures, to provide a reset output, and to automatically switch to the backup supply when necessary. Additionally, the active-low RST pin is monitored as a pushbutton input for generating a µP reset.

Key Features

- Accuracy ±2ppm from 0°C to +40°C

- Accuracy ±3.5ppm from -40°C to +85°C

- Battery Backup Input for Continuous Timekeeping

- Operating Temperature Ranges

- Commercial: 0°C to +70°C

- Industrial: -40°C to +85°C

- Low-Power Consumption

- Real-Time Clock Counts Seconds, Minutes, Hours, Day, Date, Month, and Year with Leap Year Compensation Valid Up to 2100

- Two Time-of-Day Alarms

- Programmable Square-Wave Output

- Fast (400kHz) I²C Interface

- 3.3V Operation

- Digital Temp Sensor Output: ±3°C Accuracy

- Register for Aging Trim

- Active-Low RST Output/Pushbutton Reset Debounce Input

- Underwriters Laboratories (UL) Recognized

This article explores the significant performance enhancements that MEMS technology enables in accurate real-time clock applications, writes Paul Nunn, senior business manager, Maxim Integrated.

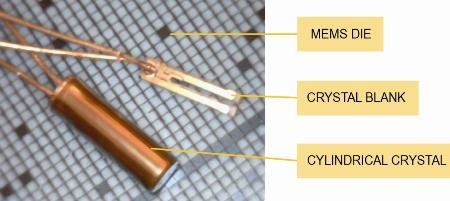

MEMS (microelectromechanical systems) technology has been implemented in accurate real-time clocks (RTCs), making them extremely rugged, highly accurate both over time and temperature, and significantly smaller than clocks built using standard cylindrical crystal technology.

With 47 times less area and 182 times less volume than that of a 32.768kHz tuning-fork cylindrical crystal, the MEMs resonator technology provides a significant advantage in size and packaging options for RTCs today.

This size differential allows for smaller packaging options, provides significantly enhanced ruggedness in high-vibration and shock environments, and demonstrates little to no aging (< ±1ppm total) over the life of the device.

However, the advantages that MEMS brings to this technology do not end with size. There are four distinct areas of technology where MEMS characteristics deliver enhanced technical advantages. These areas include: process and development, assembly and manufacturing, environmental ruggedness, and in-field product performance and service.

MEMS in CMOS Process and Development

Let’s quickly compare a MEMS process with crystal assembly.

The MEMS resonator technology discussed here was developed in standard CMOS fabs. CMOS fabrication is especially advantageous for meeting targeted frequency responses based on the shape and sizes of device elements established at the photolithographic stage of development.

Since MEMS is a silicon technology, the benefits of repeatability and sustainability apply to the manufacturing of MEMS wafers. The manufacturing temperatures reached while processing MEMS wafers can exceed +700°C, but the MEMS resonator can be subjected to multiple reflow temperatures of+260°C without degrading its performance. (We will talk about this in more detail below.) This durability can be attributed to its material makeup, design, and wafer processing flow.

For more read: MEMS are a great fit for real-time clocks