Isabellenhütte has developed a new range of precision resistors in standard sizes with resistances ranging from 1 to 6 mOhm for applications that require small and low-ohmic shunts. In terms of their construction, the components are also less complex than the current ISA-PLAN®resistance families. And yet, they offer the same performance quality: very good long-term stability, a low temperature coefficient, and low thermoelectric voltages.

With the FMx shunt family, Isabellenhütte has now plugged a gap in the standard size range for precision resistances. It has not been possible with the previous product ranges to realize the usual S (2512), P (2010) and K (1206) standard sizes in the resistance range from 5 to 1 mOhm. The impetus for this new development was provided by increasing demand for these resistances as well from a wide range of industries, including the automotive sector (for in-car chargers and assistance systems) and industry (for BLDC drive units), but also from the consumer market (e.g. for white goods).

The Development Approach

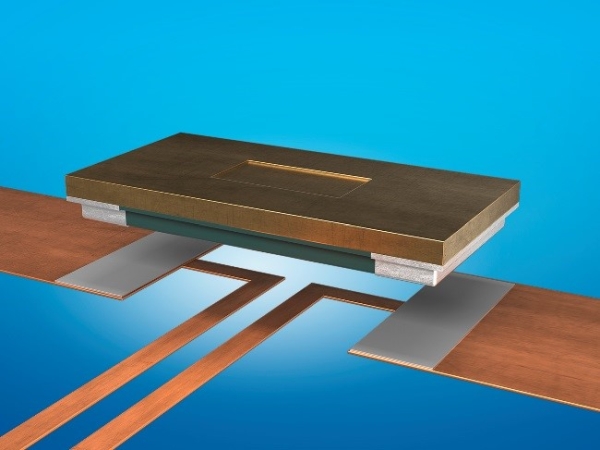

The large cross-sectional areas required for low-ohmic components have been achieved by a change in construction, and the production process has also been significantly simplified. A further milestone for the FMx shunts has been the development of the NOVENTIN® resistance alloy to make it possible to realize these low-ohmic values in defined sizes. Until now, the ISA-PLAN® resistances (SMx, VMx and CMx) have followed a sandwich construction, consisting of a substrate – usually copper – an adhesive and a resistance film made out of the ZERANIN® and MANGANIN® resistance alloys developed in-house by Isabellenhütte. The FM in the title of the new range stands for “Full Metal”, i.e. the components are fashioned in the corresponding thickness out of a full metal plate made of the resistance material in question and directly soldered onto the underside. These variant is very low-ohmic due to the large cross-sectional areas. 1 mOhm is realized with the ZERANIN® alloy, 2 mOhm with MANGANIN®, and, for the first time, NOVENTIN® is being used in ISA-PLAN® products for the resistance range from 3 to 6 mOhm. The new design has given rise to a particularly robust construction which also makes it possible to leave out some work stages and reduce costs. An important point for the automotive industry is this: The components form a soldering point meniscus to guarantee the possibility of automated inspection of the soldering points.