Summary of IoT Based Smart Mine Safety System Using Arduino

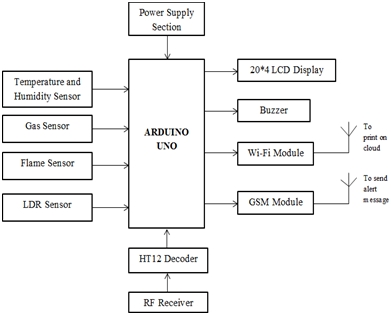

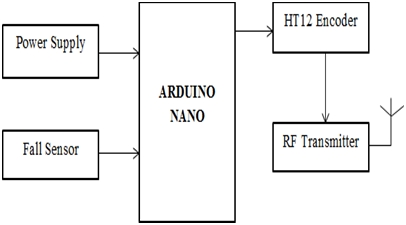

This article discusses a mining safety monitoring system leveraging IoT and Arduino technologies to address hazardous working conditions. The system utilizes various environmental sensors connected to Arduino microcontrollers for centralized data collection, transmitting data via WiFi or GSM to cloud servers for real-time monitoring and emergency alerts. The implementation involves programming, robust hardware design, and software development, including mobile and web interfaces. The solution aims to proactively enhance mining safety, reduce accidents, and provide data-driven operational insights, representing a significant technological advancement in mining safety management.

Parts used in the Mining Safety Monitoring System:

- Various Environmental Sensors (e.g., temperature, gas level sensors)

- Arduino Microcontrollers

- WiFi Module

- GSM Module

- Enclosures for harsh environment protection

- Circuitry components for sensor interfacing

- Firmware for Arduino

- Server-side software for data storage and analysis

- Mobile/Web Application interfaces

Significance

- Addresses critical safety concerns in mining which is inherently hazardous work

Leverages IoT and Arduino to develop a comprehensive safety monitoring system

Has potential to significantly reduce accidents and improve standards if implemented widely

Methodology

- Utilizes various sensors to monitor environmental parameters like temperature, gas levels etc

Interfaces sensors with Arduino microcontrollers for centralized data collection and processing

Transmits processed data to cloud/server using IoT protocols like WiFi, GSM for remote access

Likely includes development of interfaces for real-time visualization and emergency alerts

Implementation

- Requires programming Arduinos to interface with and read data from deployed sensors

Design of circuitry and enclosures to withstand harsh mining conditions

Firmware development for Arduinos and server-side software for data storage, analysis, interfaces

Mobile/web apps may be created for remote access by miners and supervisors

Potential Impact

- Facilitates proactive safety management through real-time monitoring of conditions and hazards

Can reduce accidents, injuries, fatalities through early warnings of issues

Leads to improved reputation and cost savings from less downtime and regulatory penalties

Provides data driven insights for better resource planning, maintenance and emergency response

Conclusion

- Represents an innovative application of technologies for pressing need of mine safety

Has potential to transform practices but requires further refinement and adoption

Overall a commendable effort towards developing a comprehensive networked safety solution

Continued R&D in this area is warranted to fully realize benefits across mining operations.