Computed tomography (CT) or computed axial tomography (CAT) is most often associated with imaging the body because it enables clinicians to see the anatomical structure inside the patient without having to do any surgery. To image inside the human body, a CT scanner requires X-rays because the radiation has to be able to penetrate through the body. If the object is semi-transparent, it is actually possible to conduct CT scanning using visible light! The technique is called optical CT, which is different than the more popular optical imaging technique known as optical coherence tomography.

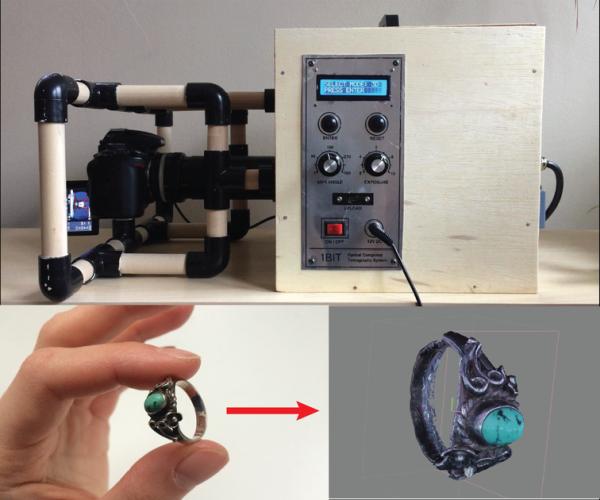

To acquire 3D scans of semi-transparent objects, I constructed an optical CT scanner using an Arduino Nano and Nikon dSLR. Halfway through the project, I realized that photogrammetry, another 3D scanning technique, requires much of the same hardware as an optical CT scanner. In this instructable, I will go over the system I constructed that is capable of CT scanning and photogrammetry. After acquiring images, I have steps on using PhotoScan or Matlab for computing 3D reconstructions.

For a full class on 3D scanning, you can check out the instructables class here.

I recently found out about Ben Krasnow built an x-ray CT machine with an Arduino. Impressive!

After posting, Michalis Orfanakis shared his homebuilt optical CT scanner, for which he won the 1st prize in Science on Stage Europe 2017! Read the comments below for full documentation on his build.

Resources on optical CT:

The history and principles of optical computed tomography for scanning 3-D radiation dosimeters by S J Doran and N Krstaji

Three-dimensional image reconstruction for CCDcamera based Optical Computed Tomography Scanner by Hannah Mary Thomas T, Student Member, IEEE, D Devakumar, Paul B Ravindran

Focusing optics of a parallel beam CCD optical tomography apparatus for 3D radiation gel dosimetry by Nikola Krstaji´c and Simon J Doran

Step 1: Computed Tomography and Photogrammetry Background

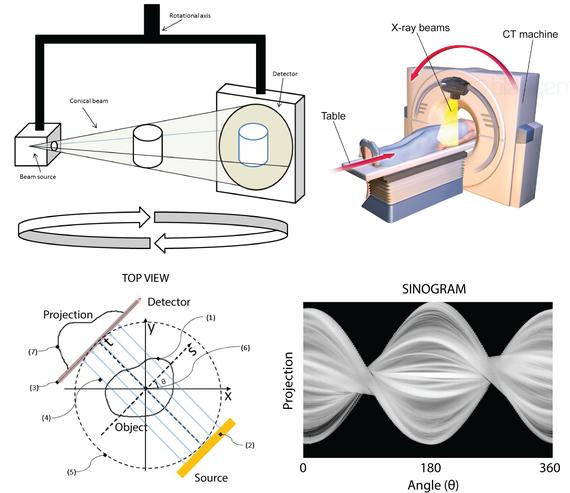

CT scanning requires a source of radiation (e.g. x-rays or light) on one side of an object and detectors on the other side. The amount of radiation that makes it to the detector depends on how absorptive the object is at a particular location. A single image acquired with this setup alone is what produces an X-ray. An X-ray is like a shadow, and has all the 3D information projected into a single 2D image. To make 3D reconstructions, a CT scanner acquires X-ray scans over many angles by either rotating the object or the source-detector array.

The images collected by a CT scanner are called sinograms, and they display absorption of X-rays through one slice of the body vs. angle. Using this data, a cross section of the object can be acquired by using a mathematical operation called the inverse Radon transform. For full details on how this operation works, check out this video.

The same principle is applied for the optical CT scanner with a camera acting as the detector and the LED array acting as the source. One of the important parts of the design is that the light rays that are collected by the lens are parallel when travelling through the object. In other words, the lens should be telecentric.

Photogrammetry requires the object to be illuminated from the front. Light is reflected off the object and is collected by the camera. Multiple views can be used to create a 3D mapping of the surface of an object in space.

While photogrammetry enables surface profiling of an object, CT scanning enables the reconstruction of the internal structure of objects. The major disadvantage for optical CT is that you can only use objects that are semi-transparent for the imaging (e.g. fruits, tissue paper, gummie bears, etc.), whereas photogrammetry can work for most objects. Furthermore, there is much more advanced software for photogrammetry so the reconstructions look incredible.

Step 2: System Overview

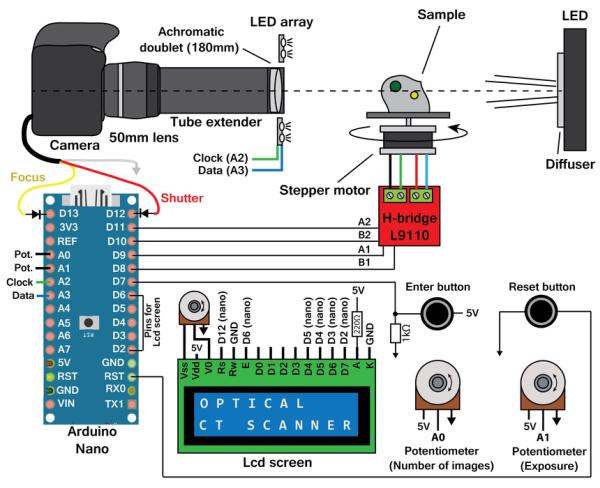

I used a Nikon D5000 with a 50mm focal length f/1.4 lens for imaging with the scanner. To achieve telecentric imaging, I used a 180mm achromatic doublet separated from the 50mm lens with a tube extender. The lens was stopped down to f/11 or f/16 to increase the depth of field.

The camera was controlled using a shutter remote that connects the camera to an Arduino Nano. The camera is mounted to a PVC structure that connects to a black box that holds the object to be scanned and electronics.

For CT scanning, the object is illuminated from the back with a high-power LED array. The amount of light collected by the camera depends on how much is absorbed by the object. For 3D scanning, the object is illuminated from the front using an addressable LED array that is controlled with the Arduino. The object is rotated using a stepper motor, which is controlled using an H-bridge (L9110) and the Arduino.

To adjust the parameters of the scan, I designed the scanner with an Lcd screen, two potentiometers, and two push buttons. The potentiometers are used to control the number of photos in the scan and the exposure time, and the push buttons function as an “enter” button and a “reset” button. The Lcd screen displays options for the scan, and then the current status of the scan once acquisition begins.

After positioning the sample for a CT or 3D scan, the scanner automatically controls the camera, LEDs, and Motor to acquire all the images. The images are then used for reconstructing a 3D model of the object using Matlab or PhotoScan.

Step 3: Supply List

Electronics:

- Arduino Nano

- Stepper motor (3.5V, 1A)

- H-bridge L9110

- 16×2 Lcd screen

- 3X 10k potentiometers

- 2X pushbuttons

- 220ohm resistor

- 1kohm resistor

- 12V 3A power supply

- Buck converter

- Power jack female

- Power barrel plug

- Micro USB extension cable

- Power switch

- Potentiometer knobs

- PCB standoffs

- Prototype board

- Wire wrap wire

- Electrical tape

Camera and lighting:

- A camera, I used a Nikon D5000 dSLR

- Prime lens (focal length = 50mm)

- Tube extender

- Achromatic doublet (focal length = 180mm)

- Shutter remote

- Addressable LED strip

- Utilitech pro 1-lumen LED portable light

- Paper for diffusing light

Light box:

- 2x 26cmx26cm ¼ inch thick plywood

- 2x 30cmx26cm ¼ inch thick plywood

- 1x 30cmx25cm ½ inch thick plywood

- 2x ½ inch diameter dowel rods

- 8x L-shaped PVC joints ½ inch diameter

- 8x T-shaped PVC joints ½ inch diameter

- 1x PVC cape ½ inch diameter

- 4feet 1×2 pine

- Thin aluminum sheet

- Black poster board

- Nuts and bolts

- Spring

Tools:

- Soldering iron

- Power drill

- Wire wrap tool

- Dremel

- Jigsaw

- Wire cutters

- Scissors

- Tape

Step 4: Box Design and 3D Mounts

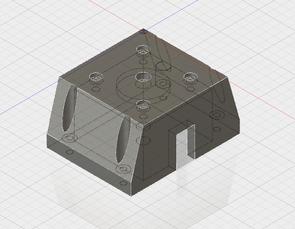

I designed the camera mount and box using Fusion360. The PVC pipe portion of the design was inspired by DIY steadicam jigs that are used to stabilize cameras for video. The box had to block out light from the surroundings, and provide precise alignment of the sample and the camera. To mount several of the components, I also designed several custom parts in Fusion and 3D printed them. Here is a list of the parts that I printed.

3x Dowel rod mounts to connect the camera to the black box

2x LED module mounts to connect the LED to the black box

1x Stepper motor mount

1x Object stage that connects to motor shaft

1x Object spear that connects to motor shaft

1x Handle for black box lid

2x Cable mount for fixing the LED power cable and camera remote to the light box

Once these parts are printed, you will be able to assemble the rest of the scanner. I have provided .stl files for download in this step.

Step 5: PVC Camera Mount Assembly

The PVC joints were painted black. To achieve a homogenous black, I used about five coats of black. Try your best to not get paint in the joints.

After painting, I assembled the jig for holding the camera described in this video. A hole is drilled in the bottom of one of T-joints and PVC cap. A 2 ½ inch bolt is pushed through the T-joint A spring is placed around the bolt and two nuts are used to put the spring in slight tension.

The dowels were then cut as follows using a jigsaw and wood saw:

- 1X 17cm

- 2X 14cm

- 4X 9cm

- 8X 5.5cm

- 4X 5cm

- 2X 3.2cm

After cutting the dowels, they were inserted into the PVC joints. Unfortunately, they were a much tighter fit than I expected! I had to sand down the dowels and hammer them into the joints.

Step 6: Construct Light Box

Next I built up the box using plywood and 1×2 planks. The sides were nailed into the planks, and holes were cut for the camera, LED array, and front panel. After the box was assembled, the dowel rod mounts were attached to it so that they aligned with the camera mount. The LED was also mounted using the 3D printed mounts.

To power the LED, I connected a 2.1mm x 5.5mm barrel plug into the back and ran the cable into the box. The cable was held in place using 3D printed plugs. In addition to the plug for the LED power, the remote cable also must go through the box to connect the camera trigger to the prototype board.

Finally, I created a lid for the box. The 3D printed handle was attached using two bolts.

Source: Desktop CT and 3D Scanner With Arduino