To create a PCB with 3Drag , by milling , it is necessary to have the G-Code files for the tracks patterning and for the holes relating to the printed circuit board itself. In this section we describe how to obtain these G-Code files using a specific plugin for the popular PCB design software ” EAGLE “.

Note: This operation can be done only if the PCB you want was created with EAGLE .

The PCB- gcode plugin allows to create the G-code files for patterning the top copper tracks, bottom copper and also that relating to the drilling of the base created with the freeware program EAGLE . It also allows to define the extension of the file that must be exported ( .nc) so that it is compatible with Repetier -Host.

In succession we described here the procedure to create a simple single-sided PCB by milling incision.

– The first operation is to download the software EAGLE from CadSoft download by choosing the version for your operating system.

– Carry out EAGLE freeware installation launching the .exe file

– Download the PCB – gcode (version taken into consideration: 3.6.0.4 ) from this web site (you must have a YAHOO account) or download from the dedicated forums .

– Unzip the folder and then copy the files in the ULP folder of EAGLE.

– Start EAGLE, click on File/Open/Board and select the file of the PCB that you want to create by milling .

Mirror the printed circuit board and align the lower left corner of the base with the starting point of the worksheet . This operation is to keep the PCB in the work plan and to orient the PCB so that the copper side to work (called “Bottom Copper” ) is facing upwards.

Note: It is recommended to set a unique value for the central hole of all the plots in order to use a single drill bit .

PCB- gcode parameters configuration

– Start PCB- gcode typing this command in the command line: run pcb- gcode -setup

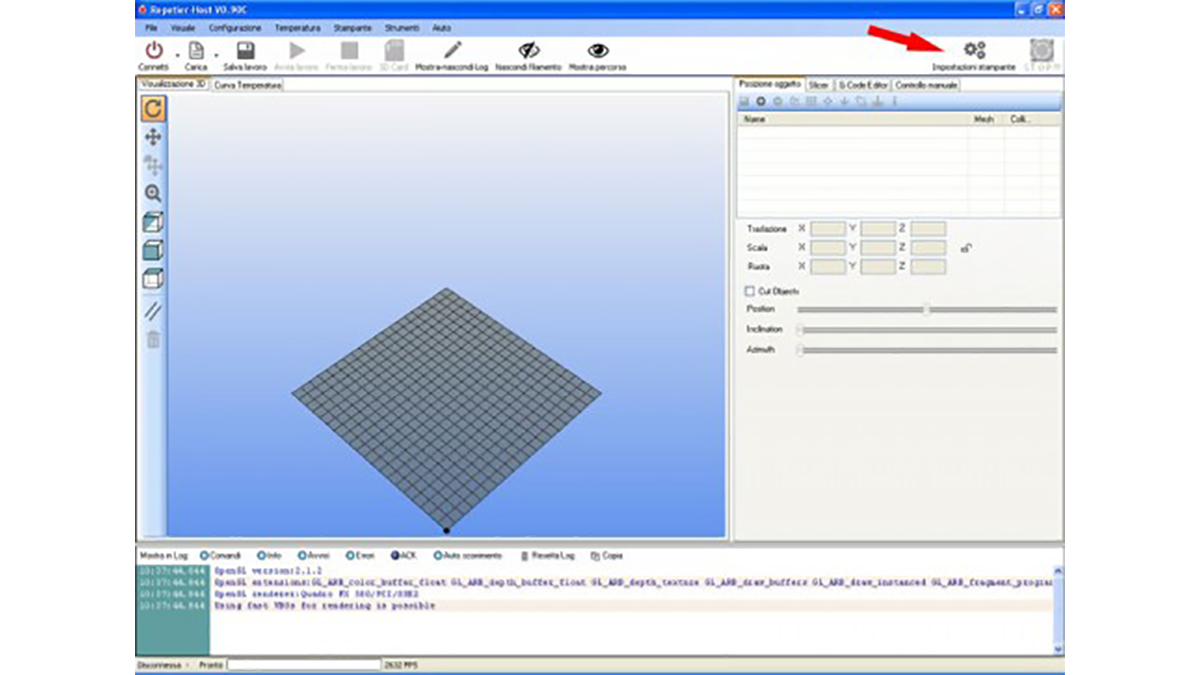

After sending it you will see the following window in which you have several configuration folders (Generation Options , Machine, GCode Style, GCode options ….) :

In the “Generation Options” folder check the two entries under “Top Side” and the entry Single pass of “Isolation” . This allows to make tracks patterning with a single pass of the tool.

Set a value for the minimum insulation (Minimum ) and the size of the milling tool bit used (Etching Tool Size) , for example 0.2 mm .

Note: the unit “mm ” must be set in the “Machine” sheet.

In the “Machine” folder you have to set, in addition to the unit of measurement (mm , Mils , etc …), the parameters related to the machine advancement or the ” Feed Rates” (300 mm / min for X and Y and 100 mm / min for Z ) , positioning of the Z …

Z High: maximum lifting of Z (e.g. 5 mm);

Z Up: lifting of the Z while moving from one point to another (e.g. 0.8 mm);

Z Down: incision depth (e.g. 0.1 mm) ;

Drill Depth (e.g. 1.8 mm, depending on the base thickness);

Drill Dwell: waiting time before the rise of the drill bit (e.g. 0.5 s)

The position for the tool change (no bit change is done) and other parameters not taken into account for the PCB construction.

Read more: Creating G-Code via EAGLE software