Week 01

January 9, 2013 (1 hour):

Meet as a team after class to discuss preliminary project proposal. It is decided that we are going to build up a vehicle like a Google street car.

January 10, 2013 (2 hours):

Met as a team after class to finish writing preliminary project proposal. First version of PSSC is confirmed.

WEEK 01 SUMMARY

Accomplishments: Submitted preliminary project proposal.

Weekly Work Total: 3 hours

Project Work Total: 3 hours

Week 02

January 14, 2013 (2 hours):

Using HTML to actually building up the website,

Finishing final proposal of the 477 project.

WEEK 02 SUMMARY

Accomplishments: Final proposal

Weekly Work Total: 4 hours

Project Work Total: 7 hours

Week 03

January 23, 2013 (2 hours):

PPT for the first PSSC presentation

January 24, 2013 (1.5 hours):

PCB homework is done.

January 27, 2013 (2 hours):

Preliminary Parts discussion with Xirong Ye and Zongyang Zhu. Settings up Google Drive Excel file for parts review.

WEEK 03 SUMMARY

Accomplishments: PCB homework and Preliminary parts review

Weekly Work Total: 5.5 hours

Project Work Total: 12.5 hours

Week 04

January 28, 2013 (3 hours):

Complete the PCB homework, finished the preliminary part list and finished a preliminary budget calculation, which is within the rage of 300 dollars.

January 29, 2013 (3 hours):

Browsing parts for the design constrain homework. Searching for compatible parts in a way that fit into the power, size I/O pin and budget constrain.

January 30, 2013 (6 hours):

Complete the design constrain homework and send it to each team member for review purpose. List a copy of the parts and let Chun-da to fill in the Parts Order Form (GPS,GPS antenna, Ultrasonic sensor, Raspberry Pi, Camera). Ordered the free sample (NXC LPC1768 and PIC32).

WEEK 04 SUMMARY

Accomplishments: Design constrains homework, Part-searching.

Weekly Work Total: 12 hours

Project Work Total: 24.5 hours

Week 05

February 4, 2013 (2 hours):

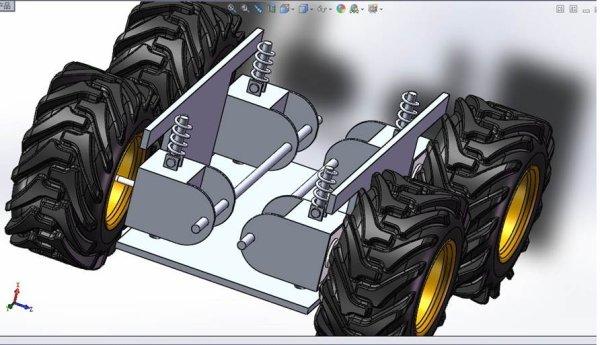

Searching for a suitable chassis online and meeting with team-mates. Vote for the best solution of the chassis which is to design and manufacture the chassis on ourselves. I am mainly responsible for the design and other team member will give ideas to support. Start to self-study Solid works software.

February 7, 2013 (3 hours):

Help Chun-da to finish packaging homework by design a preliminary model of the chassis.

WEEK 05 SUMMARY

Accomplishments: Packaging design and Preliminary 3D design of the chassis

Weekly Work Total: 5 hours

Project Work Total: 29.5 hours

Week 06

February 11, 2013 (1 hour):

Spend some time to imagine that what kind of user interface is best suitable. For example, a route map with 360 picture represent as a dot on the route will be an ideal user interface tab since it is just like what Google do in the Google map. But in order to achieve that the motor and the ultrasonic sensors data have to be recorded well to present an accuracy route.

February 12, 2013 (3 hours):

Actually design preliminary chassis for the chassis on solid works software. A chassis body is designed to have a box of dimension 30*20*15 cm, made up from aluminum plate of thickness 2mm and punched with M3 size holes, 10mm away from each other. The holes are for ventilation and mounting of PCB and parts.

February 13, 2013 (3 hours):

Researched for 1 hour for what is it like for a modern car chassis and how to apply it to the car chassis for the car I am designed. Talk to the EE machine shop supervisor Chuck Harrington to discuss the technical specification of the possible cost of the vehicle. Decide the motor (http://www.applied-motion.com/products/stepper-motors/ts2170n1001e95) for the vehicle and the H Bridge. I have drawn a sketch of the suspension system since it seems important if the chassis is facing uneven floor.

February 15, 2013 (3 hours):

Finally finished the chassis design (dimensions are shown in mm):

1 Front view

2 Side view

3 Top view

4 Exploded view (In here you can see that the motor is pushed into the motor housing and directly driving the wheel since the step motor has low/high torque mode to serve as gear box itself)

Close look to the suspension mechanism (it can be seen that the suspension is served as a simple lever system. The 2 long bolts in the middle which went through the holes on front and back cover is the fulcrum of the lever, the force applied to the wheel from the floor to straight up and the force generated by the spring from up to down is the 2 forces on the lever. The bolt on the motor housing is nut on the top panel in case that when the car is lifted, the wheel and spring is staying connected.

Whole chassis (a complete chassis weight 1.2 kg from aluminum).

February 16, 2013 (2 hours):

My teammates reject the chassis design due to following reasons at the meeting:

1.The chassis suspension system is not necessary since it can be compensated by using foam and plastic wheel. A suspension system is heavy and consumes a lot of interior space of the vehicle.

2. The step motor to drive the chassis is not considered powerful enough since 4 of the step motor only generate 1.5kg drag force. With a heavy chassis and the high power consume motor it is not feasible.

Instead of manufacture of our own chassis, we have ordered Dagu 4wd thumper online.

A change of chassis design has also affect the power system of the whole project:

The new Dagu thumper need 7.2V sub-c battery, which means that the project need 3 voltage level: 3.3v for GPS, 5v for USB device(WIFI and Raspberry Pi, ultrasonic), 7.2V for the motors.

The team meeting has decided the new step down regulator and fuel gauge/power management IC specifically for the current system. NiCdbattery has chosen since it has no memory effect and can provide high power.

WEEK 06 SUMMARY

Accomplishments: Finished the chassis design, chassis parts rationale, User interface discussion

Weekly Work Total: 10 hours

Project Work Total: 39.5 hours

Week 07

February 18, 2013 (2 hour):

Drawn a PCB pin out of the LPC 1768 for the PCB design according to the mbed references.

Symbol

Packaging

library download

February 19, 2013 (3 hours):

GPS prototyping is finished, The GPS module is maestro A-2200A. It supports GPIO, I2C and Serial output (Uart). As a standard way of prototyping, an Mbed LPC 1768 is used to function as a “pass through” between the GPS module and the computer serial port. The GPS output is standard NMEA 2000 style that output serial character from Uart using baud rate 4800. The Mbed receive the GPS NMEA data and then send the data to the PC at the same baud rate and then PC output the data by Tera term terminal.

The active Antenna is Tee biased in the set up for the GPS and antenna:

This is a typical Tee biased antenna set-up. The ac signal and dc power supply share the positive end of the antenna. In order to prevent conflict of the power and the signal, the set-up uses a capacitor to eliminate the dc signal of the power and the inductor to eliminate the ac satellite signal. The value chosen can be calculated by the following way:

![]()

In here the GPS frequency is 1575.42 MHz, the value of the capacitor and inductor cannot go below the nominal value on the diagram.

February 20, 2013 ( 4 hours):

LPC 1768 soldering: Trying to solder 100 pin LPC 1768 microcontroller in the break out board at and soldering the power and de-coupling capacitor.

GPS field test: GPS field test is successful at a open area, once the GPS signal is synced, the GPS immediately transfer ASCII code to the microcontroller and the microcontroller will transfer the ASCII sentence to PC via tera term. The GPS sentence is complied with NMEA format.

For example:

$GPGLL,3751.65,S,14507.36,E*77

$GPGLL,4916.45,N,12311.12,W,225444,A

4916.46,N Latitude 49 deg. 16.45 min. North

12311.12,W Longitude 123 deg. 11.12 min. West

225444 Fix taken at 22:54:44 UTC

A: Data valid

February 23, 2013 ( 3 hours):

Mbed dead: The mbed is broken during the test yesterday. Since the Mbed has a tight fit in the breadboard, tools are required to remove mbed from the board, the mbed lost a connection on trace. Zongyang has detected the problem and soldered the trace to recover the Mbed

Ultrasonic: Ultrasonic recieved a trigger and starting to transmit the ultrasonic pulse, when transmitting is complete, the ultrasonic will raise the echo to high and if there is a feed back , the echo will back to low. This mechanism has been tested on the oscilloscope.

WEEK 07 SUMMARY

Accomplishments: Library, GPS prototype, Ultrasonic testing.

Weekly Work Total: 12 hours

Project Work Total: 50.5 hours

Week 08

February 25, 2013 (6 hour):

Meeting : power, prototype The group had a meeting to discuss the final power supply parts for the project, for 3.3V power output we will use LTC3633A and for 5V we will use TPS62052. 5V power supply will bearing more burden since it will drive Raspberry PI. For 3.3V 0.5A is required, and 5V 1.3A is required.

Mbed flash lpc1768: To flash LPC1768, The following sequence has to be followed. Starting the MCU with the Rest pin pulled high, this will make sure that the MCU entering the ISP mode and receives binary code. Since the Mbed project has a open source library we can incorporate the library to speed up prototyping. But currently ISP flashing is experiencing issues that the microcontroller cannot be connected yet.

February 26, 2013 ( 2 hour):

Search for servo: A servo motor is needed for the 360 degree camera to rotate, this camera has to have a rotation degree of 360 degree which is wider than normal servo motor. Sparkfun has middle servo that is 360 degree and provide a relatively low torque which is enough for the camera.

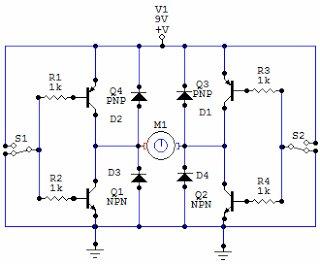

h-bridge: H bridge sample has arrived, It is L298N that has 2 full bridge. Each of the full bridge has 2A current limit.

March 3, 2013 ( 3 hour):

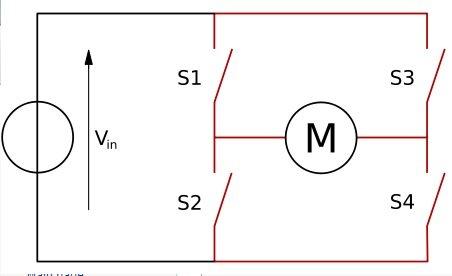

PWM module and H-bridge tested: A PWM signal is generated in Mbed and is used to driven the H-bridge and drive the Chassis motor for one side. Only half of the bridge is used. Sot the motor will only travel in one direction. A preliminary design of the PWM control can be:

In here there are 3 mode can be implement in this h bridge

1. Forward by closing s1 and s4

2. backwards by closing s3 and s2

3. electronic braking by closing s1 and s3 (if the two terminal of the motor is shorted, especially for a brush motor, it will create a braking effect.

WEEK 08 SUMMARY

Accomplishments: H-bridge testing, PWM , ISP mode

Weekly Work Total: 11 hours

Project Work Total: 61.5 hours

Week 09

March 4, 2013 ( 1 hour):

prepare for the formal presentation, printing Schematic and PCB

WEEK 09 SUMMARY

Accomplishments: team presentation

Weekly Work Total: 1 hours

Project Work Total: 62.5 hours

Week 10

March 4, 2013 ( 1 hour):

presentation week

March 8, 2013 ( 2 hours):

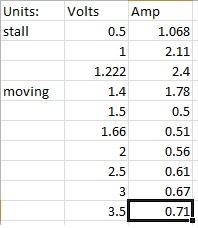

Vehicle test, stall current:

For more detail: Build up a vehicle