In this post, we will briefly discuss how a Typewriter-Turned-Plotter:

Apologies for the poorly written instructable. I don’t have much time these days and was not thinking of writing one when I was working on the project.

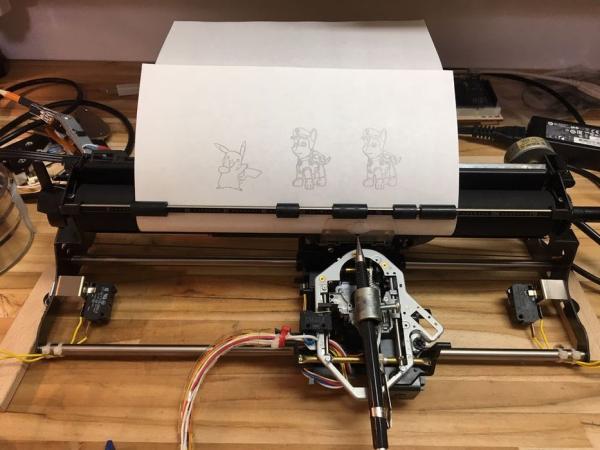

A few months ago I made a CD ROM plotter for my daughters. See attached a couple of pictures (the one with a bunch of small cartoons and the one with the blue pen). I borrowed the idea and files from other Instructables and there is nothing special about it so I did not do a write-up. My 3 yo loves it but the 8 you said it was boring because it was too small. So I decided to build something bigger but did not want to build a CNC from scratch, because of time and $.

I then found a very cheap and heavily used simple Smith Corona typewriter and decided it was going to be the base for this building as it has pretty much all I need – precise movement in two directions, using stepper motors.

I did not find anything close to this anywhere, if you find something, let me know as I want to get ideas on how to improve it. Here it goes.

Disclaimer: No good and working typewriter was harmed in the making of this project – The guinea pig was at the very end of its life before I pulled it apart.

Typewriter Turned Plotter Steps – 1: Choose a Typewriter

Any electronic typewriter will do, I chose a Smith Corona with stepper motors for paper feed, carriage, and daisywheel movement. I first opened an old Olivetti and found DC motors and optical encoders. Because I am running GRBL on Arduino, I needed steppers. There may be CNC software that allows the use of DC motors but I do not know of any.

Step 2: Carriage Resolution

After I had it all done I realized the carriage did not have enough resolution for nice drawings. The mechanism was designed to move in large steps, i.e., when typing. I almost gave up as I had no idea how to solve this problem.

Then I found a small tin can stepper with reduction gear I took from an old scanner. I do not have pictures but what I did was to take the pinion from the original motor and glue to the output gear of the scanner assembly, in effect I just added some reduction gears to the thing.

The tin can steppers on my typewriter is a 7.5 Deg, 48 steps per revolution, not enough for smooth drawing.

The paper feed, however, did not need any mods, it was moving very smooth.

Step 3: Software and Hardware

- I am a beginner so I keep things simple.

- Here is what I use:

- Arduino UNO running standard GRBL (version 1,1g I think).

- CNC shield with A4988 motor drivers.

- A 12V power supply

- Universal G-code Sender (UGS) Platform running on a PC.

- Added some limit switches for safety and to be able to home the machine.

- The last picture shows the GRBL settings I entered/updated via UGS.