Be sure to check out my new instructable , the ‘little Tank’! Really nice tracked design complete with cut files!

update: I’ve had so much response on this instructable, thanks to all. If you end up making one, please let me know! I’d love to put your work on my website!

New new update – The Electric Turtle is going to the 2011 Makers Faire in New York with the LMR (lets Make Robots) exhibit!!!

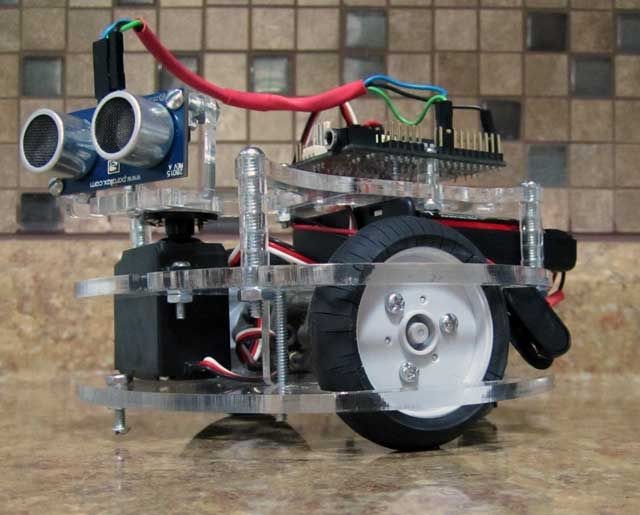

5″ robotic platform, setup for Picaxe or Arduino with sonar ranging mast. This one currently does obstacle avoidance. 90 degree radian etched into the top plate to make turn calibration far easier.

Many battery configurations possible, including lipo (with a regulator) – the deck is spaced to accommodate a large range of power sources.

Designed and made in response to the poorly made/designed commercial offerings – this thing uses I-Beam construction – you can stand on it.

Nice platform to pickup and run with, applicable to many configurations and adaptable to multiple purposes.

Offset ranging mast is provided with cutouts for the ping (what I had on hand), but I put placement holes for several popular models on there as well – tried to make it as universal as possible. Standard IR sensors should fit if you choose to go that route.

Motor configuration is for a Tamiya 70097 motor/gearbox combo – placement holes are in the chassis for either the high or low ratio build configuration of the gearbox. Wheels are Tamiya 70145’s.

Capability to use standard servo or micro servo with adapter plate (included).

Here are laser cut parts kits if you’d rather not cut your own –

Lets make robots! is an excellent resource for DIY robotics as well.

Step 1: Cut your parts

Step 2: Gather your materials

2. qty 4 1.25″ #6-32 screws (hardware store)

3. qty 2 .75″ #4-40 screws (hardware store)

4. qty 4 2″ #6-32 screws (hardware store)

5. qty 4 .5″ #4-40 screws (hardware store)

6. qty 1 servo (standard or micro, standard recommended) and hardware pack that comes with the servo

7. qty 1 sonar or IR (PING used, others may be substituted)

8. qty 1 pair of Tamiya 70145 tires

9. qty1 Tamiya 70097 motor/gearbox

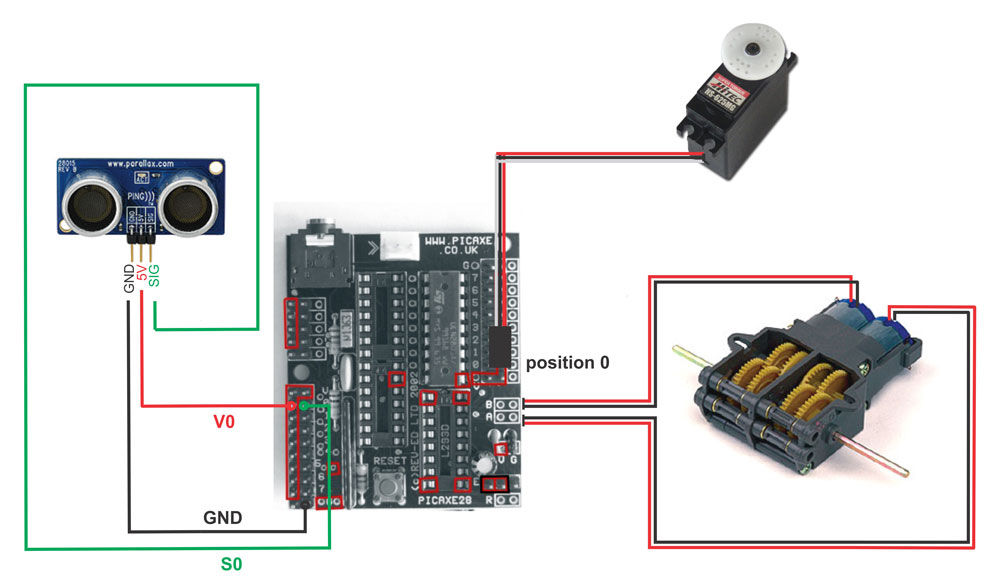

10. qty 1 Arduino, Picaxe or other microcontroller – this instructable uses the Picaxe 28×1

11. Wires, connectors, heat shrink

If you’d like to keep the soldering to a minimum, just use male-male servo extensions for all of the hookups. This will limit your soldering to the 2 connections on each motor. The motors can also be connected with crimp connectors to eliminate all soldering, but I advise a hard soldered connection to the motors in any case.

Soldering iron, multimeter, screwdrivers, etc…

Standard disclaimer about not cutting your fingers off or sticking a hot iron in your nose..

Step 3: Wiring diagram / code for Picaxe

Step 4: Assemble your robot!

Step 5: Servo / upper deck

Step 6: Carrier Board / microcontroller

Step 7: Lower deck / servo risers / motor

Attach the motor, risers and wheels as a unit to the lower deck. Use the screws and nuts that came with your motor for this step. Also install the fore / aft anti-tip screws and nuts at this time. Use 2 .5″ screws + nuts.

For more detail: Electric Turtle Robot