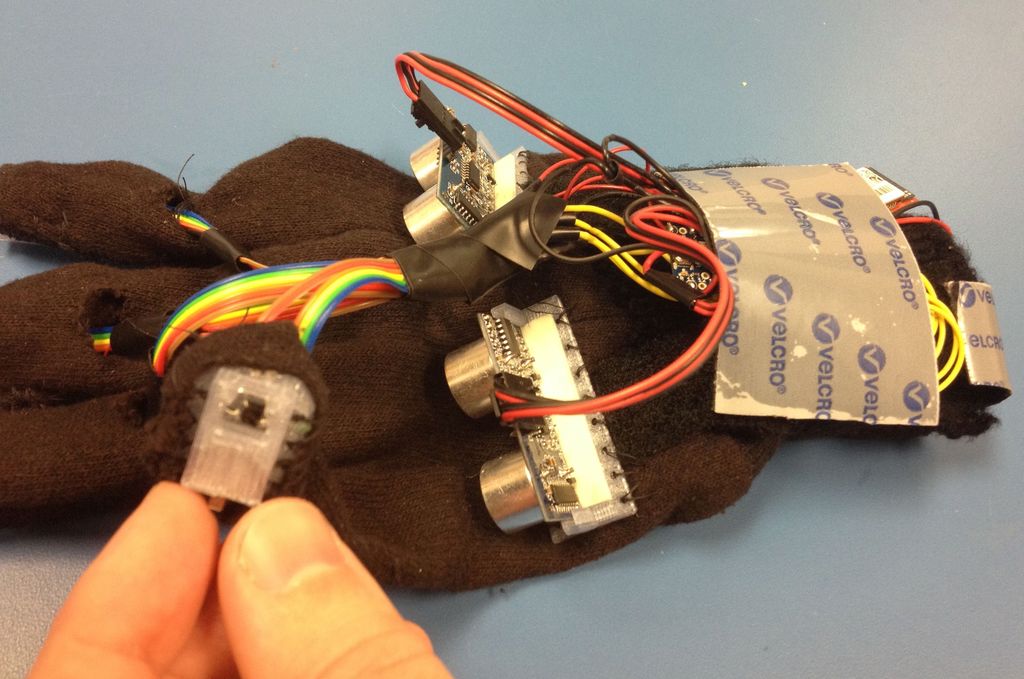

HandSight is a prototype glove to aid the blind. It can sense the lightness or darkness of a surface with tactile feedback from a vibration motor for each individual finger. It can also sense distance from physical objects or obstructions and indicate direction and distance with the same vibration feedback. It supports additional modes, and the possibilities are nearly endless. The glove can connect over Bluetooth to switch modes and visualize the sensor readings.

This instructable was made as part of the final project requirement in the CS graduate course “Tangible Interactive Computing” at the University of Maryland, College Park taught by Professor Jon Froehlich. The course focused on exploring the materiality of interactive computing and, in the words of Hiroshii Ishii, sought to “seamlessly couple the dual worlds of bits and atoms.” Please see http://cmsc838f-f12.wikispaces.com/ for more details.

See our Wiki class page for the project here (where we talk about some of our challenges and limitations):

http://cmsc838f-f12.wikispaces.com/HandSigh

Step 1: List of Materials

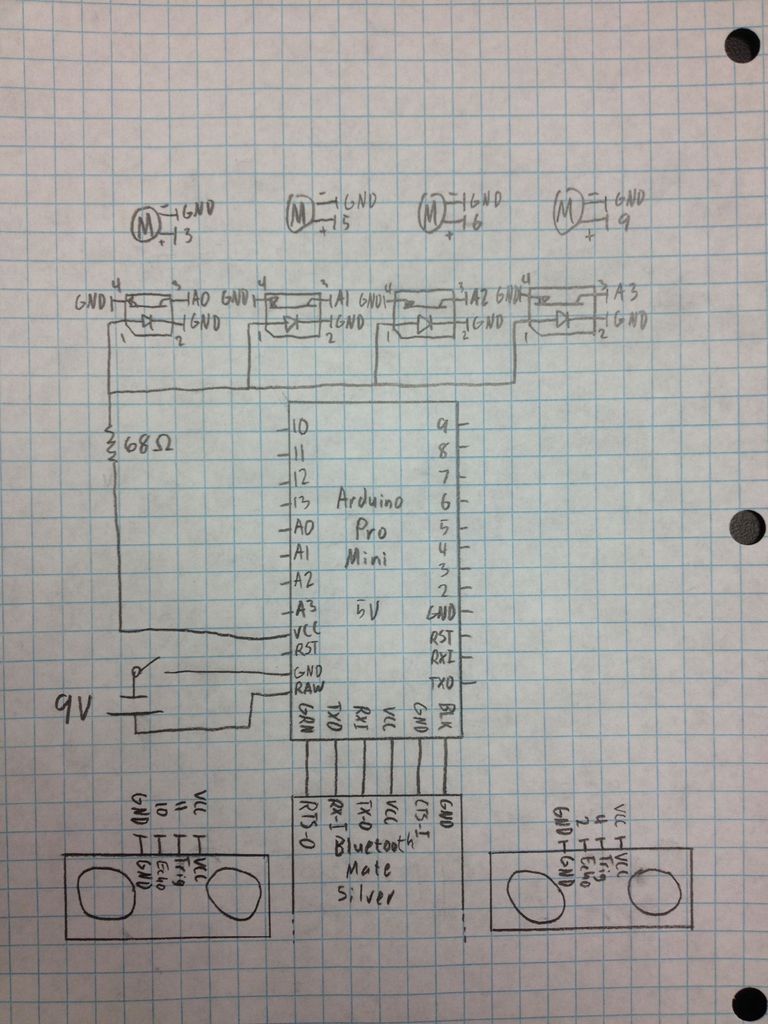

– IR Reflectance Sensor – QRE1113 (x4)

– Vibration Motor ROB-08449 (x4)

– Ultrasonic Range Finder (x2) http://www.amazon.com/Ultrasonic-Module-HC-SR04-Distance-Arduino/dp/B004U8TOE6/ref=sr_1_1?ie=UTF8&qid=1355861471&sr=8-1&keywords=Ultrasonic+Range+Finder

– Bluetooth Mate Silver WRL-10393 (x1)

– 68 ohm Resistor (x1)

– 9v Battery and Battery Case with Switch (x1)

– FTDI cable (for programming) (x1)

– Double Sided Sticky Tape, or other adhesive to hold the ultrasonic sensors in place

– Wire, electrical tape, and soldering materials. Rainbow ribbon cable is recommended for easy wiring of the fingertip sensors.

– Glove that you don’t mind repurposing permanently

– Extra cloth that matches the glove

– Velcro, Sewing Materials

– Windows Phone to run our visualization and control app, or any device that supports the Bluetooth Serial Port Protocol (SPP) if you want to develop your own appAll electronic components available on sparkfun unless otherwise noted

Step 2: 3D Printing

http://www.thingiverse.com/thing:38134We printed with MakerBot Replicator 2. Download STL files, open in a program called ReplicatorG. Put on platform/center. Generate Gcode.Material PLA

Settings used:

infill% 10

layer height 0.27 mm

number of shells 1

feedrate 41 m/s

travel feedrate 56

print temp 226

plastic diameter 1.75 mm

extruder nozzle diameter 0.4mm

(in the actual gcode we changed platform temp to 060, which worked well for PLA)

Print four sets of the fingertip case, and two of the ultrasonic slot.