Responsive Pneumatic Envelop (A useless machine) Mockingly inspired by the blowfish, Bounce Back builds on state of the art bubble wrap shipping envelops by only inflating its bubbles when frightened by rough handling. Inversely, when the package is not being shuck, it will not inflate itself.

Creators: Christian Gotthilf Steixner, Ayşe Esin Durmaz

Bounce Back! “Track your package and the way its handled”

Supplies

Silicone skin (Alternate to Vinyl) supplies:

Ecoflex 0030 Silicone

Silicone Tubing for Air Pumps and Valves – 3mm

T-Connector For Silicone Tubing

Acrylic sheets

Acrylic glue

Access to laser cutter

Gloves

Stir

Mixing Cups

Access to CAD software to prepare acrylic cutting files

Vinyl skin (Alternate to Silicone) supplies:

Vinyl sheets

Household hot iron

Baking paper

Tubing for Air Pumps and Valves – 3mm

Electronics supplies:

2 x Air Pump and Vacuum DC Motor – 4.5V and 1.8 LPM

MPU6050 accelerometer

Arduino Nano

Jumper wires

9v battery

9v battery clip

2 x Diode rectifier

2 x MOSFET IRF520N

Soldering kit

*not used but recommended: 6V Air Valve with 2-pin JST PH Connector

Step 1: The Coding and Wiring

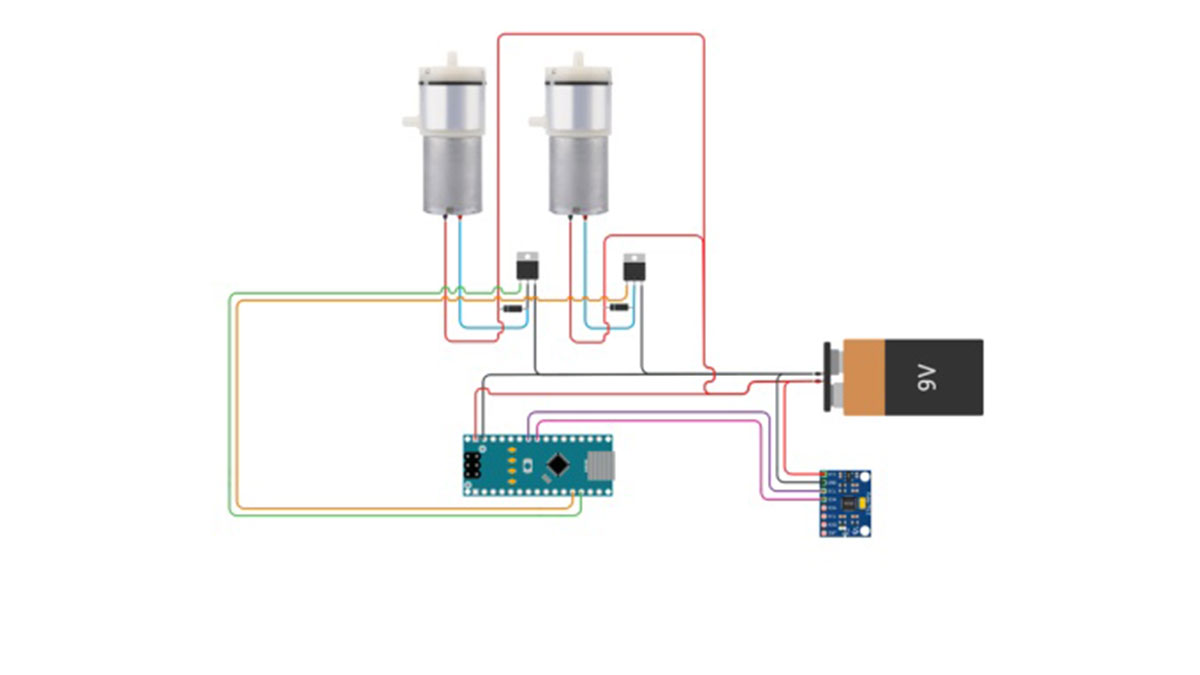

In this schematic diagram you will see the following diagrammatic components:

Air pumps

MOSFET’s

Diodes

9v and clip

Arduino nano

Accelerometer

The code below can be used within Arduino IDE:

#include

#include MPU6050 mpu6050(Wire); int DC_Motor_1 = 9; int DC_Motor_2 = 10;

// variables to hold the new and old positions float oldPosition; float newPosition;

// state holds the current status. // 0 = all off. // 1 = Dc_motor 1 // 2 = DC_motor 2 byte state = 0;

void setup() { Serial.begin(9600); Wire.begin(); mpu6050.begin(); mpu6050.calcGyroOffsets(true);

pinMode(DC_Motor_1, OUTPUT); digitalWrite(DC_Motor_1, LOW); pinMode(DC_Motor_2, OUTPUT); digitalWrite(DC_Motor_2, LOW);

}

void loop() { mpu6050.update(); newPosition = mpu6050.getGyroY(); delay(1); Serial.println(newPosition); // shake the sensor for quarter second to go to new Position. delay(250); // idle until new position become equeal to the old one.

digitalWrite(DC_Motor_1, LOW); digitalWrite(DC_Motor_2, LOW); // has the shake is over threshold. if ( newPosition >= 400 ) { digitalWrite(DC_Motor_1, HIGH); delay(4000); digitalWrite(DC_Motor_1, LOW); delay(500); digitalWrite(DC_Motor_2, HIGH); delay(2000); }

}

——————-

Note: within Arduino IDE>Tools>Board> “Select Arduino Nano”

Step 2: Acrylic Trays

Product:

1.5mm Acrylic layers Acrylic Glue Application syringe

Instructions:

– Prepare files in CAD software or equal with intent to cut acrylic on a laser cutter

– Cut acrylic pieces

– Use acrylic glue to make trays “molds” on which to pour silicone

Assemble acrylic 1 ply for all designed air bubble chambers

Assemble acrylic 2 ply for all designed pour boundaries and internalized holes

Step 3: Pour Silicone

Product:

Smooth On | Ecoflex 0030

Gloves

stir

Instructions:

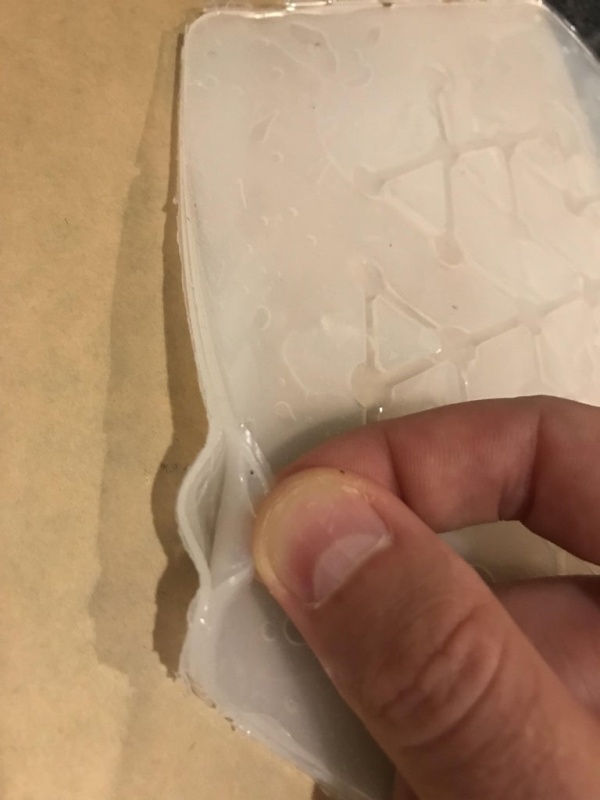

Pour Parts A and B 1:1 as instructed Make sure tray is level as the product is very runny 270 minute Cure time Extreme caution and precision when peeling silicone from acrylic trays

Step 4: Silicone Joining and Testing

Product:

Same Smooth On silicone as used in the pour

Air pump (to test)

Small brush

Gloves

Mixing cup

Stir

Instructions:

Once silicone molds have cured, remove silicone from acrylic and bond 2 sheets together to create airtight chambers within the material. A small brush was used to lightly spread apply silicone onto the surface of the cured silicone sheet (It is important to use the same silicone to assure bonding). Make sure to not apply silicone to areas intended for air chambers.

Once cured, the air pocket was tested by using a pump to check for leaks, additional silicone was lightly applied where needed to contain leaking.

The silicone tube that punctures the air chamber must be sealed with additional silicone.

Step 5: Mount Electronics | Final Product

Product:

Silicone tubing

Silicone “T” connectors

Instructions:

Mount electronics as required. Connect Micro vacuum pumps to the air chamber through silicone tubes and connectors as required.

Step 6: Vinyl Production

Product:

Vinyl sheets

Household hot iron

Baking paper

Instructions:

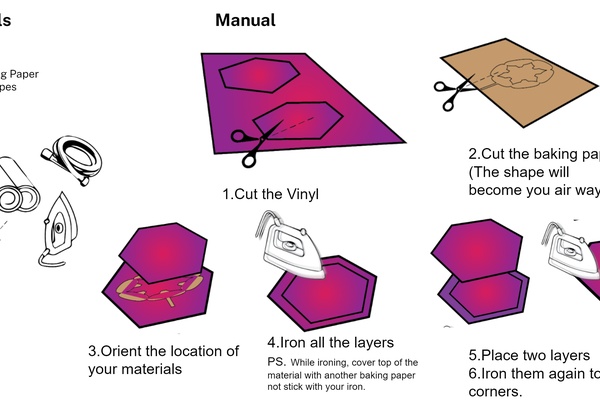

Cut vinyl to size

Cut baking paper shapes to create air chambers

Sandwich baking paper between two sheets of vinyl

Use iron to bond vinyl together (ps. use a sheet of baking paper between the iron and the vinyl)

Source: Bounce Back!