The United States of America currently holds 20% of the infected individuals with the COVID-19 virus. Considering the ongoing pandemic, an automatic hand sanitizer would result in a decrease of viral spread when placed in the center dash, whenever travel is necessary using a car.

This is a handy unit you can build to place in the cup holder in your center console. It is powered by a USB cord. It utilizes a standard 3 ounce spray bottle from Target and Isoprpyl alcohol. It’s easy to use and refill!

When you turn the car on, the unit will alert you with a series of beeps to remind you to use the hand sanitizer. Then simple place your hand by the sprayer and it will pump 3 short pumps delivering the right amount disinfect your hands. This way it you don’t have to touch anything before you sanitize your hands.

Supplies

1 Arduino UNO

1 MG996R servo

1 Ultrasonic sensor HC-SR04

1 buzzer

1 10 -OHM resistor

Arduino project wires

9 4-40 screws and nuts

3 6-32 screws and nuts

1 USB A to B cord. The standard USB cord that comes with the Arduino might be too short. Determine the length of cord you will need to go from the unit to a USB plug.

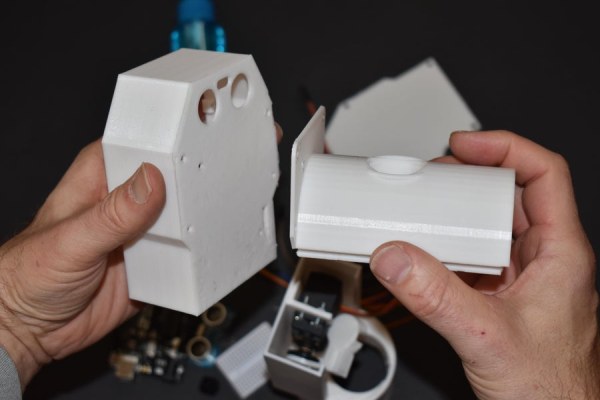

Step 1: 3D Print Your Parts

SLT files below.

Also, Solidworks 2019 file included below. You can alter if needed.

We used PLA to print the parts.

Determine the best orientation for quickest print in your software.

After printing the parts, use sandpaper or a Dremmel to clean up the edges.

If you wish, this is a good time to paint the parts, whether you used a colored PLA and want to add some character, or if you are using a base color PLA, you can liven it up with some vibrant colors.

This is a good time to lay everything you need for the project.

Remember a screw driver, you’ll need it!

Step 2: Place the Horn and Actuator on the Servo

- Push the round horn onto the servo

- line the middle hole of the actuator with the middle of the horn.

- use a 4-40 screw to the actuator to the servo shaft.

- Use the the second screw to secure the actuator to the servo horn

- Remember to align the actuator as in the last picture. The servo is upside down. You will need this for spacing.

Step 3: Install and Test Servo

- Place the servo in the main body and use screws and bolts to secure.It’s tight quarters!

- The top two are not so bad, but on the bottom I just did the outside one. It’s plenty strong

- You will need to hook the servo up the Arduino to make sure the starting angle is right. you want to have the actuator at the angle about 60 degree off horizontal with the servo upside down, like the last picture.

- Hook the servo up to the Arduino, red wire to 5V, brown/black to ground and yellow to pin 6. Run this code to set servo to 195 degrees.

- If you have to, remove the set screw on the actuator and rotate until it looks like the picture, then put set screw in. This will insure that when it’s all put together the servo is starting from the right spot.

#include

Servo servo;

void setup(void) {

servo.attach(6);

servo.write(195);

}

void loo() {}

Step 4: Put Front Panel and Top Deck Together

- Align The front panel and the top deck and secure with 4 screws and buts.

- If you push the screw from the bottom up and have the nut be on the inside, the project will look cleaners.

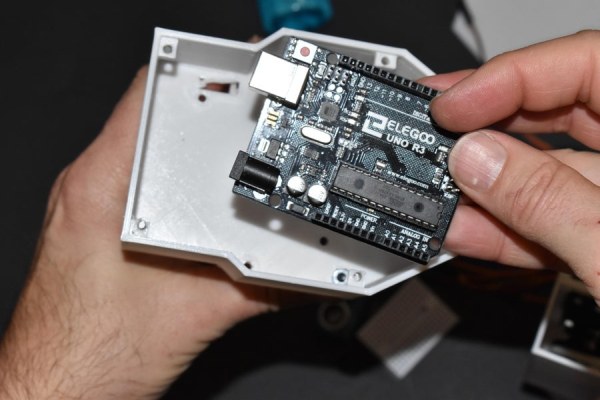

Step 5: Add the Arduino

- Place the Arduino into the top deck with the USB port in the square hole in the back and aligned with two holes in the bottom for screws.

- Use a screw and nut. At the end of the Arduino close to the front =, use the screw going from bottom to top for a better look.

Step 6: Join Front Panel and Main Body

- First thread the servo wire through the square hole on the floor of the top deck

- Slide the front panel onto the main body along the groove.

- Easy peasy!

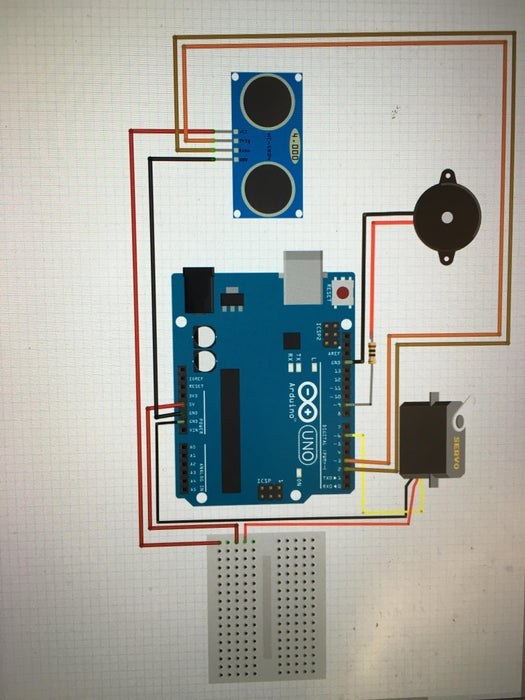

Step 7: Hooking Up the Guts

- First add the wires to the components as per wiring diagram

- and you will have a bird’s nest!

- It’s pretty tight in there, but there is enough room. Be careful to arrange the components and the wires such that they don’t interfere with each other because the end is near, only the top lid left!

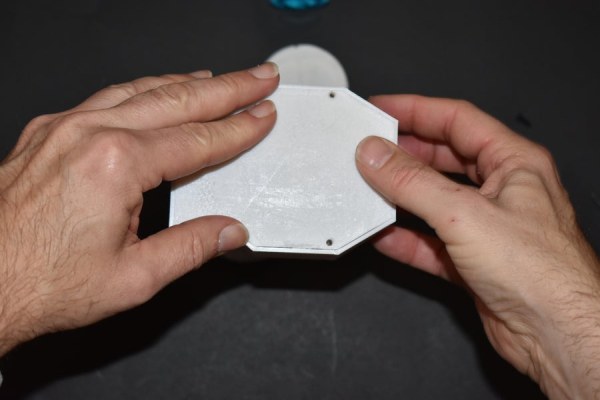

Step 8: Screw Top and Bottom Lid On

- Place the top lid on being careful with the wires and used 4 screws to secure

- Push the spray bottle up into the body

- ** Make sure the spray nozzle is facing to the hole in the front.

- Place bottom lid on and use 4 screws to secure.(This is how you will refill the bottle later)

YOU ARE DONE!

Step 9: Add the Code

Attach the Arduino to your computer and upload this code.

#include

Servo servo;

#define echoPin 2 // attach pin D2 Arduino to pin Echo of HC-SR04

#define trigPin 3 //attach pin D3 Arduino to pin Trig of HC-SR04

// defines variables

long duration; // variable for the duration of sound wave travel HC-SR04

int distance; // variable for the distance measurement HC-SR04

int distance2;

int loopcount;

const int buzzer = 9; //buzzer to arduino pin 9

void setup(void) {

// serial port for trouble shooting

Serial.begin(9600);

////Servo

servo.attach(6);

////US Sensor

pinMode(trigPin, OUTPUT); // Sets the trigPin as an OUTPUT

pinMode(echoPin, INPUT); // Sets the echoPin as an INPUT

pinMode(buzzer, OUTPUT); // Set buzzer – pin 9 as an output

for(int i=0; i<10; i++){ // This loop increases the tone of the buzzer

tone(buzzer, 1500+ i*50); // Send sound signal…

delay(100); // …for tenth of a sec

noTone(buzzer); // Stop sound…

delay(100); // …for tenth of a sec

}

}

// main loop

void loop() {

sensor_function();

Serial.println(distance);// Trouble shooting

delay(200);

if (distance == 6) { // this looks for the distance to actuate the sprayer

if (distance == distance2) { // because the ultrasonic sensor data moves quickly and sometimes sends flase signal

// so I want two readings of six before I trip the servo

Serial.println(“spraying”);// troubleshooting

///// three pumps

servo.write(195);

delay(200);

servo.write(145);

delay(200);

servo.write(195);

delay(200);

servo.write(145);

delay(200);

servo.write(195);

delay(200);

servo.write(145);

delay(200);

servo.write(170);

}

}

distance2 = distance;// this stores the current distance and will be comared to next reading for two in a row

}

void sensor_function() {

// Clears the trigPin condition

digitalWrite(trigPin, LOW);

delayMicroseconds(2);

// Sets the trigPin HIGH (ACTIVE) for 10 microseconds

digitalWrite(trigPin, HIGH);

delayMicroseconds(10);

digitalWrite(trigPin, LOW);

// Reads the echoPin, returns the sound wave travel time in microseconds

duration = pulseIn(echoPin, HIGH);

// Calculating the distance

distance = duration * 0.034 / 2; // Speed of sound wave divided by 2 (go and back)

// Displays the distance on the Serial Monitor

}// end of code.

Source: Automatic Hand Sanitzer for Your Car