Copper-based connectivity has served us well for a long time and will continue to do so in applications where it is effective from a performance and cost perspective. For very-high speed and/or long-distance signaling, however, the material cost and physical signal limitations of using metallic conductors has driven eyes to other transport mechanisms.

Fiber optics is not new, and the telecom industry has pushed development and deployment of fiber-optic transceivers and links so that they now span the globe. Very few of our designs have had the need to traverse long distances at such high speeds. Even fewer of us have had deep enough pockets to set up vast high-speed networks. On the other hand, engineers now are finding that local requirements are pushing the limits of metallic interconnects.

That is because the need for communications is not just long-distant cabling between computer centers. Communication necessities also extend to rack-to-rack and even board-to-board within a box, all of which is pushing fiber-optic technology into more high-speed designs.

Legacy COM links on MCUs were adequate for sub Mbit/sec data rates. Then Ethernet took us from 10 to 100 Mbit/s and now 1 Gbit/s links are commonplace. This is where copper runs out of steam and fiber starts to shine.

This article looks at issues and concerns engineers face when interfacing microcontrollers and fiber optics. This includes the rudimentary tasks of setting up and controlling laser emitter power levels and sensitivity thresholds for receivers, as well as tracking performance in real time. All parts, datasheets, tutorials, and development kits referenced in this article can be found on the Digi-Key website.

A view from the top

We can classify the microcontroller marriage to fiber optics into two main categories. On one side are high-end network processors. These implement and decode protocols from multiple data streams at very high speeds, usually in conjunction with an FPGA, and these parts are a class unto themselves.

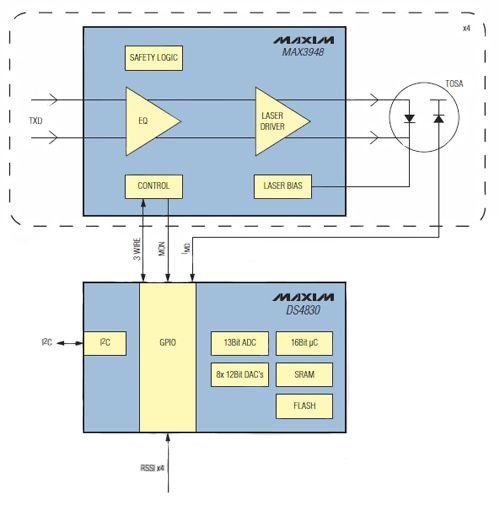

On the other end are the smaller, dedicated processors that either control or live within (or in close proximity to) modular or discrete transmitters, receivers, or transceivers. Discrete detectors, emitters, lasers, fiber connectors, and cable assemblies certainly let us place all fiber-optic elements on our own boards. The entire communications link can be replicated on a circuit board when only a few links are needed.

Our main embedded processors can certainly store and retrieve calibration data for transmit power levels, receive bias, and thermal compensation. These can be set up sequentially during power-up and reset as part of the initialization process. Tracking performance and dynamically adjusting communications parameters for many links in real-time, however, can take its toll on a central host processor, especially if many fiber-optic links are needed.

For more detail: Microcontrollers and Fiber Optics