Organic light-emitting diodes – OLEDs – emit light when a current flows through them. Unlike conventional LEDs, OLEDs are made from layers of plastic and other organic (carbon-based) materials.

Examples are already in mass production for displays in MP3 players and phones.

Sheets of OLED material are proposed to replace light bulbs and fluorescent tubes for house and office lighting.

There are several reasons why OLEDs are causing so much excitement amongst makers of gadgets and lighting products:

- The materials are deposited by industrial coating processes which are cheaper than the techniques required to make conventional LEDs.

- They are inherently thin.

- They can be made on flexible plastic substrates – which will almost certainly lead to full colour flexible displays less than 1mm thick.

- All colours, and multi-colours, are possible

However, there are drawbacks:

- OLEDs are not yet as efficient at making light as conventional LEDs, although they are getting closer and already beat ordinary light bulbs.

- Certain materials in OLEDs are incredibly sensitive to moisture which leads to short life, particularly on plastic substrates. This is the main reasons holding back flexible OLED manufacture.

- LED technology can be divided into two: ‘small molecule’ championed originally by Kodak, and Cambridge Display Technology’s ‘polymer’ type sometimes called P-OLEDs.

Almost all displays in production are small molecule.

These materials have to be deposited in a vacuum, but this is of little inconvenience for small displays on glass substrates.

Polymer types can also be vacuum processed but, most importantly, can also be printed using standard printing techniques. This ‘solution processing’ is far cheaper than vacuum processing.

Like-for-like materials have tended to be less efficient at producing light when solution processed, but this may no longer be the case.

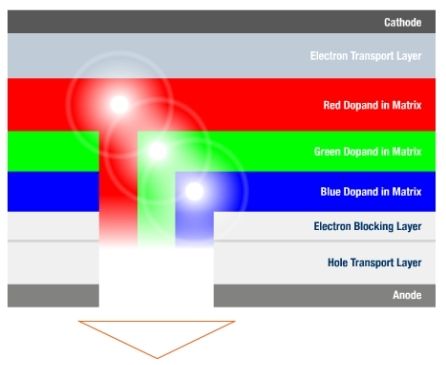

OLEDs are generally made of several layers. The following is a typical stack, although many variations are possible:

- Anode

- Electron donor

- Electron transport

- Emitter

- Hole transport

- Hole donor.

- Cathode

Several of these can be moisture-sensitive, particularly the most effective cathode material: metallic calcium.

For all practical purposes, glass blocks all moisture, so displays made on a glass substrate and covered by a second glass sheet can have a long life, particularly if the edges are hermetically sealed.

Moisture passes fairly easily through plastics, leading to much reduced durability, but plastic substrates are essential for flexible displays.

This has lead to a quest for ‘barrier layers’ which can be coated on plastic to stop moisture getting through.

So far there is no effective barrier layer that is flexible and cheap enough for mass-production.

For more detail: Flexible and transparent OLEDs at LG