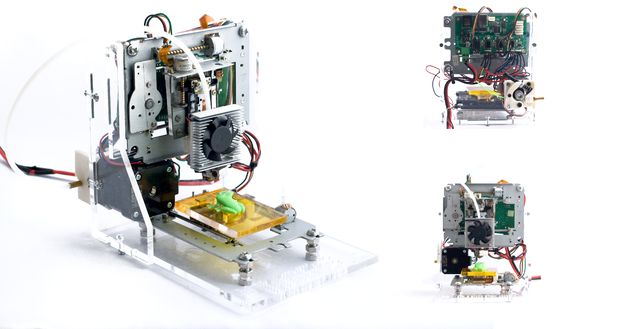

This project describes the design of a very low budget 3D Printer that is mainly built out of recycled electronic components. The result is a small format printer for less than 100$.

First of all, we learn how a generic CNC system works (by assembling and calibrating bearings, guides and threads) and then teach the machine to respond to g-code instructions. After that, we add a small plastic extruder and give an overview on plastic extrusion calibration, driver power tuning and other few operations that will bring the printer to live. Following this instructions you will get a small footprint 3D Printer that is built with about an 80% of recycled components, which gives it a great potential and helps to reduce the cost significantly.

On one side you get an introduction to machine building and digital fabrication and on the other side you get a small 3D Printer built out of reused electronic parts. This should help us to be more conscious about the big problems related with e-waste generation.

Step 1: Step 1: X, Y and Z axes

Needed components:

2 standard CD/DVD drives from an old PC.

1 Floppy disc drive.

We can get this components at no cost in a waste station in our neibourhood. We want to make sure that the motors we get from the Floppy disc drives are stepper motors and not DC motors.

For more detail: EWaste 60$ 3DPrinter Using Arduino