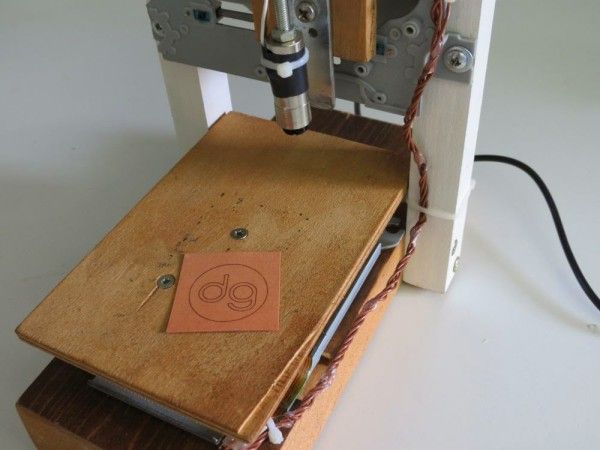

To build this tool I’ve used two old CD-ROM writer that lays around in my garage.

The X/Y positioning system it is build using the CD-ROM motor assembly. For the engraving laser i use the CD-ROM writer laser.

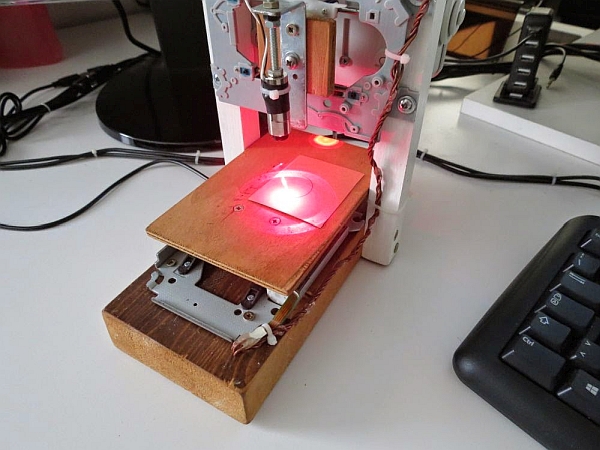

In CD-ROM and DVD-ROM you could also find IR driver, DVD laser writer diode will be a little more powerfull than the CD one.

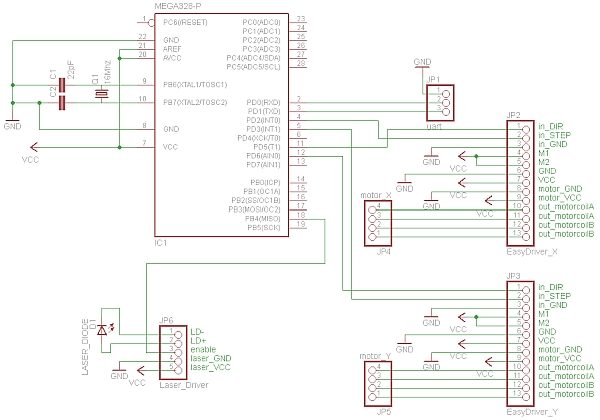

Laser diode usually has three pins, one is the common ground, laser and photodiode cathode (-), one the laser diode anode (+), the other is the monitor photodiode anode(+).

If the diode you are using has no mark, and you do not know the diode pinout, you have to find the laser cathode and anode. One simple method I use is to power up the diode with a 1.8 to 2.2v current, just for a little amount of time, let’s say 1s, if it sucks current, that wiring is the laser diode pinout.

Once again, if you do not know the motors wiring, you have just have to pay attention to pair each coil and then connect to the EasyDriver motor output. If direction is inverted, invert the coil wiring, or just setup grbl to invert the axis direction.

I’m using grbl version grbl v0.8c (ATmega328p, 16mhz, 9600).

You just have to upload the firmware using your favorite uploader, the grbl wiki page drive you on how to do this step.

On the grbl wiki page you could also find any other information about command and software setup.

Commands to the engraving machine are sent through UART.

When you assembly your harware, pay attention to build it making X normal to the Y axis. The two direction has to be perpendicular, or your engraving will has distorsion.

Below you should find the schematics i’m using.

Below you can find the grbl configuration parameters i changed, basically what i’ve changed here is:

Set step/mm to setup the correct motor distance to run (a common step/mm value for CD-ROM motor should 53.333):

$0=53.333 (x, step/mm)

$1=53.333 (y, step/mm)

Set the accelleration value to 100:

$8=100.000 (acceleration, mm/sec^2)

Enabled the homing cycle:

$17=1 (homing cycle, bool)

If you need to invert axis direction, “Step port invert mask, int:binary” is the paramenter you have to touch. Those are the most common inversion, but if you need other inversion, look at the grlb wiki for this parameter:

$6=32 (invert x axis)

$6=64 (invert y axis)

$6=96 (invert x and y axis)

To test it, just send the

X10 Y10

command, or use the Grbl Controller rows, you should see a 10mm movement on each axis.

Also check the “spindle on” command power your laser on and off.

Now you could be able to send g-code drawing to your engraver.

The working are for this plotter is 38mm x 38mm, so setup your project area to this dimension.

Once you have you path, then you could select the path you want to engrave, and transform it using the InkScape laser engraver extension.

Just copy the extension on your extension inkscape folder, restart inkscape, and use that to build your g-code file.

Once you have your g-code file, you could send it to grbl using Grbl Controller, or other software like Universal-G-Code-Sender.

Notes

- read risk disclaimer

- excuse my bad english