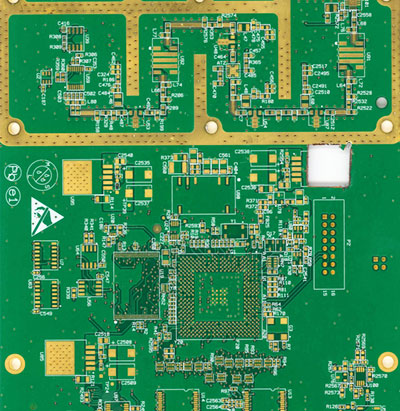

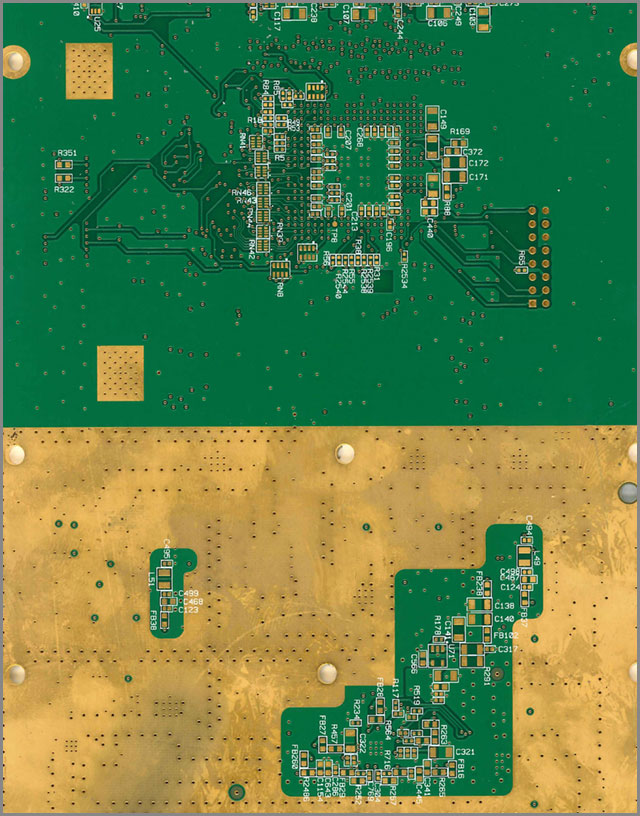

OurPCB Published a Guide on ‘HASL VS ENIG-How to Choose the Right Surface Treatment Method’

OurPCB, a reliable PCB & PCBA service manufacturer and provider, today published a “HASL VS ENIG-How to Choose the Right Surface Treatment Method.”

SHIJIAZHUANG, China, July 17, 2019 (Newswire.com) –OurPCB, a multi-national PCB Manufacturing and PCB Assembly company, today published a Guide on “HASL VS ENIG-How to Choose the Right Surface Treatment Method.”

Through the following four chapters, we will guide you to choose the right type of surface treatment to suit your project type, and point out your perfect supplier, relieve your stress and ease your worries.

The publication is available on the https://www.ourpcb.com/hasl-vs-enig.html section of the company’s website for free. It is a simple guide authored by the OurPCB technical team to help both beginners and professionals have a Better understanding of The difference between HASL VS ENIG.

Among the key subjects on The difference between HASL VS ENIG include:

1.HASL: This section provides a brief overview of the definition, function, and benefits of hot air solder balance.

2.ENIG: This section introduces ENIG mainly through three aspects: Definition, ENIG finish, ENIG plating.

3.HASL VS ENIG: This section focuses on the advantages and disadvantages of HASL and ENIG.

3.1 The benefits of HASL are:

- easy to use

- low cost

- Long storage life

- Good surface finish

- Ensure that copper does not oxidise

- Continuous to maintain wetting

- Visual inspection of surface finish

3.2 The disadvantages of HASL are:

- Not applicable to surface mount technology surface

- Not suitable for fine pitch

- Not ideal for manufacturing

- Due to high heat exposure in the process, there may be some disadvantages

- Unable to withstand the tight tolerances of plated holes

- Hot air solder flat is not suitable for wire bonding

- When using this surface treatment, the plated through holes may be broken due to high temperature

3.3 ENIG advantages:

- Ideal for surface treatment of plated through holes, good storage life, It has no lead,

- Ideal for use as bottom metal for cob wiring, excellent electrical conductivity,

- Has the ability to prevent oxidation

3.4 ENIG’s shortcomings: expensive, non-reusable,

- Electroless nickel immersion gold is associated with signal loss, NIG’s process is complex,

- And black liners are prone to occur due to its low volatilisation strength.

4. Other surface treatment processes:

This section is from the following five aspects:

Organic Solderability Protection (OSP), Hard Electrolytic Gold, Dip Tin, Impregnated Silver, Nickel Palladium (ENEPIG), their advantages and disadvantages provide in-depth information on other surface treatment processes.

If you have any needs or questions, feel free to contact us. There is a lot of knowledge about PCB on the website to help you know more about what you want when purchasing PCB and PCBA services.

About OurPCB

OurPCB is a multi-national PCB Manufacturing and PCB Assembly company that provides Global service and support while utilising its Chinese manufacturing capabilities.

Our Assembly factory has received ISO9001 certification. for bare PCB manufacturing, we also received ISO and UL certifications.

Media Contact:

Contact Person: Hommer Zhao (General Manager)

Email: [email protected]

Tel: +86-311-85981900

Website: https://www.ourpcb.com

Source: OurPCB Tech. Ltd.