Introduction!

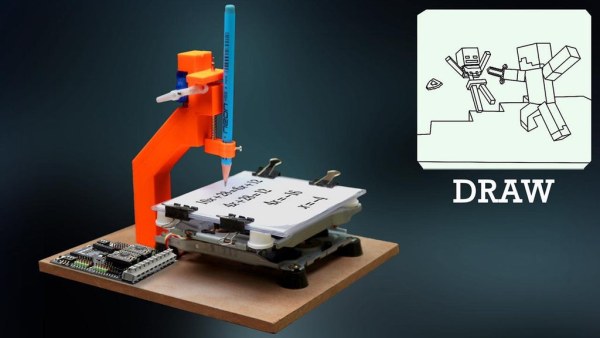

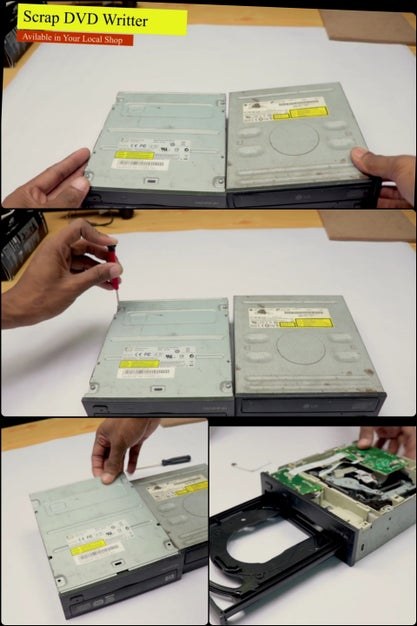

Hi Friends Welcome to the DiY Projects Lab insctructable , I hope you all are well, so today we are going to learn how to make your own 3D Printed CNC machine. It is a prototype module, but once you build it you will definitely be able to build a very large CNC machine and with much higher accuracy. The principle will be the same, we will use DVD Writers Stepper Motors to control the movement of 3 axis of CNC machine.

VIsit DiY Projects Lab For More CNC Like this

Supplies

Let’s Make It

List of some use full material required

Arduino nano x1

CNC shield x1 A4988 Stepper motor Driver x2

Servo motor x1

pen x1

old DVD Scrap X2 Some wires

Step 1: What Is CNC ?

CNC (computer numerical control) The system is based on the control of the movements of the work tool in relation to the coordinate axis of the machine, using a computer program benbox executed by a computer.it is necessary to control the movements of the tool in two coordinate axis: the X axis for the longitudinal movements of the carriage and the Z axis for the transverse movements of the tower. servo motors are incorporated in the carriage and turret displacement mechanisms.

AXIS MOVEMENTS

X axis – left to right

Y axis – front to back

Z axis – up and down

3 Axis

Automatic/interactive operation

Milling slots

Drilling holes

Cutting sharp edges

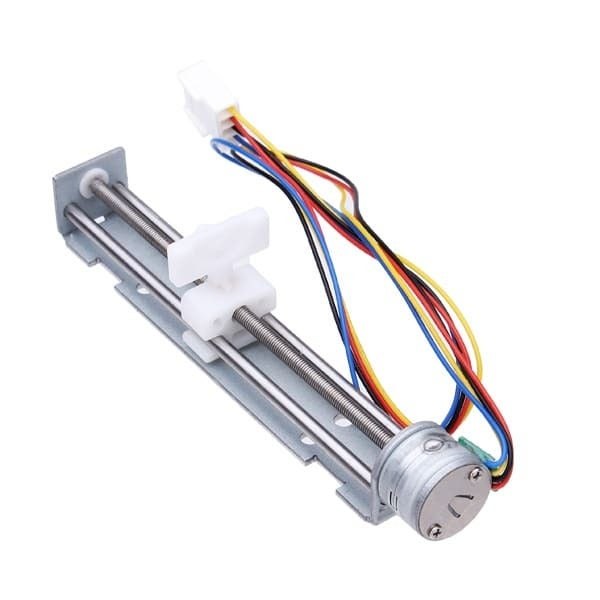

Step 2: What Is Stepper Motor ?

The stepper motor is an electromechanical device that converts a series of electrical impulses into discrete angular displacements, which means that it is capable of advancing a series of step depending on its control inputs. The stepper motor behaves in the same way as a digital-to-analog (D / A) converter and can be driven by pulses from logic systems. Its main applications include a variable frequency motor, brushless DC motor, servo motors and digitally controlled motors

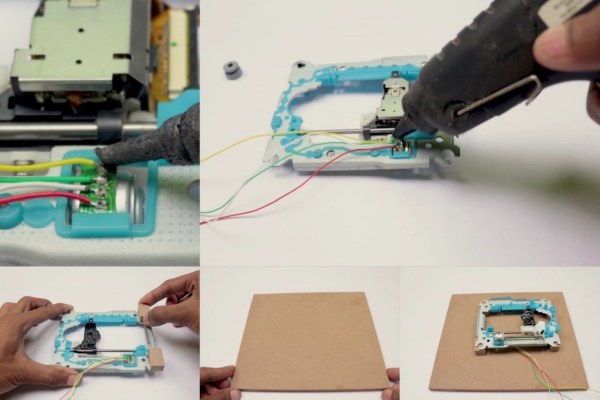

Step 3: DVD Drive Stepper Motor Disassembly

First of all we must open the 2 DVD scrap to extract the motors and moving parts necessary for the CNC machine. We must open them carefully so as not to the break the pieces we need. In the following image we can see Image. Simply by unscrewing the 4 screws marked in the image we can extract the part which we need, a whole shaft together with a stepper motor.

Step 4: Attach Motor With Base

We have soldered the wire with stepper motor and then given it a spacer with a piece of wood. (As shown in the picture below) we cut a wooden plate that will be our base.

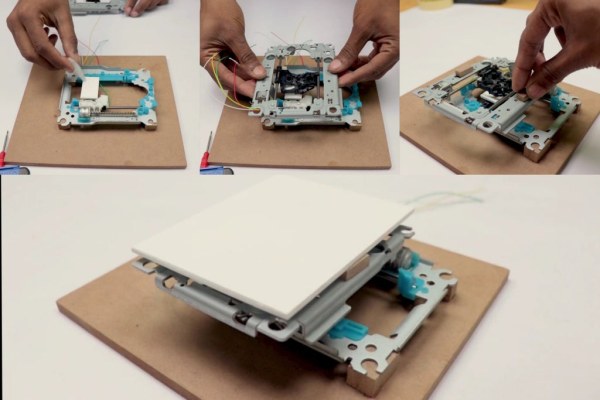

Step 5: X-axis and Y-axis Co-ordinates Movement.

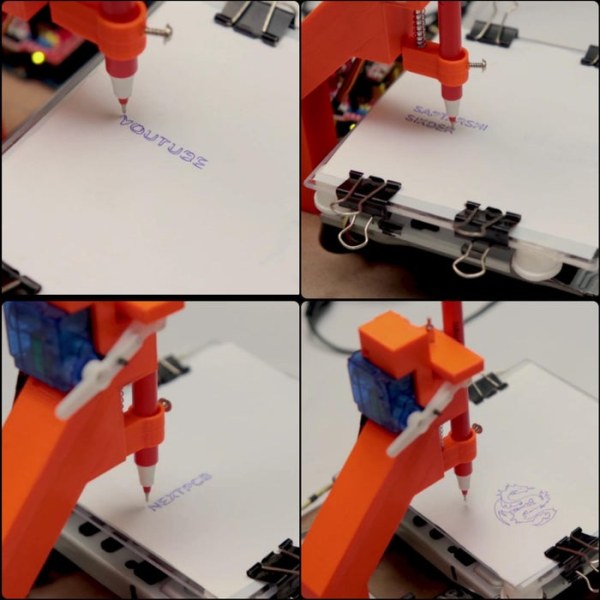

I’ve attached the slider of X and Y-axis together in perpendicular to each other, using glue between them. And also attached a cut wood piece above it as a working bed.

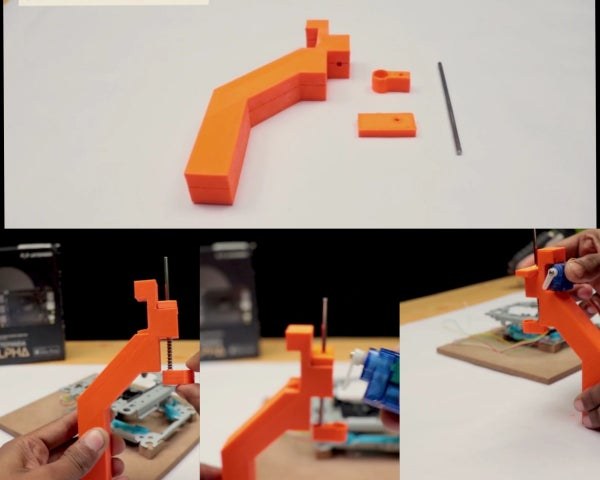

Step 6: Assemble the Pen Holder

Attach the pen holder with bed

i have use 3d printed Pen holder

you can also print this holder

Step 7: The Electronics

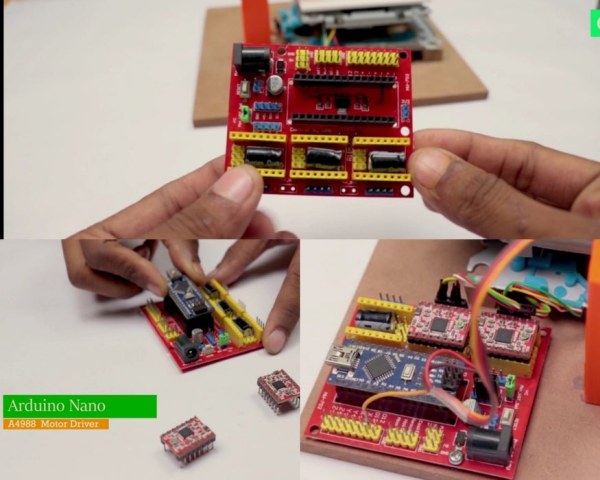

CNC Shield v4

This is the Shield CNC v4 for Arduino Nano, it is a 3 axis stepper motor controller, ideal for creating your own three axis CNC or laser engraving machine. This card can control two phase (4 wire) stepper motors up to 2A. It has a digital I / O interface, easy to connect to other modules, such as ENDSTOP, it also has an I2C interface, it can be connected to the I2C LCD or another I2C module. The power supply is 7.5-12Vdc, and the control logic is 5Vdc. This card is GRBL compatible.

Ready to your all circuit

1) 2 PCs A4988 Stepper Motor Driver 2) v4 Expansion Board A4988 Driver 3)Arduino Nano First of all take hit sink and stick on A4988 motor Driver. 2 pcs A4988 Stepper motor driver connect on expansion board A4988 driver module. then connect the arduino nano with expansion board and connect all wiring

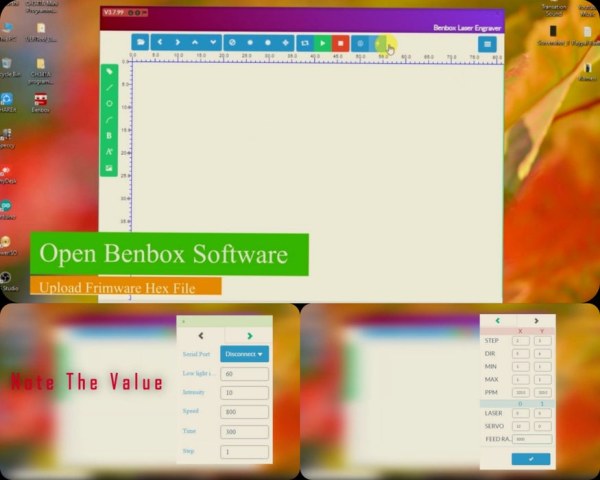

Step 8: Benbox Softwer Configuration

Software

visit DiyProjectsLab For more info

Source: 3D Printed Mini CNC Machine