This project is a collaboration between idesigner4 and bhasudha(me), students in the Fall

2012 course Things That Think (CSCI 7000) at The University of Colorado – Boulder.

The story of our bug-catching spider automaton goes like this: A giant evil spider resides

in a big web. One day an unfortunate lady bug gets trapped in the web and the scary

spider pounces on it.

We came up with the idea for this six-week project together and discussed implementation

possibilities at length, particularly with respect to moving the spider and detecting the bug.

For example, although we ended up using IR sensing for bug detection, we considered

several other possibilities including touch sensors and image processing. At that point, the

highly modular and reusable nature of the project components allowed us to build

separately, and we are posting our Instructable as a two-part series.

Part 1, described in this Instructable, shows how to build the following elements:

* The frame to which everything is attached

* The spider web and associated lighting

* The spider mover, which is an XY table beneath the web

Part 2 shows how to build the remaining elements:

* The bug detector

* The bug

* The spider

Readers who would like to build this project should be aware of the following limitations:

The XY table moves nicely under human power, but not with the servos, and we think this

outcome is a result of the materials not being sufficiently rigid. It’s possible that adding

another servo to move the lower slider from both sides would be helpful, too. Here are

some alternative Instructables XY tables to try:

Low Cost Hobby Servo XY Table

Internet Arduino-Controlled T-Slot XY Table

DIY CNC Router

Our intent was to be able to display the web in any position, such as leaning against a wall.

For this reason, we used strong magnets on both the spider and the mover. Although this

idea worked well with models during pretesting, the final spider clings too tightly to the

web and doesn’t move well. For this reason, we would recommend a different spider /

mover magnetic connection, as well as stronger servos to help overcome drag.

The spider’s orientation is fixed. We had discussed using a rotating arm on the spider

mover, with the pivot point toward the front of the spider, but did not build it due to time

limitations. This arm would have allowed the spider to turn as it moved forward along an

arc traced out by the spider mover.

Step 1: Bug sensing mechanism

Here is a short video demonstrating how the bug sensing works. The overall mechanism is as follows:

The Arduino controller code interfaces with the IR grid and the motor. The IR grid identifies the position of the bug (the x,y coordinate) (as shown in the top right corner of the video). This X,Y coordinate is then passed to the controller which then decides how much to move the motor along X and Y to reach the bug. The controller code remembers its current position in the grid (current position of the spider) while calculating steps to move in X and Y. The motor and the IR grid are synchronized for timing, by the controller code.

Step 2: Materials Needed

nfrared grid – 10 x 10:

2 x Acrylic base (38 cm x 7 cm 3mm thick )

2 x Small Basswood (40 cm x 2.5 cm 1/8 inch thick)

2 x Big Basswood (38 cm x 8 cm 1/4inch thick)

4 x Solderless Breadboards (830 Tie Points. Board Size: 2.14″ x 6.5″. Around $7.99 each)

Variable length and colored Jumper wires (22 GA Solid Tinned Copper wire kit contains 4 colors. Around $13.51)

20 x 10K ohm Resistors(Available in packs of 5 or more)

1 x Mini Breadboard ( 170 tie points. Board Size 1.4″ x 1.6″. Around $3.99 )

20 x IR detectors(Also Known as Infrared Photo transistors Around $0.50 each for 10 plus units ordered)

1 x Arduino Mega (ATmega1280)

6 x wire connectors ( optional component. easy to identify the output wires)

6 x small metal clips to hold acrylic to the frame

Bug:

1 x Printed circuit Board (417 holes. Around $2.49)

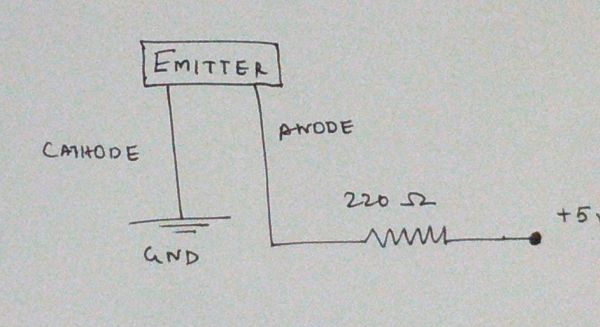

8 x IR Emitter ( pack of 25 costs around $7.95)

Red and Black variable length Jumper wires

Foam sheets(1/4 inch thick)

8 x 220 ohm Resistor (Available in pack of 5. Around $1.19)

Fabric paints ( colors of personal choice)

1 x Spring (Flexibility of the spring depends on the size of the bug)

Spider:

2 x Ball Magnets (1/4 inch diameter. Available in local hardware shop)

1 x rod magnet (any rod shaped . Example: magnetic construction kits)

Basswood ( 1/8 inch thickness)

Foam (1/4 inch thick. Used as a support inside the spider body)

4 x small disc magnets magnets (1/4 inch X 1/16inch neodymium disc magnets)

Thick metal wire (~18 Gauge. Strong enough to support spider legs)

Springs (choice of spring depends on the weight of the spider legs)

Black Pipe cleaners (pack of 25 around $1.19)

Decorative fabric ( Any decorative fabric that appeals to individual aesthetic preference)

2 x blue beads for eyes ( Any color that feels good to our imagination)

Machines & Tools:

Laser cutter

Devcon weld it – All purpose glue

Wire snipper

Cellophane Tapes

Soldering kit

Snap knife to cut foam

Drill

[box color=”#985D00″ bg=”#FFF8CB” font=”verdana” fontsize=”14 ” radius=”20 ” border=”#985D12″ float=”right” head=”Major Components in Project” headbg=”#FFEB70″ headcolor=”#985D00″]20 x IR detectors

1 x Arduino Mega (ATmega1280)

6 x small metal clips[/box]

For more detail: Bug-Catching Spider in Web, Part 2