Motor control is becoming the power industry’s fastest changing technology area. The reason for this is the requirement to improve energy efficiency from the millions of motors which are used in our homes, factories and cars.

New developments in motor controller design, current sensing and control algorithms will be needed if new and more stringent efficiency targets are to be achieved.

The main design elements of motor control can be broken down into four parameters – communications interface, EMC robustness, circuit isolation and energy efficiency.

It is in the area of energy efficiency where the biggest changes are likely to take place in the next few years.

According to Anders Fredriksen from Analog Devices, there is a big push to put more importance on energy efficiency in motor design, and this will increase over the next few years as new efficiency standards are introduced.

“Standardisation has been going on for decades but by 2017 extensions to energy efficiency guidelines being applied to motors down to 1W will have the biggest impact for manufacturers,” said Fredriksen.

But Frederiksen believes further advances in motor control design are still needed to meet the requirements of the new energy efficiency standards.

“There may be a need to change motor control architectures, we won’t achieve all the new efficiency standards without this,” said Fredriksen.

This will apply to the industrial motors as well as those in household appliances and cars.

This drive to increase energy efficiency needs to be applied at the component level. This means adding processor power to motor controllers to run the optimisation algorithms. It also requires increased accuracy when current sensing.

“For example, the use of isolated sigma-delta conversion for higher accuracy,” said Fredriksen.

ADI offers a high accuracy isolated sigma-delta converter for dc and ac current and voltage measurement.

The AD7403 achieves 81dBmin signal-to-noise and distortion ratio (SINAD, at 78ksample/s over -40 to 125°C). Higher SINAD enables more accurate current and voltage measurement which improves the performance of motor drives by reducing torque ripple on the motor shaft.

It has a second-order, sigma-delta modulator that converts an analogue input signal into a single-bit data stream with on-chip digital isolation (1,250Vpeak) through on-chip transformers.

Operation is from 5V at the measurement end and it accepts a differential input signal of ±250mV (±320mV full-scale). The analogue input is continuously sampled and converted to a ones-density bit stream with a data rate of up to 20MHz. The original information can be reconstructed with appropriate digital filtering to achieve 88dB signal to noise at 78.1ksample/s.

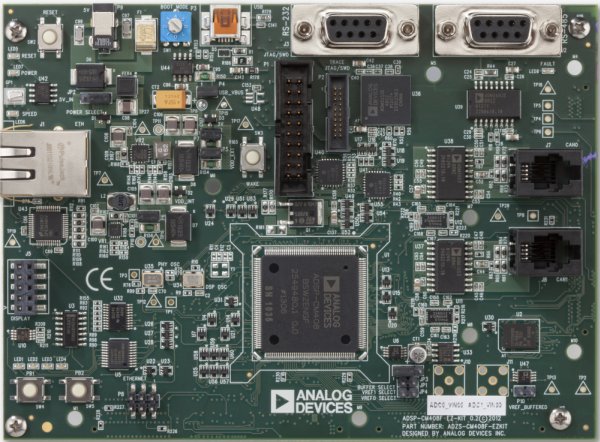

For data processing, microcontrollers are moving to higher performance cores such as the ARM Cortex-M4, which has DSP extensions.

“There has been a lot of work going on around algorithm development for motor control, the increase in processing capability which cores like the Cortex-M4 provide has brought these advanced algorithms into play,” said Fredriksen.

For more detail: New energy efficiency rules will change motor control design