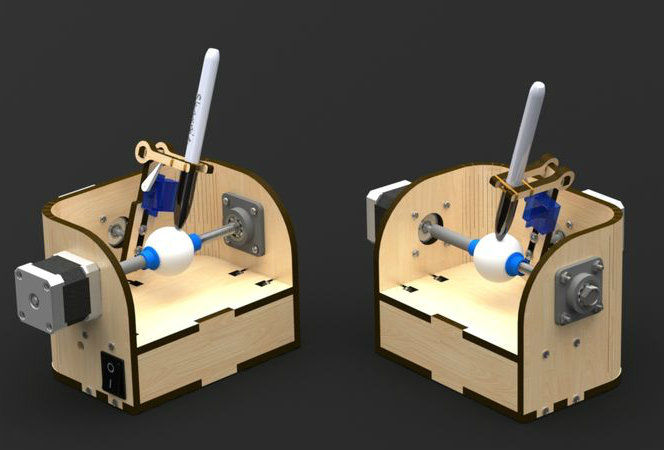

The Sphere-O-Bot is a simple 2 axis CNC machine that can draw on most spherical surfaces. You can use it to decorate ping pong balls or eggs.This design is based on the 3D printable Sphere-O-Bot. By building your Sphere-O-Bot using a laser cutter, you can achieve a clean look while also reducing the production time of your parts. This design also features an electronics bay for your wires, micro-controller, and motor drivers.

The Sphere-O-Bot described in this tutorial was designed for a workshop in which kids get to build their own motor controllers. For more projects by the Maker Corps interns at the Children’s Museum of Houston, visit our site: kidmakers.org

If you like this project, please consider voting for me in the epilog challenge. My internship at the Children’s Museum of Houston will end in a couple of weeks and so will my unlimited laser cutter access. Having a laser cutter of my own will allow me to keep developing more instructables for you. Thanks.

Step 1: Materials

You will need:

- 1/4” plywood

- Access to a laser cutter and 3D printer

- 9 6-32 screws/nuts

- 8 M3 screws

- Micro sized servo motor

- 2 NEMA 17 stepper motors

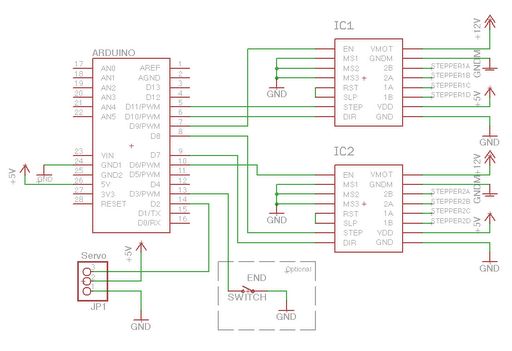

- Arduino Uno or comparable board

- Polulu A4988 stepper motor drivers

- Marker (Sharpies work well)

- 8mm threaded rod

- Wire

- Soldering iron

- Small spherical objects (ping pong balls, eggs, etc…)

- A metal spring

Optional:

Step 2: Laser Cut & 3D Print

Download the design file here and cut it out of the 1/4” wood using a laser cutter.You could probably also cut these out of plexiglass except for the curved part, since it would not be flexible enough.

The 3D printable files can also be found under the same Thingiverse post. The printable files are actually borrowed from this 3D printable Sphere-O-Bot design.

Disclaimer: It’s ok if the renders/pictures in this Instructable don’t exactly match the design file on thingiverse. That just means that I’ve been doing some design changes to help things fit better.

Step 3: Assemble the Frame

Using the 6-32 screws/nuts, join the curved part to the bottom piece. I found that if you insert the screws into the large piece and loosely attach the nuts, you can then bend it around the bottom piece and secure it with ease. Keep in mind that since the wood was originally flat so it will try to fight back against bending.

Now all you need to do to finish the frame is to secure the top and front panels of the electronics bay. BUT WAIT!!! You haven’t installed the electronics yet. Your life will be easier if you don’t attach the last two pieces of the frame until after taking care of the electronics.

Step 4: Marker Gantry

UPDATE: After realizing that the original design suffered from severe jitter, I re-designed the marker gantry to make it more sturdy. Check out this short animation to see how it works and how it is assembled. The micro sized servo is attached using M2 screws and the rest of the screws are M3. The hinge that I used can be found here, but feel free to replace it with any other hinge of a similar size. If you can’t find a hinge, you could probably just glue a flexible piece of plastic between the two main wooden pieces of the marker holder. The file for the new holder design is titled holderV2 in the Thingiverse post.

For more detail: Laser Cut Sphere-O-Bot using Arduino