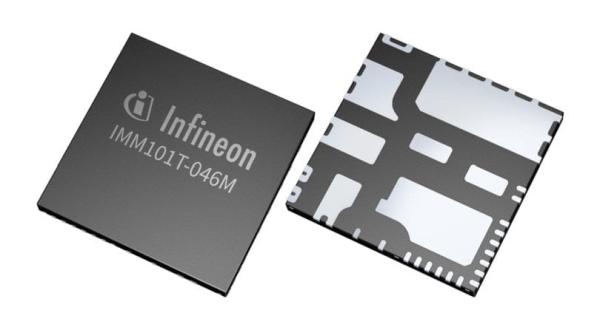

Infineon Technologies AG introduces smart IPM motor controllers featuring full hardware and software integration needed for BLDC motor drives of up to 80W without heatsink. The new iMOTION™ IMM100 series combines the motor controller IC and a 3-phase inverter stage in a single, highly compact 12 x 12 mm 2 PQFN package. This combination enables BOM count and PCB size reduction, thus lowering system cost. The smallest footprint of the motor drive IC makes it a perfect fit for space restrained home appliances like hair dryers, kitchen hoods, ceiling and air conditioner fans as well as pumps for dishwasher and washing machines. Additional applications include low-power fridge compressors, heating pumps and industrial pumps.

The IMM100 series offers two optimized variants to best serve the needs of design engineers. The T-variant features the highly sophisticated FOC algorithm integrated in the iMOTION MCE 2.0 (Motion Control Engine 2.0). This variant takes advantage of the easy-to-use software tools for system configuration and tuning. It can also be complemented with additional system level functionalities by using iMOTION scripting and, optionally, with PFC control.

Alternatively, with the IMM100 A-variant, engineers can implement proprietary motor control software by utilizing the fully programmable integrated ARM ® Cortex ®-M0 MCU – and still enjoy the benefits of complete hardware integration. In this case, the industry-standard ARM ® MCU IDE tools support the software design process, compiling and debugging. Both variants reduce R&D cycle time for the hardware design due to the high level of integration. Moreover, the T-variant significantly reduces the R&D cost and speeds up time-to-market thanks to production-ready MCE 2.0 software integration.

Read more: IMOTION™ IMM100 SERIES FROM INFINEON REDUCES PCB SIZE AND R&D EFFORTS SIGNIFICANTLY