In Part 2 of the DNA Melting Lab you will make revisions to allow greater control of your instrument and to reduce the effects of noise. You will add a pulse-width modulation (PWM) heater controller to enable careful control of the heating and cooling rates of the DNA sample. This will allow you to maintain a melting rate below the melting rate of the DNA and to work around the thermal lag of the instrument.

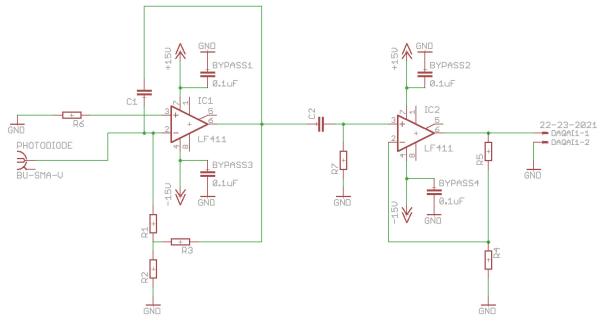

You will use an op-amp to enable modulation of the light flux emitted from the blue LED. The modulated illumination will then result in an oscillating amount of fluorescent light flux from the DNA sample. The oscillating flux signal will be detected by a photodiode and then amplified and demodulated using a lock-in amplifier. The modulation will allow you to place your signal in a low-noise area of the frequency spectrum, and the lock-in will allow you to recover the signal. Review your lecture notes, find an instructor, and review the Understanding the lock-in amplifier wiki page.

Add a heater/cooler/controller board to thermal subsystem

In your instrument, both the actual and apparent behavior of the melting DNA sample are dependent on the heating and cooling rate of the sample holder. The temperature of the DNA sample always lags behind that of the sample holder. If the rates are reasonable, then the lag is not severe and a correction can be applied to the measured sample holder temperature to predict the sample temperature. If, on the other hand, the rates are too

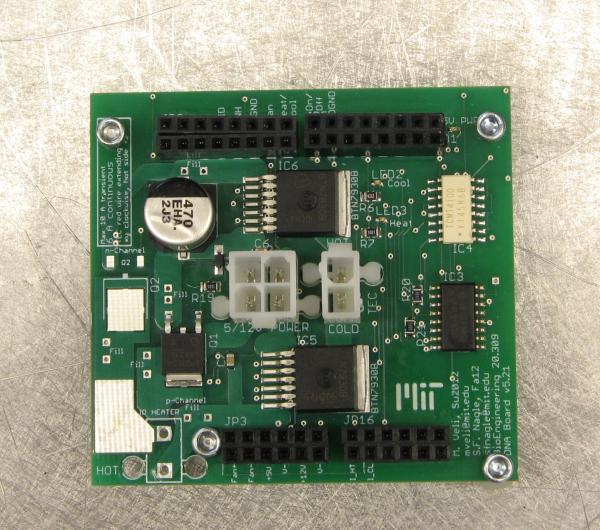

high, then the correction becomes unreliable. In addition, the melting and annealing reactions have a time scale associated with them as well. You will control the rates to yield the best data possible with your instrument. To do this, a specially-designed printed circuit boards (PCB) is provided. The PCB controls the current supplied to the TECs in contact with the smaple holder. Since the sample holder is aluminum, the parts of it in contact with

the TEC, the RTD and the sample vial are all identical for reasonable heating and cooling rates. The PCB will be controlled by a modified version of the software, which you will implement later on in Part 2.

Parts

Gather the following components:

- 1 PCB heater-cooler board from the Center Cabinets or the East Cabinets.

- 1 red/black connector cable from the East Cabinets.

Assembly

Points of connection are labeled on the PCB and described in the table and figure below. Refer to both in the instructions that follow.

- Disconnect the yellow/white cable between the supply and the TEC stack.

- Place the PCB in the pre-drilled holes on the sheet metal support bracket.

- If the nylon “feet” are missing, add them now. They are in the DNA Melting drawer at the right of the Wet Bench.

- Turn off the Diablotek power supply.

- Connect the Diablotek and check power

- Connect the Diablotek 4-pin/3-color power supply connector to the 4-pin connector on the PCB.

- Quickly cycle the Diablotek power to confirm a green power status light in the upper right corner of the PCB.

- Confirm that the Diablotek is off.

For more detail: DNA Melting Part 2: Lock-in Amplifier and Temperature Control