Opening 26 pieces of windows at the same time in a 2,000-square-meter greenhouse under just 20 seconds? Yes!

Story

2 years ago I decided to step to a new level in controlling micro-climate in our thermal water heated greenhouses. Before that time for example we did all airing by opening-closing windows manually. It was a waste of time, took hours per day! So the “simple” and clear step was to build automatic micro-climate control “things” begin with automatic windows openers.

The physical environment (from big to small):

- 200 meters long, 10 meters wide and 4 meters high half-circle production area

- Any number (26 in my case) of windows along at the top of the structure

- 400 (2×200) meters long, 4mm thick steel leading wire to attach to the control arms of the windows. One of the 200m line is the opening line the other is the closing line.

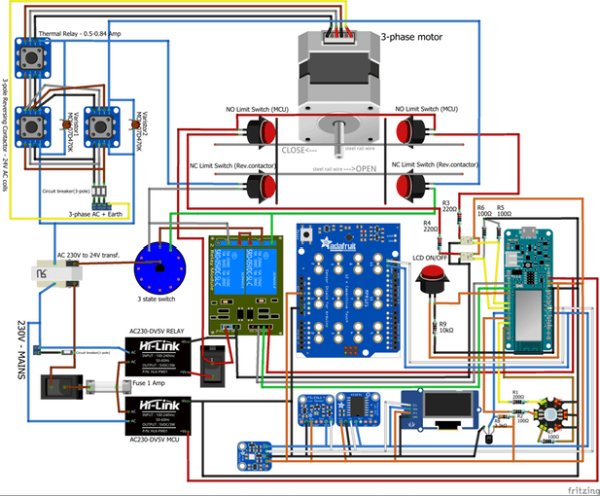

- The leading wire is attached to a 3-phase motor assembled with a worm gear unit. The steel wire lines are twisted around the axis of the gear unit clockwise and counter-clockwise. If the motor rotates clockwise then one line of wire moves one direction and the other one moves opposite.

- Different rotation is managed by a 3-pole reversing contactor assembled with a thermal relay set to the motor’s parameters. The contactor has two 24V AC coils. Coils can be powered with a 230AC to 24V AC transformer through a 3-way selector switch (OPEN or CLOSE) where the third position is for the AUTOMATIC control. For limiting the amount of opening and closing movement (no to destroy the structure by the gear) two limit switches have been put near the steel wire rail.

BIG “How to” questions for automatic micro-climate control

- … How to decide what kind of climate is need for the plants during 24 hours whole year…?

- … How to manage system stability in an airspace where humidity can be 100%, temperature can be 60 Celsius degree and huge EMI pollution (3-phase motor, contactor, pumps and relays for irrigation, etc.) all around…?

- … How to protect structure, and parts if malfunction hits…? Have experienced when a motor-gear-unit crushes the structure. No one should see that…

- Etc…

A little recollection

During last 2 years I had several phases of this project. For example it was a dead end using plastic cases. High humidity and sunlight can be harmful. All the 1602 and 2004 type LCDs with its HD44780 type controller have a high sensitivity to any kind of electromagnetic impact. After a time it just doodled random things. Not to think for future modifications can be expensive. Bought many Arduino Nanos thinking they are just fine but later I built around the MKR1000 boards. Yes they are much expensive but for IoT projects being online is essential 🙂 isn’t it?

Path believed quite good

After this long prelude lets do the workmanship (from big to small again).

I need to isolate things as much as possible from climate. Metal box is the best option I found to achieve that. I have to separate high voltage things (Supply Box) from low voltage (MCU Box) things. Two metal boxes better than one :).

Read more: Climate Cube for Greenhouse