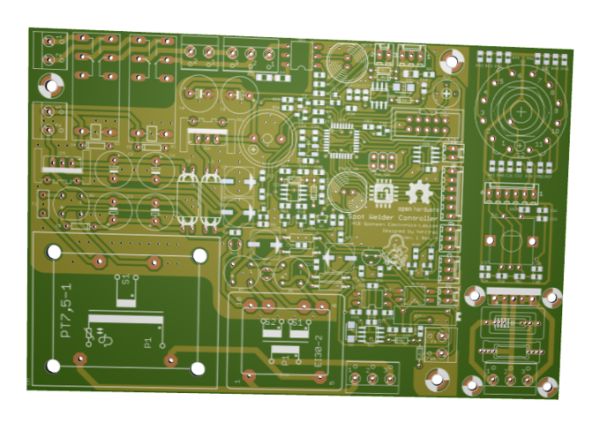

Description

I always wanted a spot welder, so I decided to built one. I wanted to build a capacitance discharge one but I couldnt afford for the capacitors at this time. So this is a controller for a dual pulse spot welder with some few extras:

– It has a zero cross detector. You could power the transformer at zero cross or dim the transformer if you like

– The transformer is triac controlled

– It has an hd44780 interface

– An spi interface for single thermocouple

– Peak detector of a current transformer

– Isolated foot switch

– Voltage monitor with opmaps

– An attempt to sense when the user tries to weld

– Single rotary switch for operation and single rotary encoder for setting up

I have used an Atmega328P and I will probably write the code in arduino IDE.

You could probably use the pcb for other applications, like:

– Ac dimmer

– Simple thermostat, or

– PID thermostat with dimming output

Further update on the project after the delivery on the pcbs

Schematics

Power Supply

The main power supply for the controller. The main transformer is 1x12VAC 1Amp (TR-15)

The PTC fuse is 0.9A with a 2W10 bridge rectifier and a 1n4007 diode, smoothing capacitors, common mode choke to remove any spikes and unwanted noise, some more capacitors, linear voltage regulator 7812 with heatsink, more caps, more chokes, more caps again, 7805 and 5v rail.

The T7 is a 2n3904 npn transistor that senses both of the AC zero crosses for the dimming circuit.

The other transformer is a 2x9Vac 0.1Amp for the secondary isolated circuits

For more detail: MCU Controlled Spot Welder