Making it easier to assemble electronics. Holds everything in place while providing full access to the work. Open source flexibility.

Overview

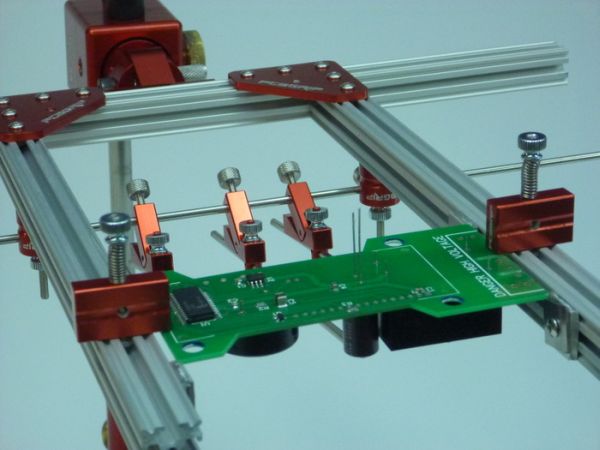

PCBGRIP is an electronics assembly system designed to make it easier to assemble and work on electronics. Completely customizable, with open source flexibility, it holds printed circuit boards (PCBs), components, stencils, and everything else you need, improving both the quality and speed of assembly. It solves the challenges of hand electronics assembly faced by hobbyists, makers, and assemblers.

Unlike other products that just hold PCBs, PCBGRIP holds PCBs and everything else. The open source aluminum extrusion and standard 3mm hardware allow you to build and share whatever you need to help you with your electronics project.

Background

When assembling PCBs with through hole components, you need to find a way of holding the component in place when the board is turned over to apply solder to the pad and lead. We progressed from trying to use one hand to hold the component, to taping the components in place, to building dedicated PCB specific jigs. None of these solutions are ideal and comprise the quality, speed, and flexibility required when assembling electronics projects and products. What started out as designing a better way of holding through hole components evolved into PCBGRIP, a complete system that not only holds components exactly where they need to be, but a system that can be customized to hold what you need where you need it, solving the common challenges associated with electronics assembly.

Features

Having hand assembled electronics you will appreciate the challenges of holding everything while you work soldering the components and getting at the work from the correct angle. PCBGRIP’s modular design is flexible and simplifies a variety of electronics assembly tasks, including:

- securely holding the PCB while you work on it;

- holding through hole components (even upside down) in place while you solder;

- allowing the project to be rotated, tilted, swung around, or raised/lowered, so you can get at the work;

- holding the surface mount technology (SMT) stencil while applying solder paste to the PCB;

- clamps that hold and align components;

- holds components with alligator clips exactly where needed; and

- open source flexibility allowing you to build and share the parts you need to meet the requirements of your unique electronics project.

System Design and Vision

We have designed each component of PCBGRIP to ensure all the components not only work individually but also in unison. Careful consideration was given to the physical dimensions of one part relative to the other parts and relative hole locations to maximize the number of combinations in which all of the parts can be used together. Most parts have 3mm holes and common M3x0.5 threads. There are countless ways the parts can be connected and used together – limited only by your ingenuity!

For more detail: PCBGRIP: Electronics Assembly System