Every Maker like me dream a PCB printer which can quickly and precisely convert our electronic idea into a psychical circuit board. I know there are plenty of project going on the subject. (see the end of the article) What I tried here is something different, quick and precise. If you have lots of electronic idea in your mind and most of them have a high probability of fail, the system must be quick and easy.

Like other professional methods I am using photo-resist dry film.

Start with cleaning your board. Very fine sandpaper can help you a lot. I clean up the board with isopropyl alcohol (rubbing alcohol) to remove all the dirt and oil.

After cleaning, laminate your photoresist film on the copper board. You can use office laminator or an iron for that. It is important to get a flat surface without any air bubble. Do not forget to remove the protective sheet before laminating the film. There are lots of YouTube videos on how to do that.

Everything up to here is standard photoresist film application. My method getting different from now on. As you know the photoresist dry film is sensitive to uv light. So we can use a DLP projector which is modified to get smaller image. I am working on DLP 3d printers so I have one in my hand ? The main idea here is modifiy the distance of the projector optics to get smaller image. My Projector is XGA 1024×768 I can get 50 microns XY resolution because of the optic modification. I heard about some projectors which can display images without any modification. Please comment on the article if you know the brand and the model name.

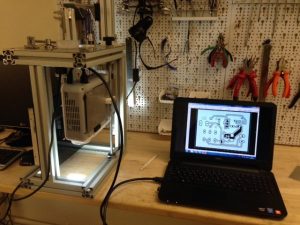

I inverse the projector upside down. Because my setup is a DLP 3d Printer. I adjust the distance to get fine clear projection. After that I export the eagle design as PDF and inverse the colors. The white parts of the objects will cure the photoresist and this parts of the circuit will stay. I draw lines distanced as 1 cm and project that image on a ruler. I try to get the correct zoom factor in order to mach the image lines and the lines on the ruler. So that I am sure the image projected is scaled 1-1.

The next parameter to predict is the exposure time. I am myself is an engineer and I know I can calculate the energy need to cure the photoresist but I do not have enough information and the datasheet of the photoresist as well as the projector. The second best engineering way is trial and error. I made some exposure tests between 10 to 180 seconds and I got an information of 20 sec is more than enough for this parameter. Please see my trail and error test results below.

Read more: Making circuit boards with DLP projector