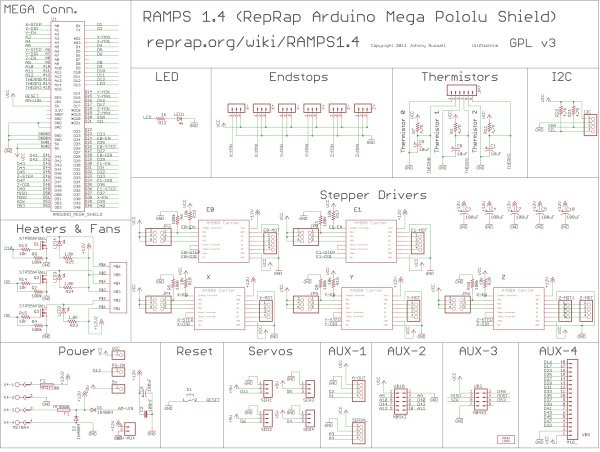

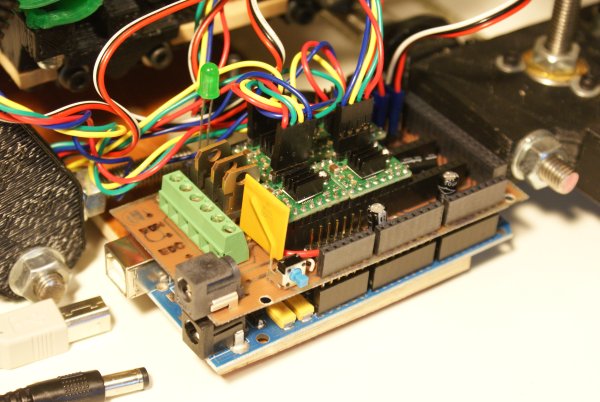

RepRap Arduino Mega Pololu Shield, or RAMPS for short. It is designed to fit the entire electronics needed for a RepRap in one small package for low cost. RAMPS interfaces an Arduino Mega with the powerful Arduino MEGA platform and has plenty room for expansion. The modular design includes plug in stepper drivers and extruder control electronics on an Arduino MEGA shield for easy service, part replacement, upgrade-ability and expansion. Additionally, a number of Arduino expansion boards can be added to the system as long as the main RAMPS board is kept to the top of the stack.

This board is mostly based on Adrian’s Pololu_Electronics and work by Tonok. Copper etch resists methods suggested by Vik. Also inspired by Vik’s work with EasyDrivers. Circuit design based mostly on Adrian’s Pololu_Electronics. Joaz at RepRapSource.com supplied initial pin definitions and many design improvements. Much inspiration, suggestions, and ideas from Prusajr, Kliment, Maxbots, Rick, and many others in the RepRap community.

Features

- It has provisions for the cartesian robot and extruder.

- Expandable to control other accessories.

- 3 mosfets for heater / fan outputs and 3 thermistor circuits.

- Fused at 5A for additional safety and component protection

- Heated bed control with additional 11A fuse

- Fits 5 Pololu stepper driver board

- Pololu boards are on pin header sockets so they can be replaced easily or removed for use in future designs.

- I2C and SPI pins left available for future expansion.

- All the Mosfets are hooked into PWM pins for versatility.

- Servo style connectors are used to connect to the endstops, motors, and leds. These connectors are gold plated, rated for 3A, very compact, and globally available.

- USB type B receptacle

- SD Card add on available — Available now made by Kliment – Sdramps

- LEDs indicate when heater outputs on

- Option to connect 2 motors to Z for Prusa Mendel

Source

| FILE ID# | TYPE | DESCRIPTION | DOWNLOAD |

|---|---|---|---|

| File:ArduinoMegaPololuShield.zip | Eagle Files | These are the files you need to make the board.(Use the File: link to the left to access older versions of the file.) | media:ArduinoMegaPololuShield.zip |

| File:RepRapjr.lbr | Eagle Libraries | The components used in this board are here. see Eagle_Library | media:RepRapjr.lbr |

Custom Versions

Custom Versions

Grogyans

Will have locking connectors for the motors. Uses the MAX6675 thermocouple sensor, which essentially replaces the AD595. Less vias, which should also increase building time. Bottom only, to enable the possibility of a RepRap or toner transfer method to fabricate the board. Moved the power LED to the front for easy identification. Providing the user has a proto-shield for Mega, there is plenty of pins left for them to play with. By using another tiered board, will alow the possibility of more extruders and LCD all of which can communicate over the I2C protocol.

For more detail: Arduino Mega Pololu Shield