You might remember my first set of lights that I put on my dad’s skates. Well those weren’t bright enough and they were a lot of work because I didn’t know how to make PCBs. In this i’ble I’ll cover how to make your own custom PCBs in under an hour! Keep in mind, if you’ve never made a PCB before it isn’t hard at all! This would be a good beginner project to get started with making PCBs. All it takes is a trip to an office supply store and to a radioshack! See, I never got around to making PCBs because I didn’t want to have to go to the store and buy etchant and stuff, you know what I mean. Eventually I just made myself do it and it was the best electronic skill I learned for a while! So quite being lazy and go get some PCB material!

Below is the link to my first RGB skate-shoe lights, which doesn’t require making a PCB.

http://www.instructables.com/id/RGB-LED-Skate-Ligh…

I hope you enjoy this i’ble and please cast it a vote!

Step 1: Ingredients:

Electronics:

- Arduino

- ATtiny2313 or similar IC

- 20 DIP IC socket

- Breadboard

- Jumper Wires

- 4x AAA battery holder

- 4x 2N222A NPN transistors

- 4x 1kΩ resistors

- 4x 100-150Ω resistors

- 5x red LEDs

- 5x green LEDs

- 5x blue LEDs

- 5x yellow (or white) LEDs

- Heat Shrink

- Non-conductive material, such as cork board.

Materials for Etching:

- Copper Clad

- Etchent

- Iron

- Laser Printer

- Photo Paper (the same shiny paper you would get your pictures on from a pharmacy)

- Paper towels

- Surgical Gloves

- Rag

- Plastic Tray

- Steel wool soap cleaning pad

Tools:

- Dremel or Drill (Dremels work better because they are much lighter and have way higher RPMs)

- 1/32 bit for Dremel or drill

- Soldering Gun

- Double-sided Tape

- Electrical Tape

Step 2: Files

First you will need to download these images and this Arduino sketch, unless you would like to make your own sketch.

Even though I already know that this circuit works, it’s always a good idea to breadboard it first. That way you can learn to prototype your circuits! The next step includes the circuit, so you can prototype like 1 row and see how it works or something like that!

Step 3: Schematic

Terms: I/O = Input/Output

Here is the schematic. Now I wanted to run 5 LEDs off of 1 pin, but I couldn’t just hook them all up to the same pin on the ATtiny2313! If you look in the datasheet is says, “40mA per I/O pin”. Lets do a little math! 5 Leds @ 24mA a piece is 5 x 24mA = 120mA. This means when all 5 LEDs are on, they are using 120mA, which is 80mA over the absolute maximum working load of the I/O pin. So to fix this I use a 2n2222A NPN transistor as a switch. When a small current is applied to the base of the NPN transistor it connects the all the LEDs to ground, thus completing the circuit. The transistor barely uses any current, so this considerably lightens the load on each I/O pin.

Step 4: Making Your Own Easy PCB! Part 1: Printing

This will be a slighty condensed version of making PCBs. I will make an I’ble very soon with a full video and instructions soon. You will be able to find it here http://www.instructables.com/member/Enjoying+Electronics/.

Some other good i’bles on this topic are

http://www.instructables.com/id/Mostly-easy-PCB-ma…

http://www.instructables.com/id/Sponge-Ferric-Chlo…

http://www.instructables.com/id/Turn-your-EAGLE-sc…

Print off the the circuit that I attached to this i’ble. Do not resize it or anything. Don’t reverse it. Load photo paper into your printer’s bypass tray (if you have one). Usually in the bypass tray they have two little tabs for you to adjust the paper constraints. Since photo paper is small, you will need to push the constrains most of the way in. You will now need to find out which side of the paper your laser printer prints on. Usually you will face the side you want printed on downwards, so print it off circuit onto the shiny side of photo paper and trim the edges on the lines I provided.

On a blank sheet of paper, print off the silkscreen, and trim it on the guide lines. This will show you which electronic components go where. It’s quite important!

Step 5: Making Your Own Easy PCB! Part 2: Preparing the Copper Clad

Using the schematic as a template, cut to size a piece of copper clad. Then using a very fine grit or

steel wool with a dab of soap clean off the copper to roughen it up just a bit and to get rid of any grease or dirt.

Step 6: Making Your Own Easy PCB! Part 3: Ironing

Place the cleaned copper on a flat surface, such as a desk, then put schematic face down on top of the copper. Remember, the shiny side should have the circuit on it, and that gets pressed against the copper. Lay a piece of paper towel over the paper and the copper. This will keep your iron clean.

Set the iron to it’s highest setting, and set it on top of the paper

towel that is covering the photo paper. Press down on the iron for about 1.5 minutes, without moving the iron. Do not slide the paper around or you will not get a clean ink transfer. After 1.5 minutes, pick up the iron gently and rotate the iron a little bit then press down evenly for another 1.5 minutes. Make sure that you get the corners ironed well. Now that you are done ironing, the paper will be sticking to the copper. Be careful; the copper is hot.

Don’t worry, you won’t set the paper towel on fire, it’s actually kind of difficult to do that!

Step 7: Making Your Own Easy PCB! Part 4: Cleaning

Carefully transport the copper clad with the paper stuck on top of it into a pot of warm water. This will soften the

paper and make removing it easier. Don’t stick the hot copper plating into cold water because it will begin to warp. Gently begin peeling off the paper. Start from the corners and peel slowly. You should be able to peel off the top layer leaving a very thin layer hugging the copper. I found that rubbing my thumb in circular patterns works best. If a couple bits of the ink come off that’s OK, we can fix it with a sharpie.

Wash the board.

Next inspect your board. You need to make sure that you get all the paper off. If you look very carefully between thin traces and pads that are in close proximity of each other you might notice tiny bits of paper residue between them. That has to go, or else the copper under it won’t etch very well, leaving the two traces connected. This could result in a short circuit, ruining your parts, so make sure to get up all that paper! Fix any broken traces with a sharpie. Get the finest-tipped sharpie you have. Draw in the missing lines and let the ink dry. Repeat until the traces are completely black.

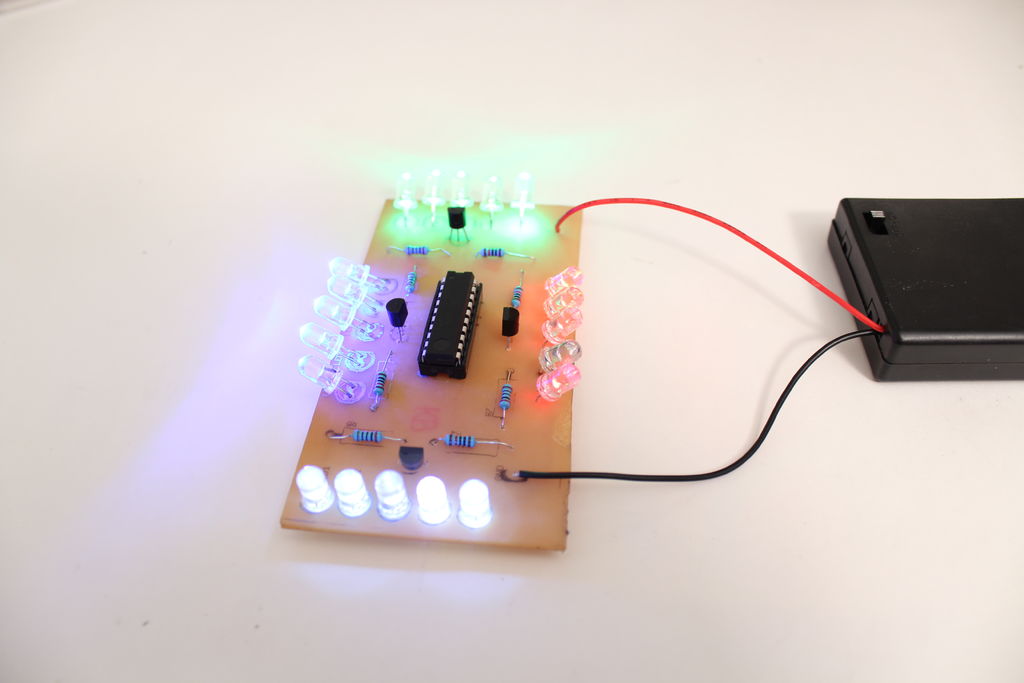

For more detail: DIY Super Bright LED Skate Lights